Aerospace & Defense

Aerospace & Defense

Mission critical

performance solutions

Innovative Products

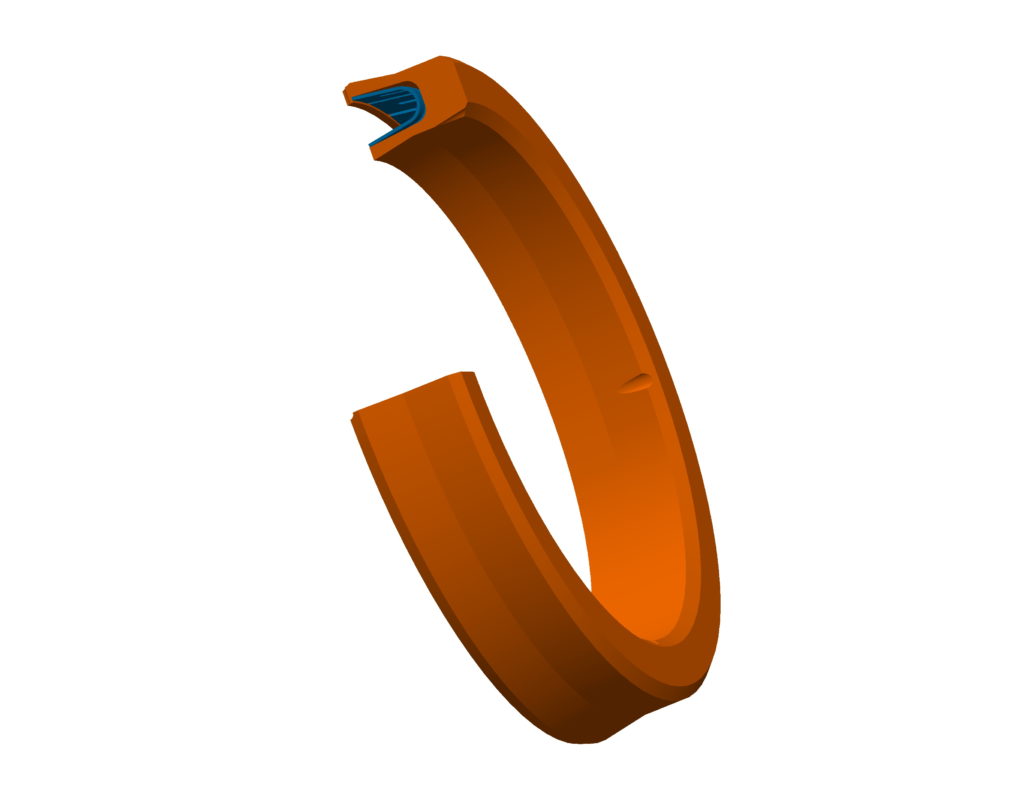

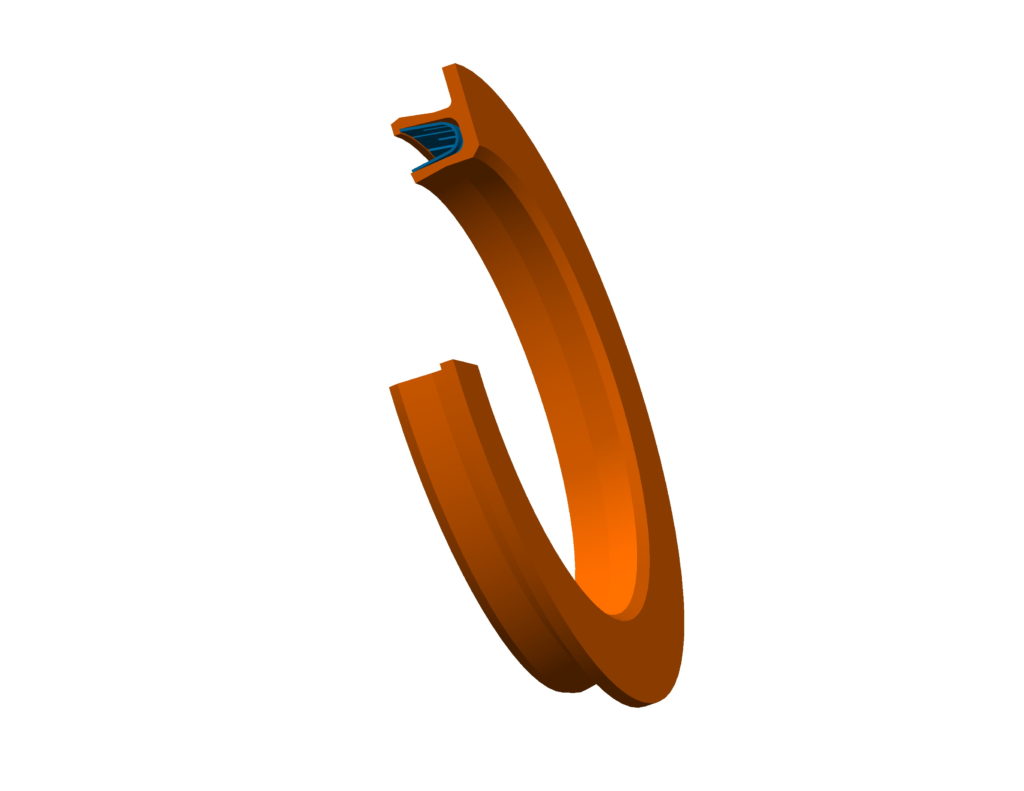

Transfer energy. Keep fluids in and contaminants out. Prevent components from wearing out. We build our Aerospace and Defense sealing systems to withstand the pressure of harsh environments.

of the world's commercial and military aircraft rely on Greene Tweed’s custom engineered components.

Greene Tweed is the recognized leader in high-performance solutions for Aerospace and Defense.

With over 50 years of proven experience in the Aerospace industry, Greene Tweed engineers are experts in designing and developing innovative solutions for applications where failure is not an option, such as landing gear systems, flight control systems and engines, hydraulic utility systems, brake systems, fuel systems, and more.

