Chemical Processing

Industries - Industrial Operations

Chemical Processing Applications and Solutions

Innovative Products

Seals, structural components, wear parts—Greene Tweed improves performance in your industrial applications. Market leading OEMs around the world trust our expertise when it comes to reliable and durable products.

Years of technical experience and innovation

For more than 150 years, customers have relied on Greene Tweed to increase meantime between repair (MTBR) and increase operational safety and environmental compliance.

Our seals, engineered components, and thermoplastic composite wear parts deliver proven performance in aggressive media such as hydrocarbons and aromatics, ethylene oxide, inorganic bases, solvents, steam, oxidizing acids, alcohols, sour gases, and amines. Our solutions are found in equipment commonly used in chemical processing including compressors, pumps, mixers, centrifuges, filtration systems, instrumentation, mechanical seals, and valves.

Expert Application Engineering

Compressors

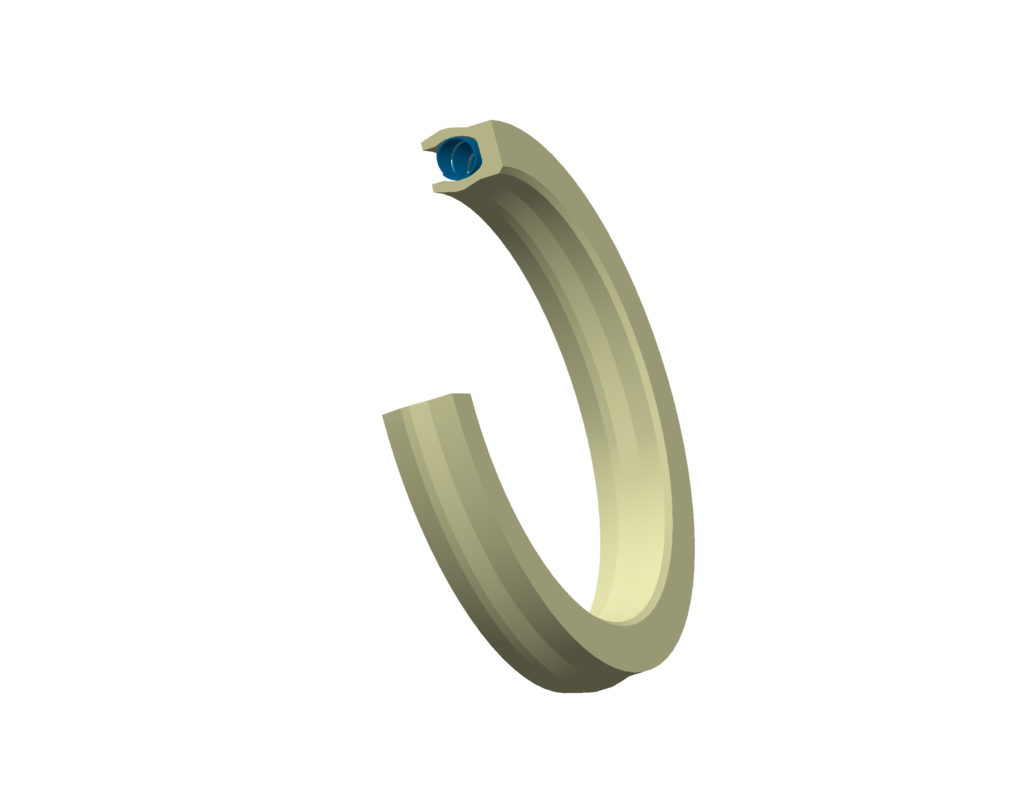

A Greene Tweed seal in a centrifugal compressor can help increase reliability and efficiency. Our portfolio includes a variety of geometries, including MSE® lip seals, labyrinth seals, and o-rings. Through careful material selection, seals are optimized for chemical resistance and temperature to minimize the likelihood of unplanned downtime. Our elastomer portfolio includes grades of Chemraz® FFKM and Fusion® FKM qualified for rapid gas decompression (RGD) under the ISO 23936-2 testing standard.

