Industrial Operations

Industrial Solutions for When it Can’t Fail

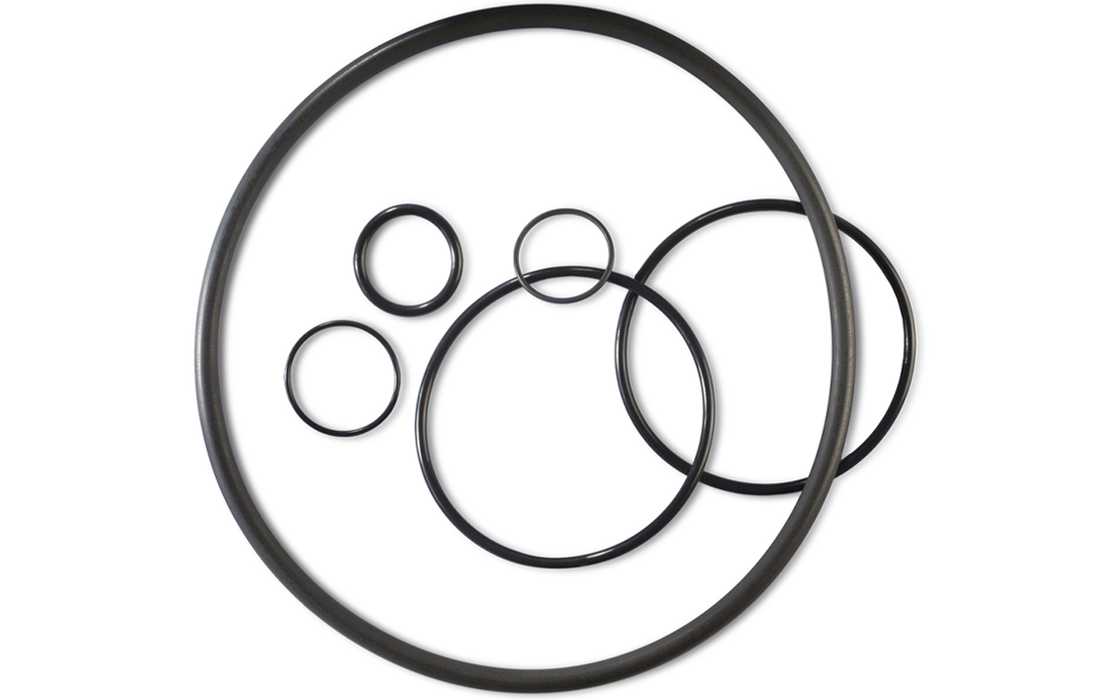

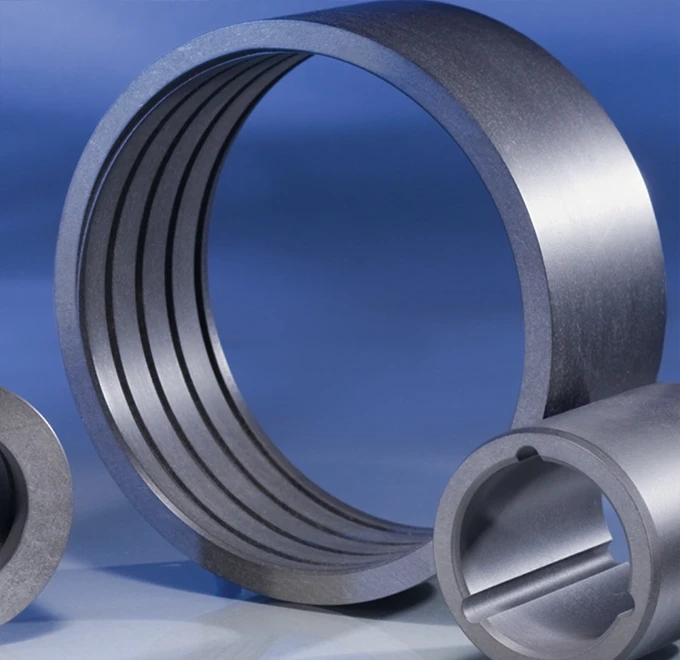

Designed for Harsh Environments.

Built for Reliable Performance.

