Product Details

High-Performance Connectors for Demanding Applications

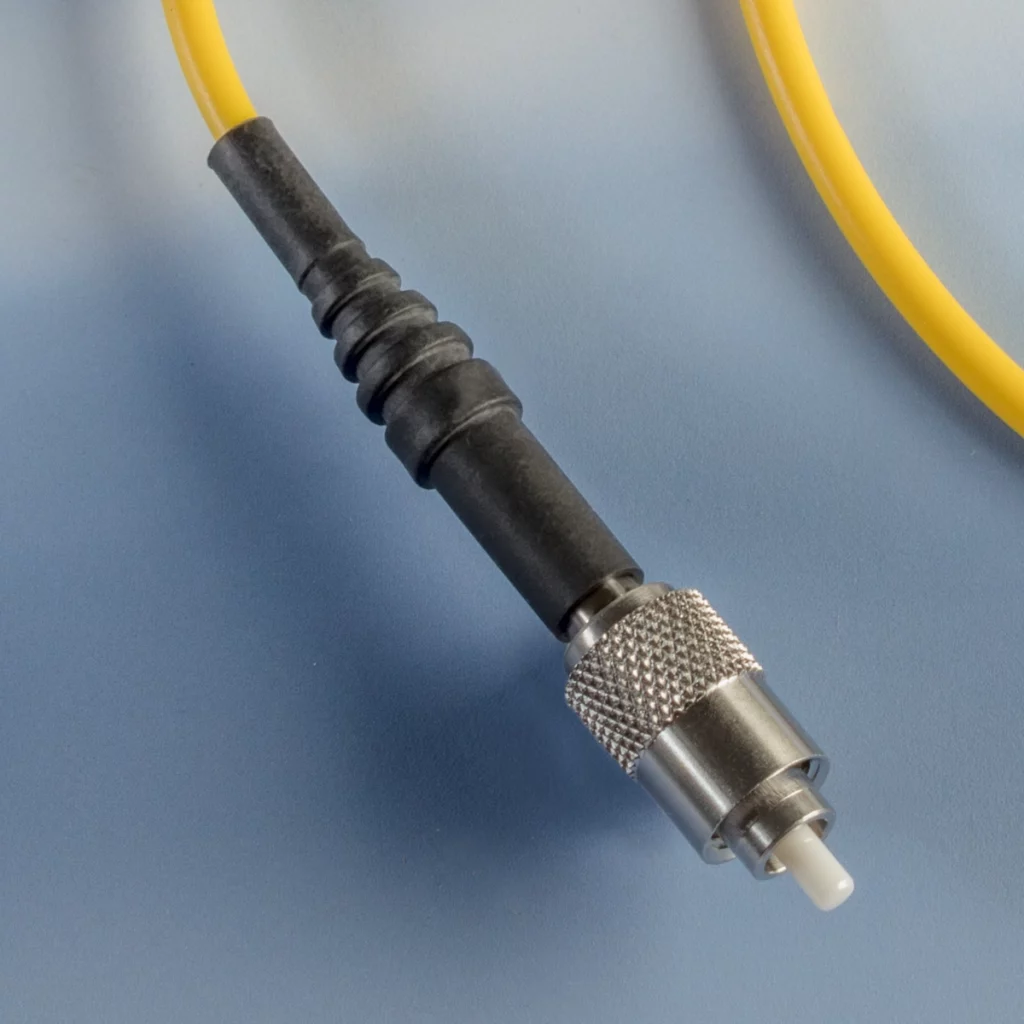

Greene Tweed’s FC connectors use a threaded position keyed coupling connection while our ST connectors feature a bayonet twist-lock (j-slot) connection. Combined with the precision-machined zirconia ferrule/alignment sleeve, these connections ensure perfectly reproducible termini alignment in even the most demanding conditions.

When used with an FC adapter, ST adapter, or Permanent Bulkhead Feedthrough (PBF), they provide a hermetically sealed connection protected from wet environments and particulates that can irreversibly degrade optical fiber.

Dry HP Series

The DRY™ HP Series is used in harsh environments where assemblies are likely to be submerged in water or subjected to rain, ice, high humidity, or temperatures from -55°C to 85°C (-67°F to 185°F). All FC and ST connectors have passed stringent immersion and heat/humidity tests with minimal light loss.

Certificates & Patents

Seal-Connect® Electrical Connectors – Protected by U.S. Patents 7,249,971, 7,442,081

Additional patents may be pending in the U.S. and elsewhere.

Benefits & Features of Fiber Optic Connectors

Compatibility

- Universal threaded position keyed coupling works with single- and multi-mode fibers (FC)

- Universal bayonet twist-lock connection (ST)

- Connector kit is supplied without fiber.

Environmentally Sealed

- No signal degradation

- Effective sealing action eliminates damage from moisture or particulate

Tested & Approved

- Clarity of signal

- Tested from -55°C to 85°C (-67°F to 185°F) and subjected to stringent heat/humidity with 0.5 dB maximum insertion loss

- No water penetration to affect signal

Product Specifications

- Ferrules are precision-machined zirconia

- Boot fits 3mm OD optical cable

- Made from high-quality, corrosion-resistant materials

- FC DRYTM is nickel-plated brass; FC-DRYTM HP is 316(ruggedized) series stainless steel

- Typical light loss is less than 0.5 dB

Let's Connect

Reach out to learn how Greene Tweed connectors can support your application needs.