Dynamic Product Applications

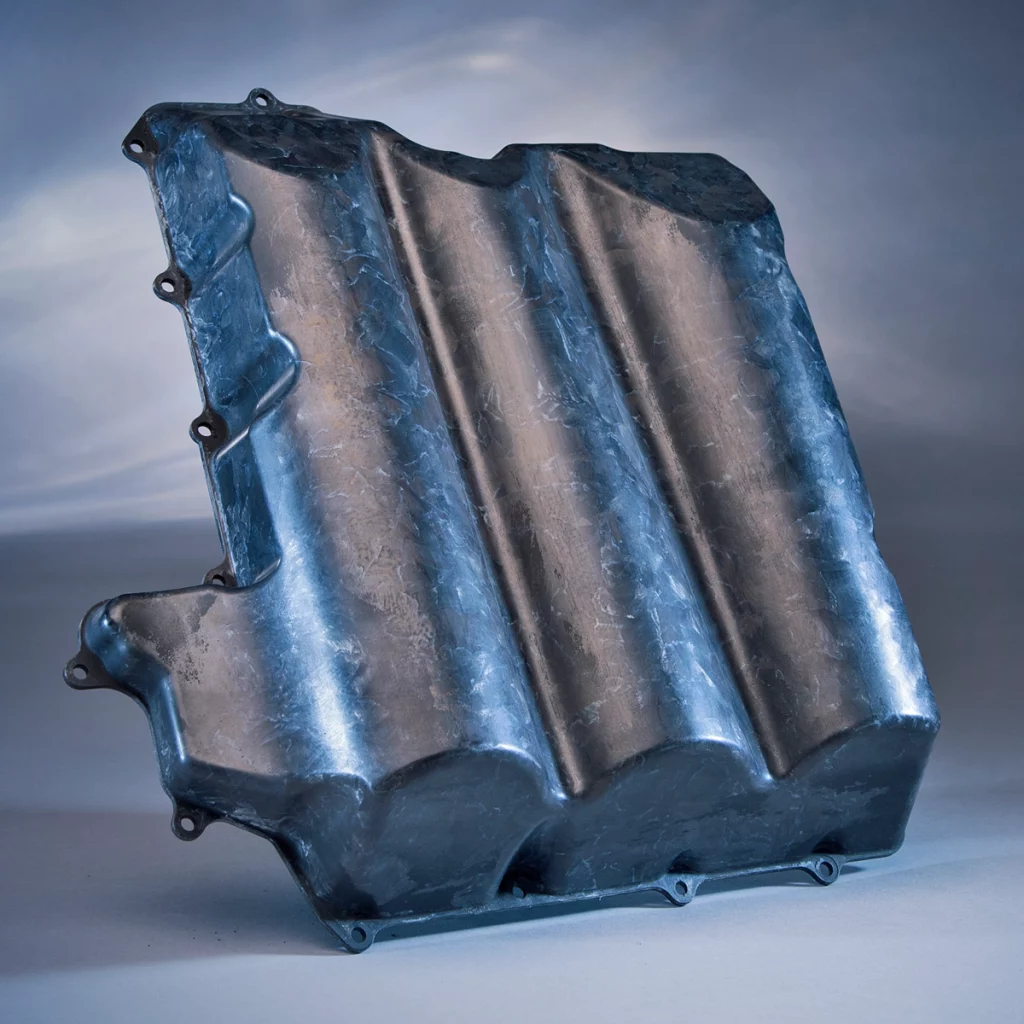

Brace for Impact

Fire, Smoke, and Toxicity (FST) are no match for these CNC machined metal replacement parts. Benefits include quality mechanical performance, creep resistance, and extreme temperature capability for critical applications.