Expert Application Engineering

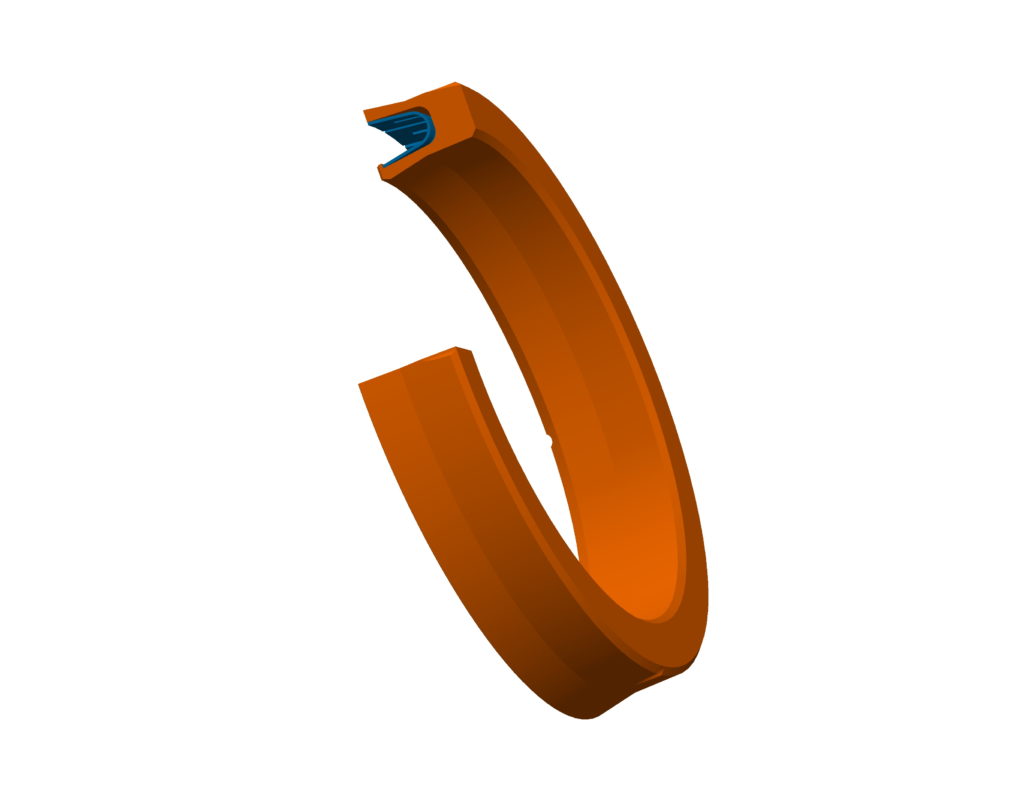

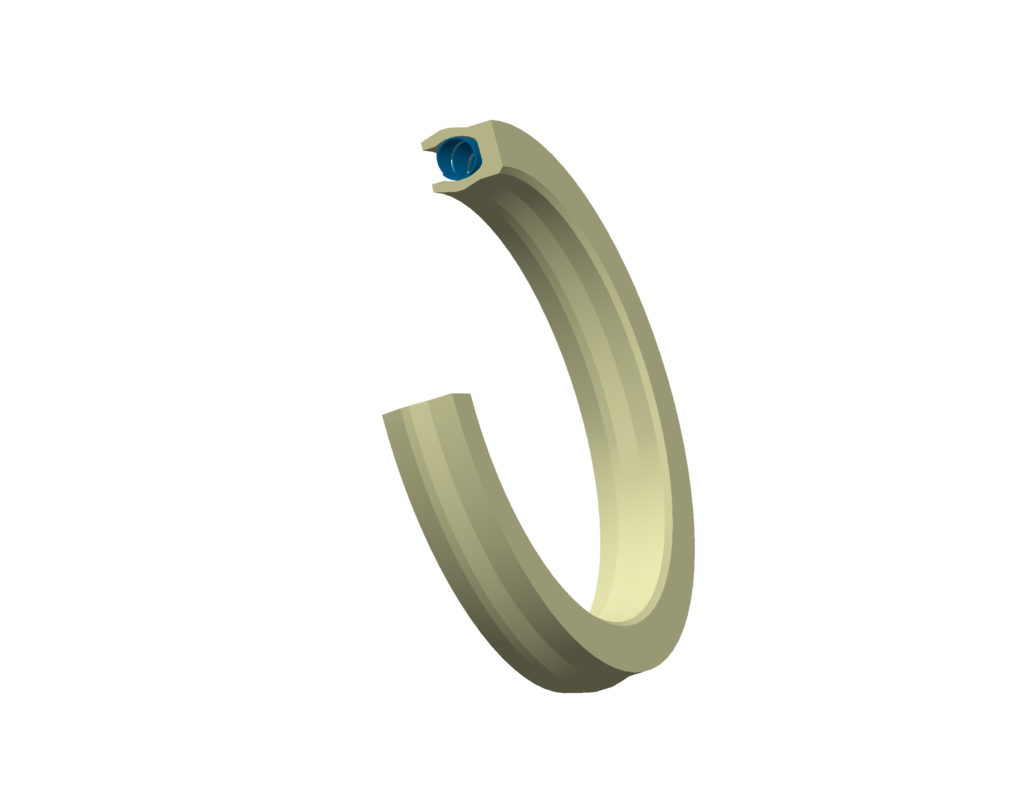

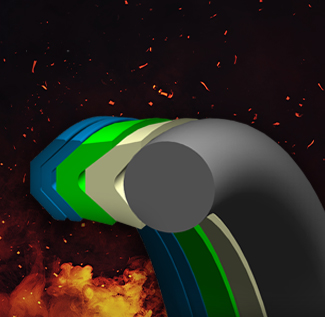

Advanced Seals for Demanding Applications

Safely and efficiently transfer energy, keep fluids in and contaminants out, and prevent components from wearing out in harsh environments with Greene Tweed’s Aerospace and Defense sealing systems.

Explore Greene Tweed’s custom engineered solutions in our interactive catalog.