Greene Tweed can provide machined Arlon® and Avalon® parts for use in reciprocating compressors. Products include piston and rider rings, valve plates, and valve poppets.

Sealing Solutions for Harsh Chemicals

Aggressive solvents damage traditional solutions and risk premature failure. Optimize performance with our Chemraz® perfluoroelastomers and Arlon® PEEK thermoplastics. They offer near total protection against chemical attack. Even in extreme temperatures and harsh environments.

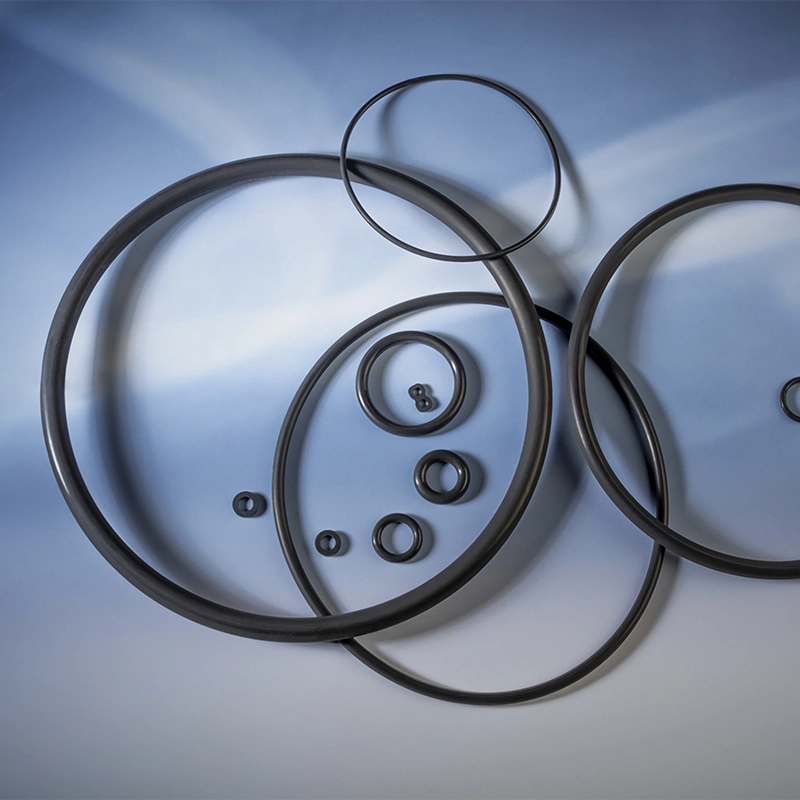

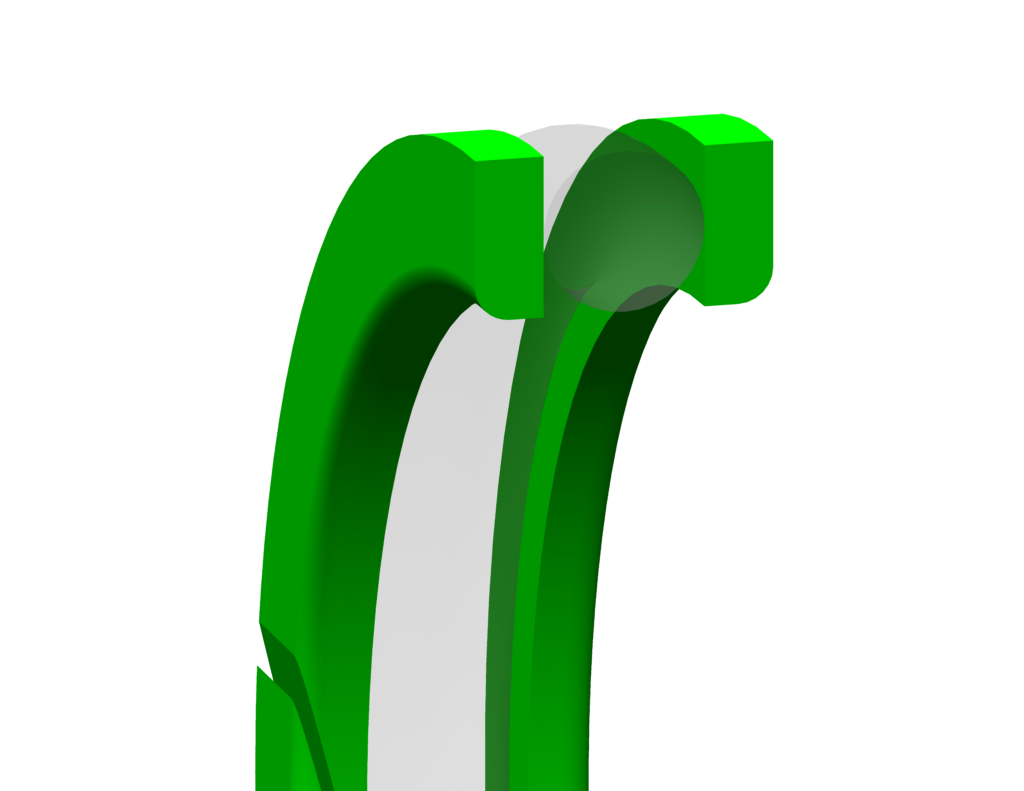

Pumps, Cylinder Seals, Wear Rings

