Product Details

Metal Strength at a Fraction of the Weight

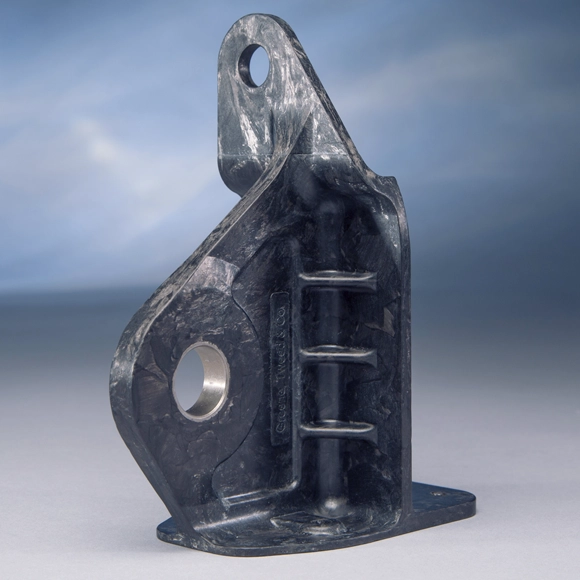

If you need a lightweight alternative to metal components that can hold its own in extreme conditions, parts produced from Xycomp® DLF™ are the solution. This high-performance thermoplastic composite is designed to replace complex-shape metallic components for aerospace and defense, space, industrial, and other applications.

With a high fiber content, Xycomp® DLF™ components meet FST (flame, smoke toxicity) standards and 15-minute burn-through requirements, all while weighing up to 60% less than their metal counterparts. They are ideal for use in aircraft, engines, aerostructures, and mobility platforms.

Features and Benefits

- Up to 60% weight reduction

- Fatigue, vibration, and impact resistance equal to or better than metal

- Excellent property retention at elevated temperatures

- Chemical resistance to all common aerospace fluids

- Consolidates complex assemblies into fewer parts via a net molded solution

Industries & Applications

Better than Metal

Xycomp® DLF™ thermoplastic composite components are designed to be used across a wide range of applications valuing strength and weight optimization. No matter how demanding the environment, our team works with you to co-develop an optimized and custom solution for your needs.

Applications include:

- Nacelle and engine components

- Interiors

- Aerostructures

- Industrial machinery

- Robotics

Reliable Performance

Xycomp® DLF™ is field-tested for performance and durability in extreme operating conditions with proven aerospace pedigree. Please contact us to learn how Greene Tweed thermoplastic Xycomp solutions can work for you.