A Winning Combination

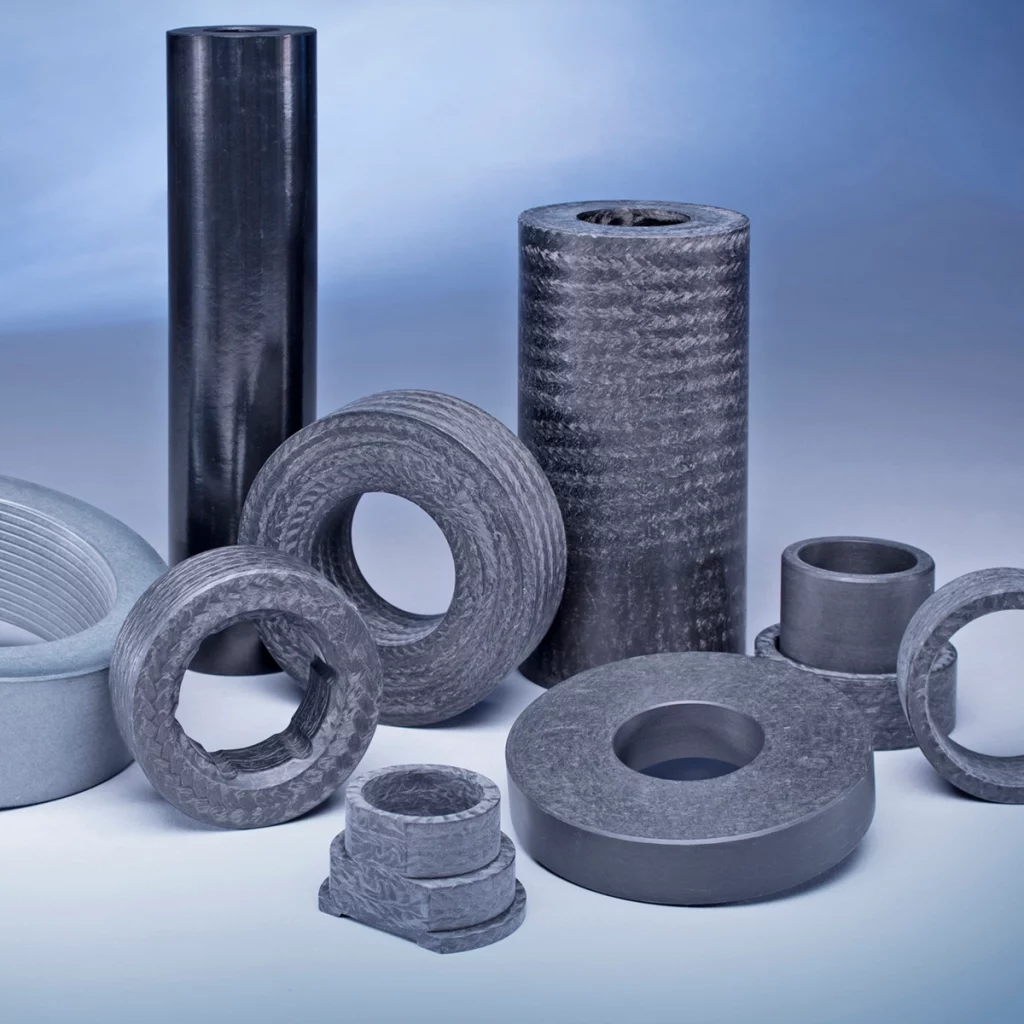

Thermoplastic Composites for Demanding Applications

Greene Tweed thermoplastic composite materials deliver proven mechanical strength, reduced wear, part consolidation, environmental/chemical resistance, and weight reduction across a wide range of components and applications. For a composite solution built to weather the elements, our design engineers work with you to determine the best product design and material for the job.

Thermoplastic composite materials include PEEK (Polyetheretherketone) and PEKK (Polyetherketoneketone), PEI (Polyetherimide), PFA (Perfluoroalkoxy), PTFE (Polytetrafluoroethylene), and PA (Polyamide or “Nylon”).