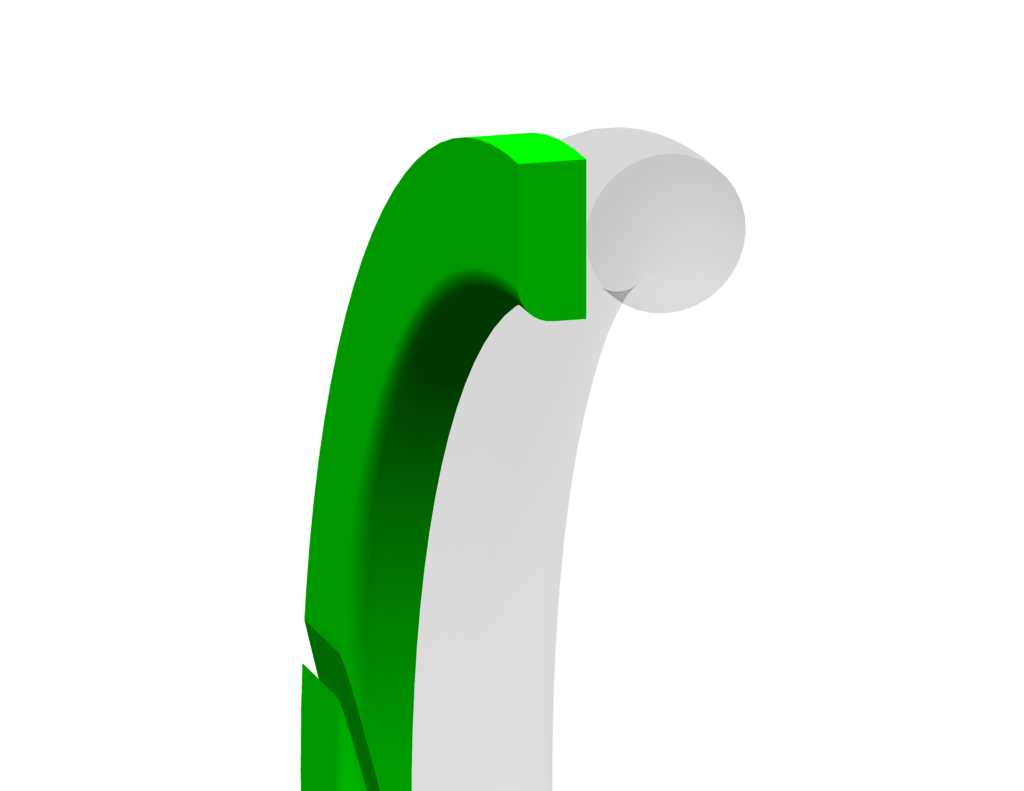

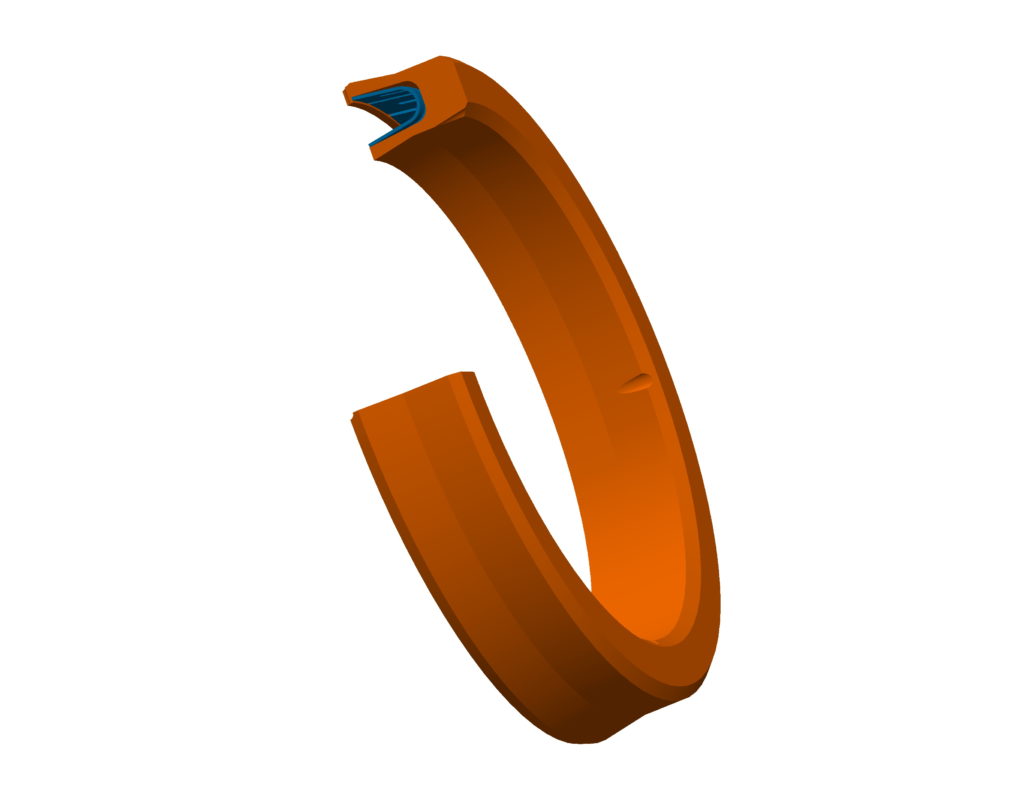

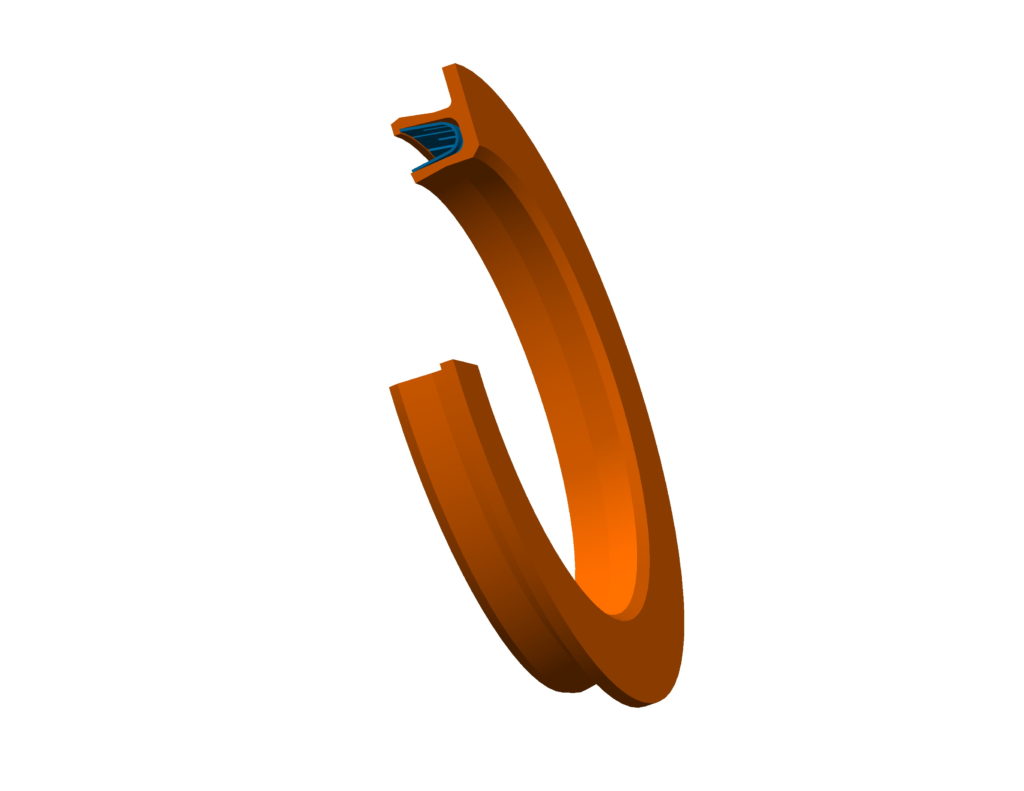

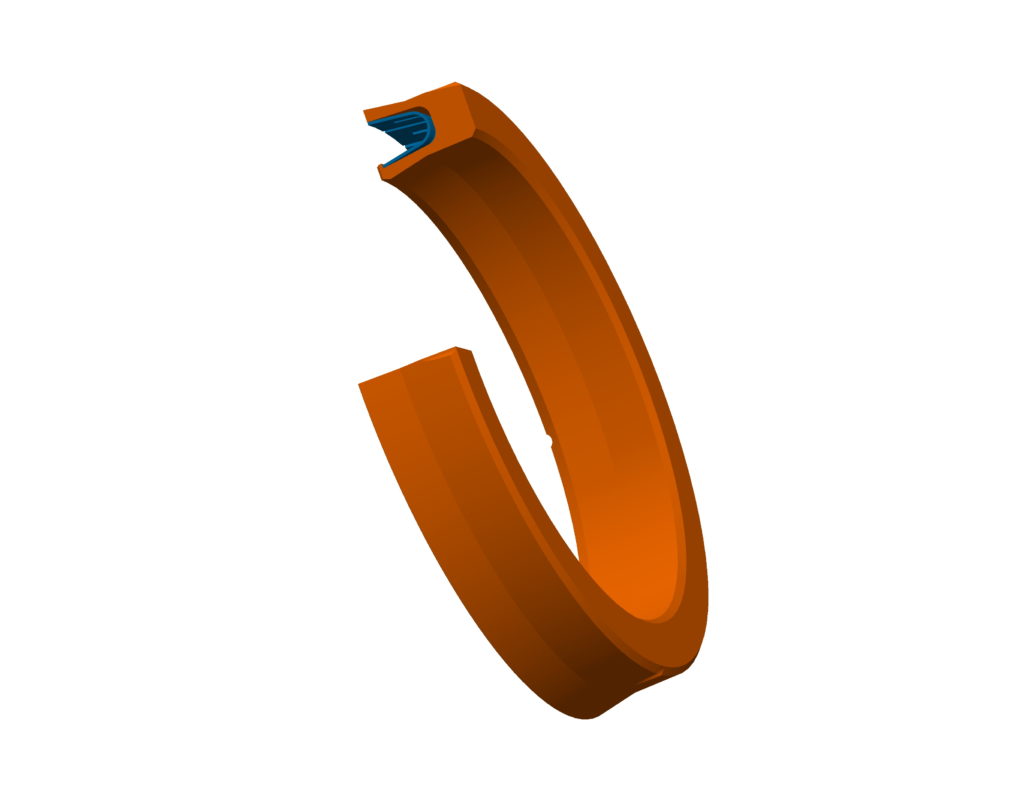

Greene Tweed manufactures seals from proprietary elastomeric and thermoplastic materials in designs ranging from standard O-rings to custom-engineered seal stacks for complex applications. We primarily offer five core types of seals for the chemical industry: O-rings, G-T® rings, MSE® seals, seal stacks, and capped seals. And for niche applications, we’ll work with you to design a custom-engineered sealing solution tailored to your needs.