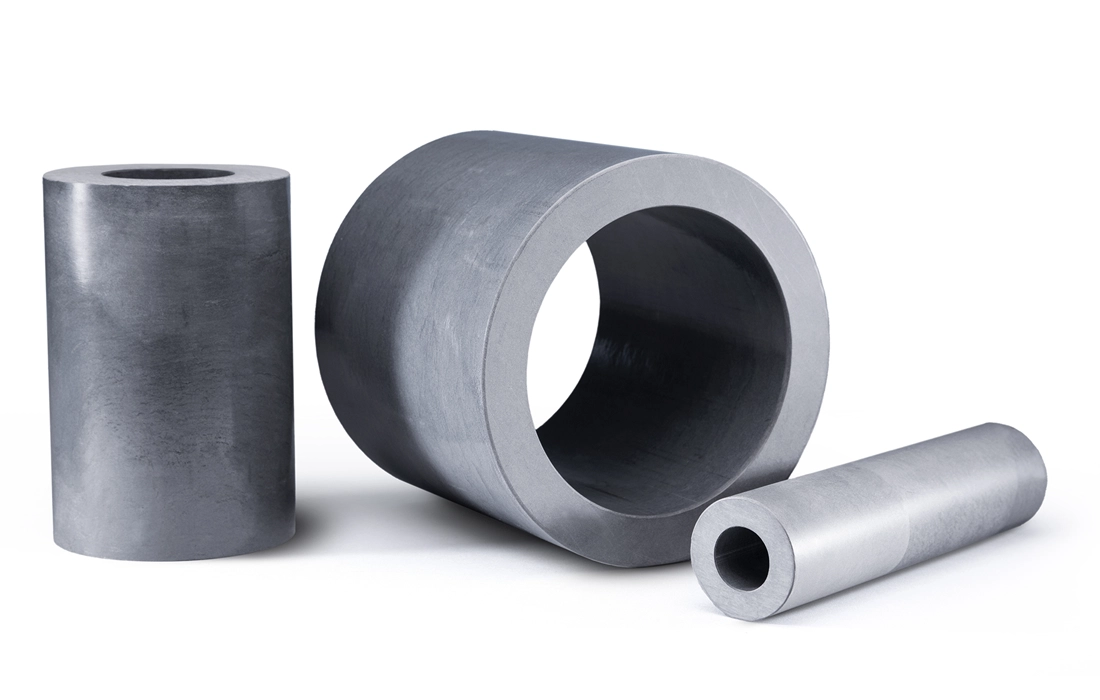

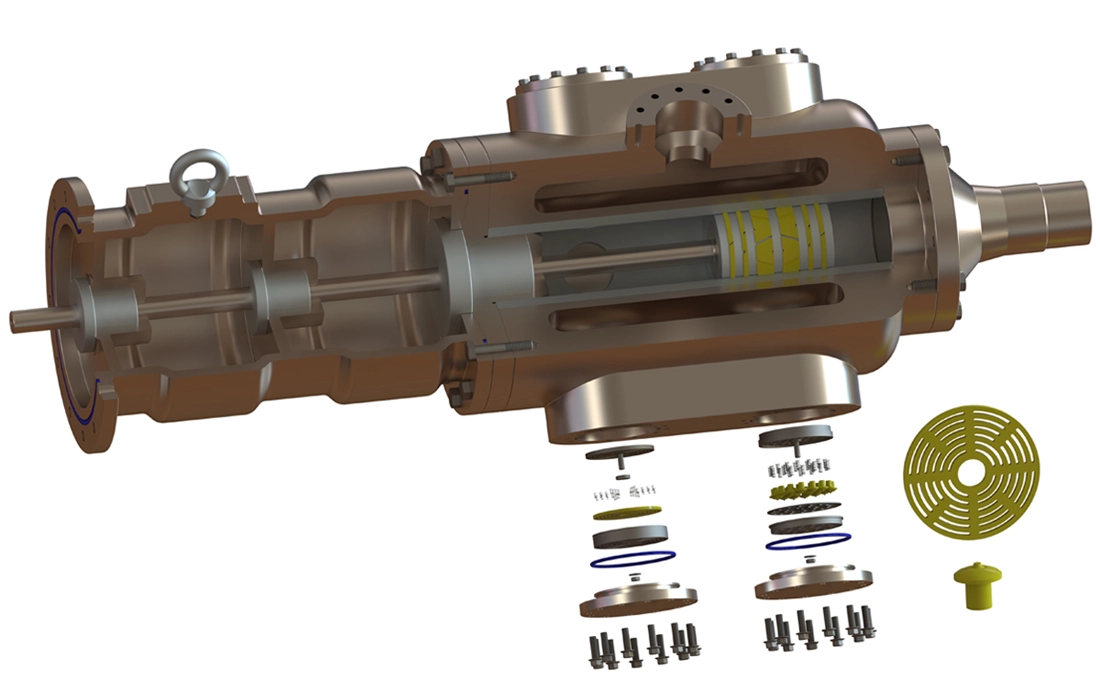

Greene Tweed delivers custom-engineered solutions for industrial operations, excelling in the harshest conditions to improve safety and efficiency, while reducing downtime and environmental waste.

Over 100 patents backed by field-tested performance.

Over 160 years of innovation in industrial applications.

Additional Resources:

Solutions You Can Count On, Expertise You Can Trust

For over 160 years, Greene Tweed has provided industries worldwide with reliable, custom-engineered solutions.

From advanced materials to innovative designs, we help our customers achieve operational excellence while improving safety and sustainability