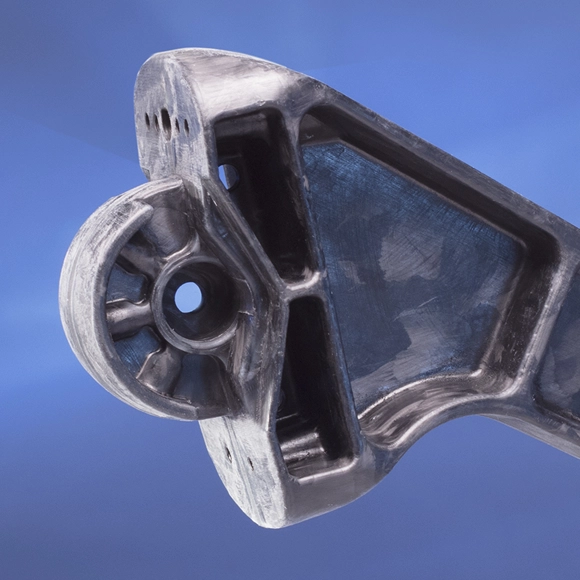

Superior Resistance to Wear and Tear

Greene Tweed components are CNC machined metal replacement parts that optimize mechanical performance, impact resistance, temperature capability, EMI/electrical properties, and FST (fire, smoke, toxicity) resistance.

Operational Stability Where You Need it Most

Greene Tweed components deliver proven mechanical and FST performance and resistance to hail impact, erosion, and bird strikes. These solutions are ideal for CNC machined metal and lay-up composite replacement parts.

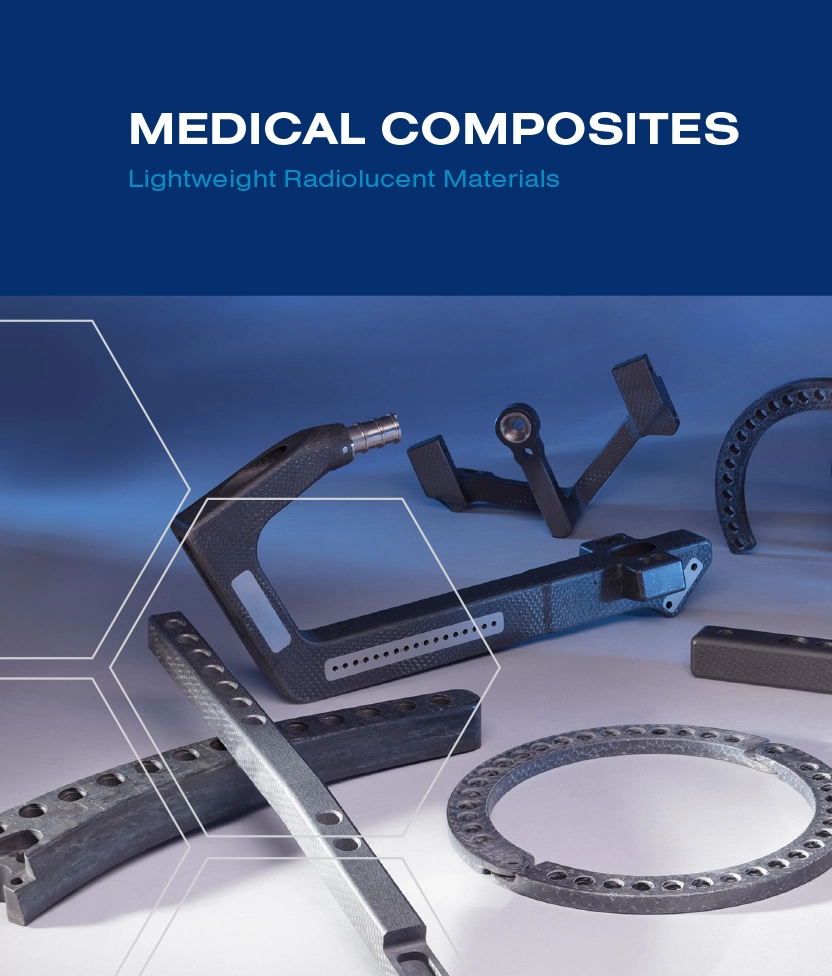

Premium Precision

Greene Tweed components provide superior strength, radiolucent properties, and environmental resistance when compared to their metal counterparts. Customers can expect reliable stability – even after repeated sterilization autoclave cycles.

Your Next Structural Components Solution

Reach out to learn how Greene Tweed's products can support your application needs.