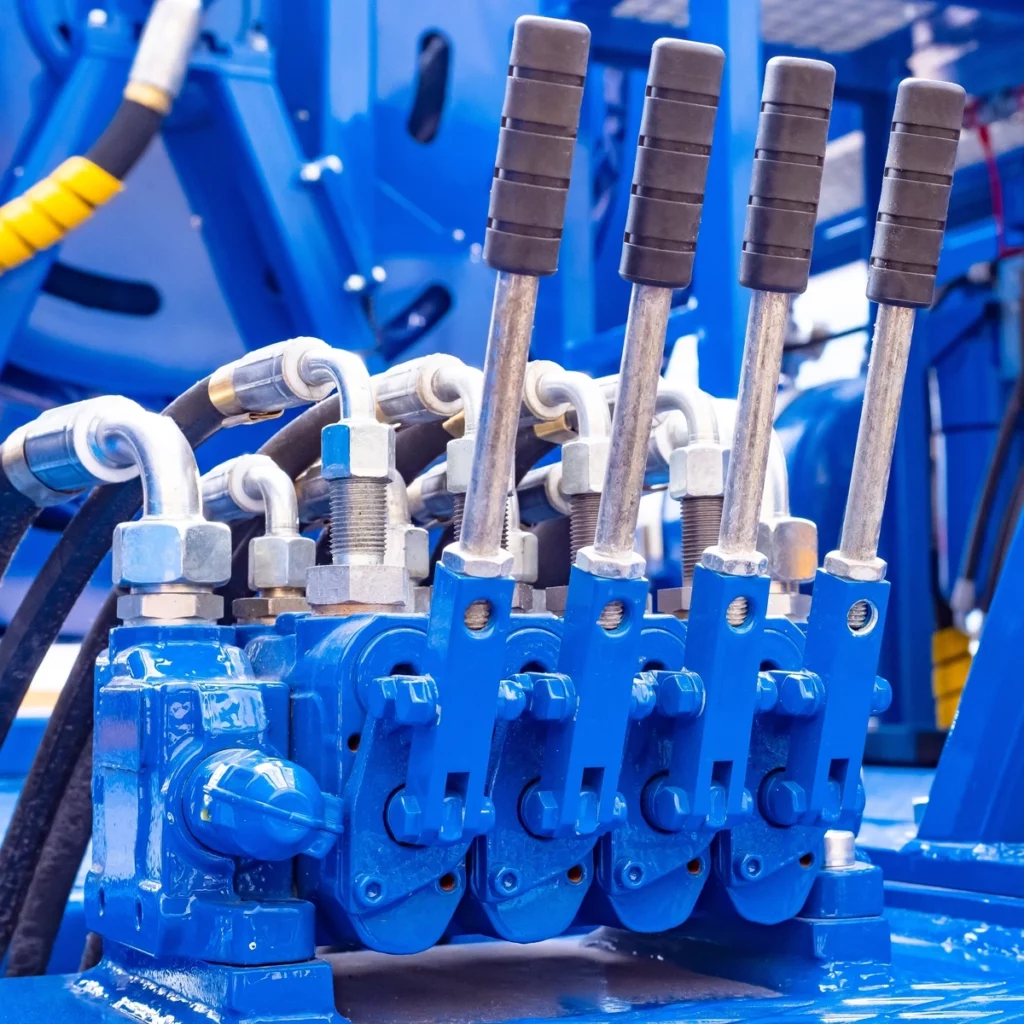

Pumps & Valves

Greene Tweed pump components are made from our high-performance thermoplastic composite materials for centrifugal pumps and seal-less (magnetic drive and canned motor) pumps. They are used in chemical plants, refineries, petrochemical plants, and power generation plants worldwide.

Our valve components, backed by more than 30 years of design experience, reduce leakage and fugitive emissions to optimize performance in valves, taking media, temperature, and pressure – among other factors – into consideration.