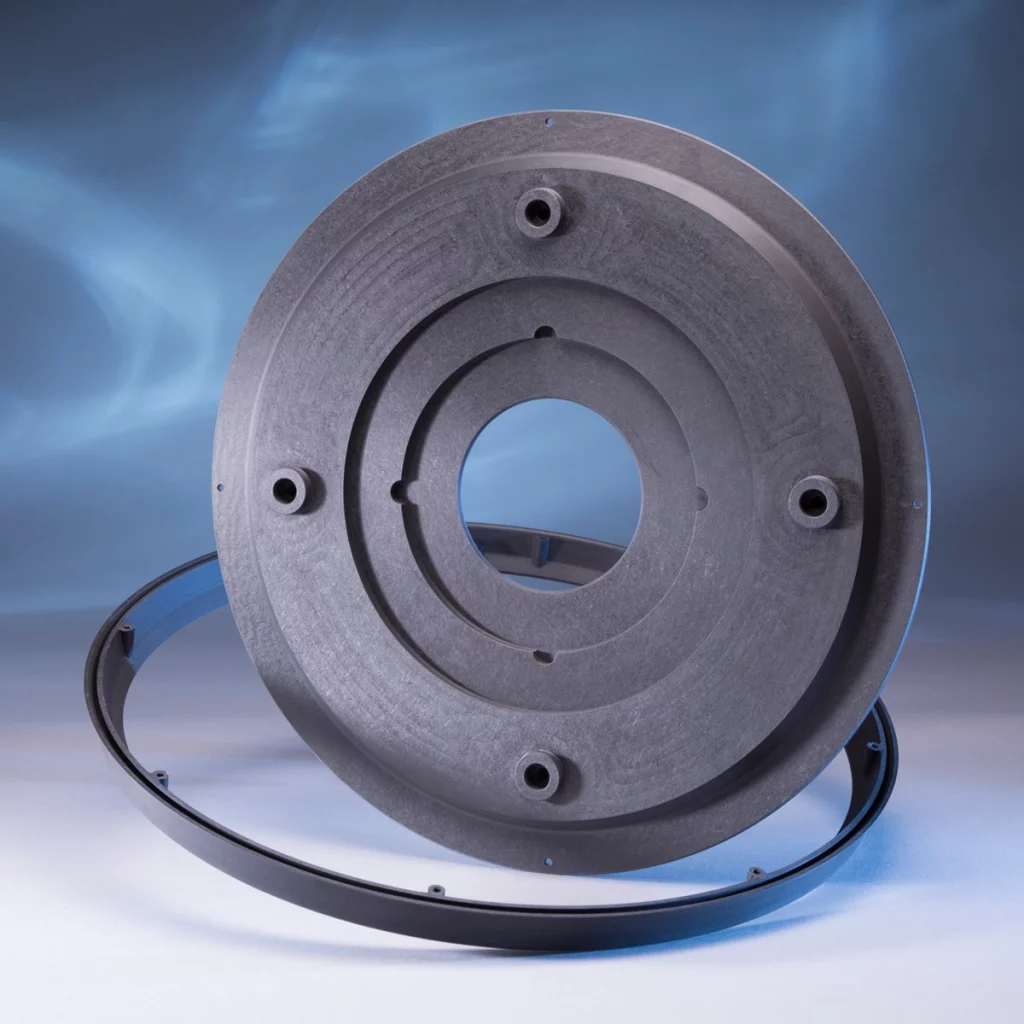

Improve Uptime, Reduce Maintenance

Greene Tweed’s AR® (Abrasion Resistant) protects pump systems from sand, coal ash, and other solids. AR® components are designed to operate in extreme temperatures, from subzero up to 121°C (250°F).

AR® 1 provides general abrasion resistance typically used in vertical pumps, while AR® HT is more suited to high-temperature, abrasive-resistant applications like vertical water feed pumps in nuclear facilities.

For a detailed look at AR® capabilities, explore our Thermoplastic Composite Chemical Compatibility guide.

High-Performance, Low-Cost OEM Solutions

ONX® 600 is used in precision engineered components for semiconductor manufacturing. This material provides a resilient wafer cleaning solution able to withstand corrosive chemicals at high temperatures. ONX® 600 is electrically conductive, removing static charges caused by spin-spray actions and protecting the delicate features of semiconductor devices.

Superior Metal Replacement

For a high-strength, lightweight, chemical-resistant material built for demanding medical and biotechnology applications, look no further than Orthtek®. While metals have traditionally been used for structural components in medical/x-ray technology, Orthtek® structures are radiolucent and provide equal or greater performance at a fraction of the weight. These composites are engineered using selective carbon fiber reinforcements and thermoplastic polymers to achieve maximum strength and toughness.