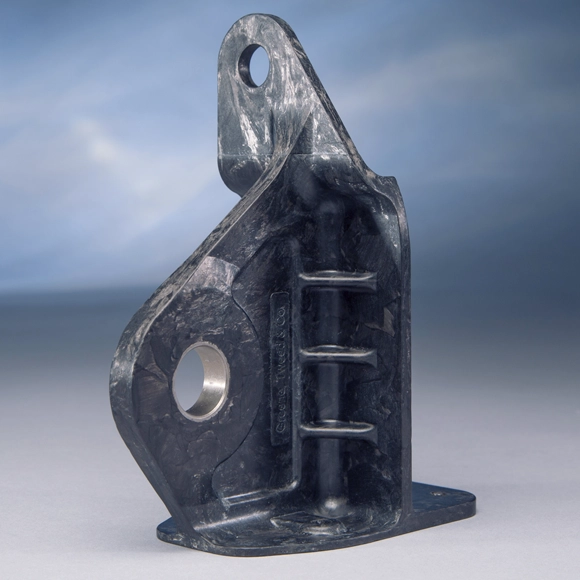

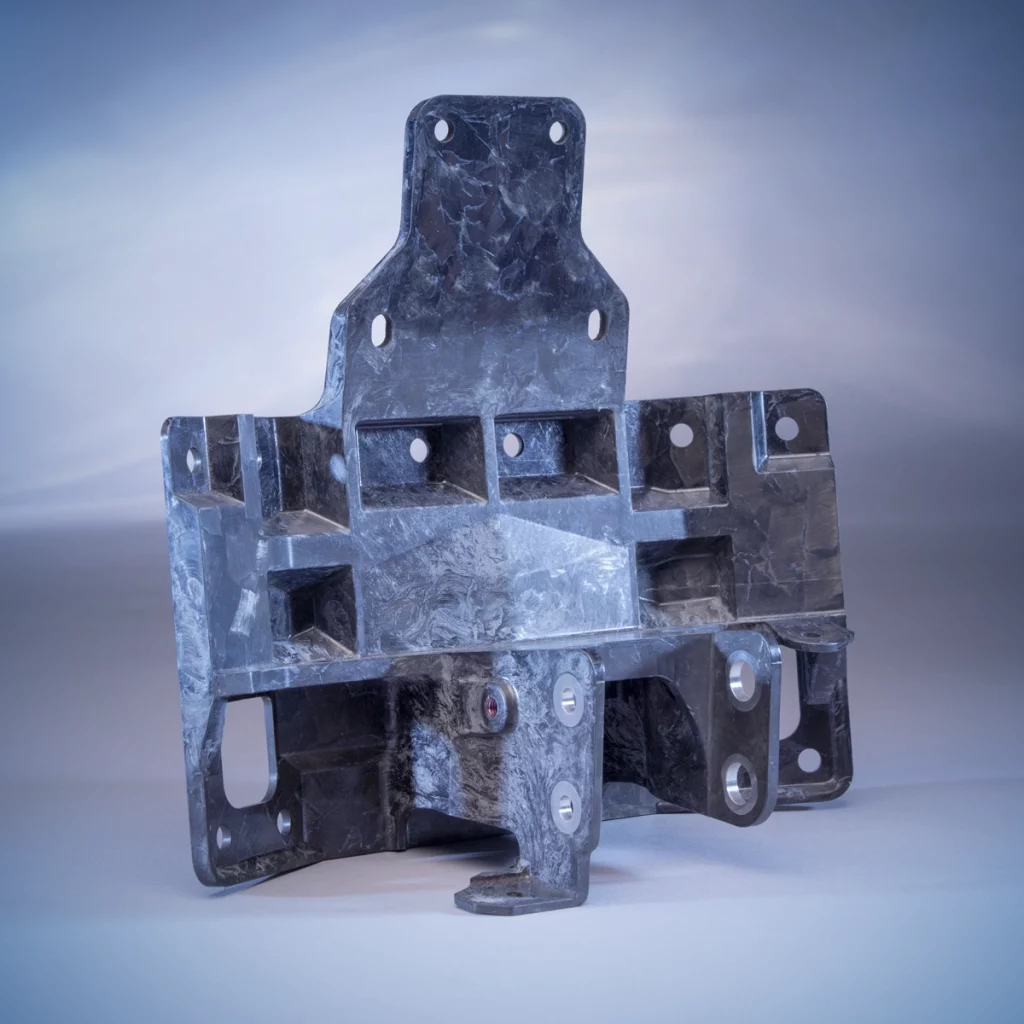

Stronger and Lighter than Metal

When it comes to Aerospace and Defense, there is no room for equipment failure. That’s why Greene Tweed manufactures high-performance thermoplastic and composite components built to perform throughout a broad range of critical applications.

Greene Tweed structural components deliver:

- Lightweight, high-performance alternative to metal parts, components, and assemblies

- Reduced part complexity and cost by combining multiple assembled components into one molded part

- Superior strength-to-weight ratio in demanding environments