Innovation

When the market speaks, Greene Tweed listens.

When our customers requested a material capable of withstanding the high temperature high pressure (HTHP) environments found in the Oil & Gas markets, we listened; Greene Tweed applications engineers understand how a combination of pressure and temperatures could lead to excessive creep in thermoplastic materials, resulting in failure and costly downtime.

Knowing that a material with greater temperature resistance and strength under pressure could enable the customers’ goals of drilling into deeper reservoirs, we set to work. In 2013, Greene Tweed introduced the market’s first cross-linked PEEK: Arlon® 3000XT. Not only did Arlon® 3000XT feature a glass transition temperature 35°F (20°C) higher than PEEK polymers and superior mechanical property retention from 350°F (177°C) to 600°F (316°C) – it also enabled our customers to exceed the design limitations of PEEK.

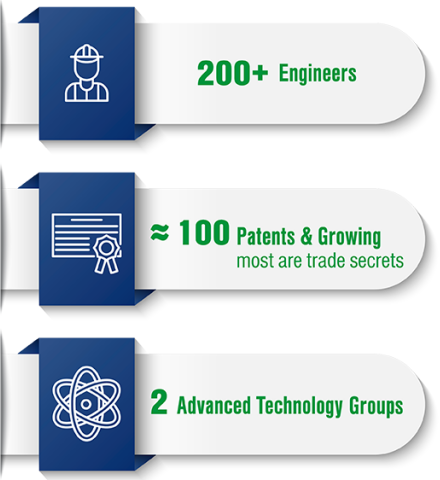

Greene Tweed has been on the leading edge of product development for 160 years. Our engineers collaborate closely with customers to understand how to best push their technology to achieve goals faster, with greater efficiency and reliability. Our materials and product portfolio attest to our commitment to innovation.

A wide-ranging portfolio of Chemraz® perfluoroelastomers reduces seal failure thanks to chemical compatibility and high temperatures in a variety of applications across multiple industries. WR® and AR® materials offer a second life to aging equipment by increasing efficiency and performance over standard metal components.

And when it comes to putting materials to work in the field, Greene Tweed’s team of application engineers understands what it takes to ensure reliability under critical operational factors including temperatures, fluid compatibility, and pressure. Our expertise in materials and applications combine to develop innovative solutions that optimize the performance of our customers’ equipment.

Greene Tweed is recognized for its GT Ring design, now commonly known as the t-seal, which is relied upon in a variety of applications. Our engineers innovated the use of Arlon® PEEK bodies in electrical connectors in our Seal-Connect® product line which allows for greater pin density and superior insulation resistance over glass-to-metal connectors. Our structural components, molded out of our Xycomp® thermoplastic composites and Arlon® thermoplastics, consolidate multiple parts into a single component to reduce both inventory stocking concerns and weight.

Innovation is more than a tradition at Greene Tweed; it’s a commitment to our customers’ future. When it can’t fail, choose Greene Tweed.