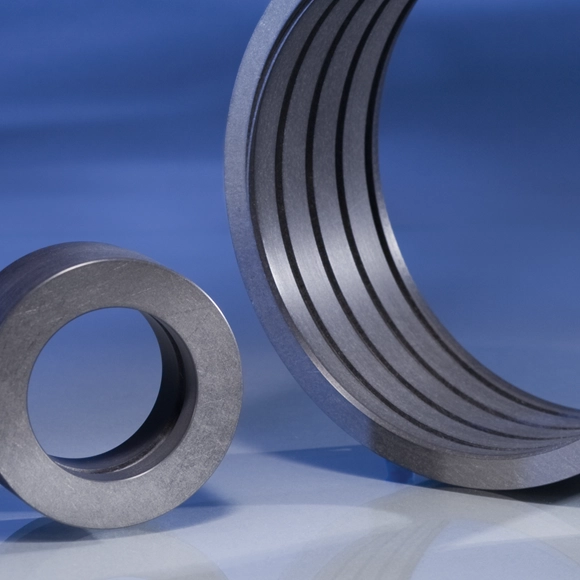

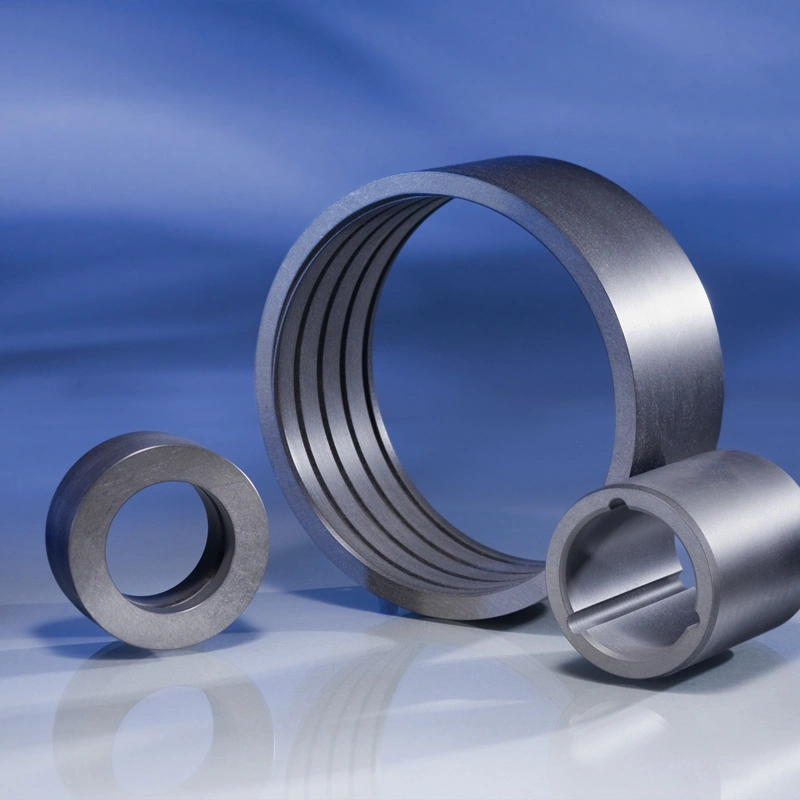

Minimize Wear and Friction

Greene Tweed’s WR® (Wear Resistant) line improves uptime and extends the service life of pump wear components by reducing wear and friction while delivering superior non-galling, non-seizing performance. With longer dry runs and exceptional chemical resistance, WR® materials reduce running clearance by over 50% for improved stability and overall efficiency.

For a detailed look at WR® capabilities, explore our Thermoplastic Composite Chemical Compatibility guide.

Metal Strength at a Fraction of the Weight

Xycomp® DLF™ is a lightweight alternative to metal built to handle extreme conditions. This high-performance thermoplastic composite is replaces complex metallic components for aerospace and defense, chemical processing, space, industrial, and other applications.

Xycomp® DLF™ components meet FST (flame, smoke toxicity) standards and the 15-minute burn-through requirement, all while weighing up to 60% less than their metal counterparts. They are ideal for use in aircraft, engines, and other aerostructures.