Product Details

Superior Chemical and Steam Resistance

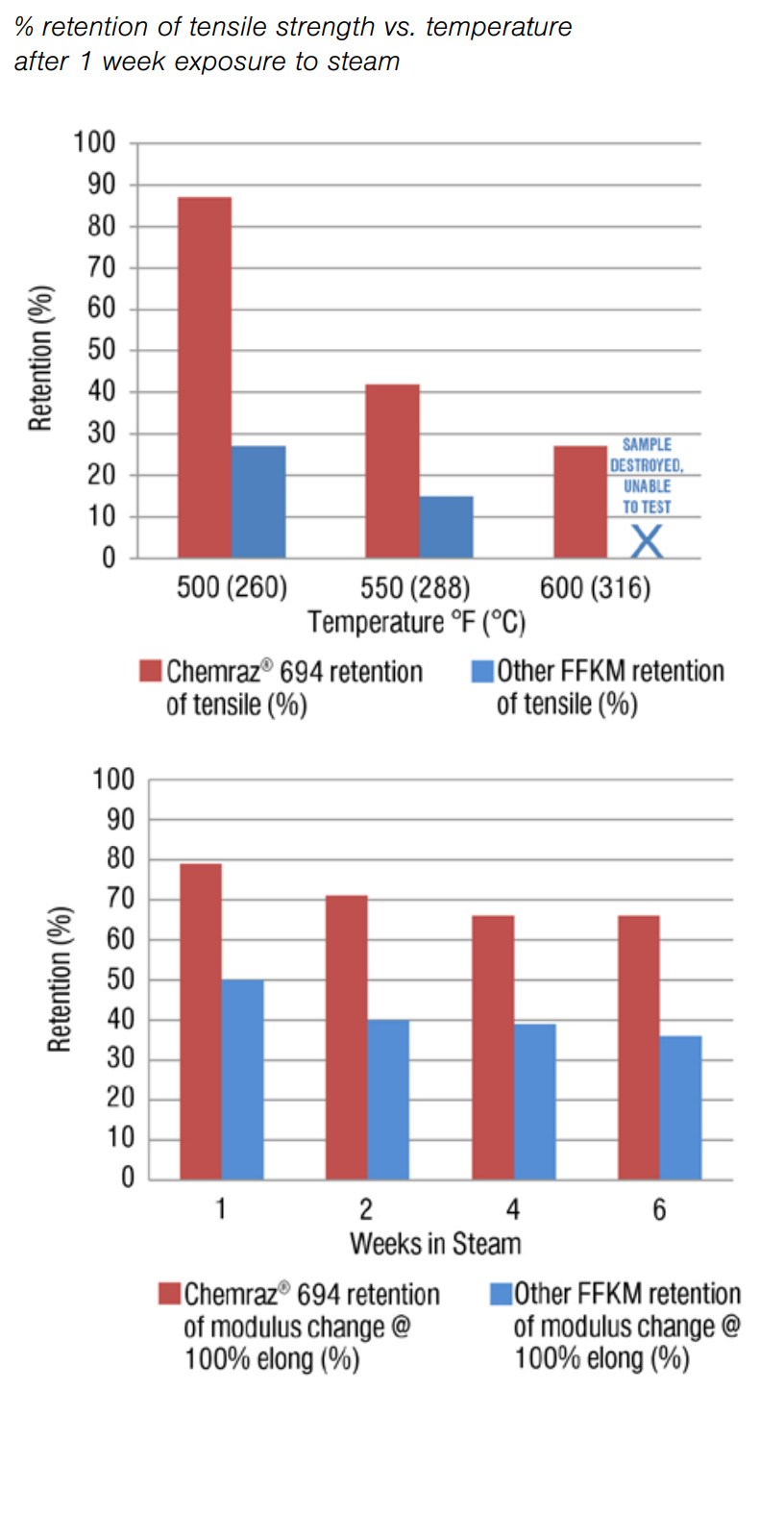

If you need custom-engineered components with exceptional chemical resistance and performance in high-temperature steam environments, Chemraz® 694 is for you. After extensive testing, this innovative FFKM (perfluoroelastomer) outperformed competitor materials after an extended time at 500°F (260°C) in steam and short-term exposure to a peak excursion at 600°F (316°C).

Chemraz 694® also delivers exceptional chemical resistance to well fluids and gases commonly found in the Oil & Gas industry, and is available in O-ring, V-ring, G-T® ring, and custom configurations.

Features and Benefits

- Retains physical properties in a hot steam environment, thus reducing mean time between failure (MTBF) of elastomeric components in critical steam environments

- Superior resistance to hostile reservoir chemistries, drilling fluid additives, and production chemicals for improved elastomeric performance

- Excellent compression set and thermal shock resistance for increased reliability of components used in critical steam and high-temperature environments

Extensive Testing & Proven Results

Industries & Applications

More reliable downhole service life

Chemraz® 694 products are designed for use across a wide range of applications in Upstream Oil & Gas. No matter how demanding the environment, our team works with you to determine the right solution for the job.

Applications include:

- Steam Injection

- Downhole

- Steam-assisted gravity drainage (SAG-D)

- Cyclic Steam Stimulation (CSS)

- Electrical submersible pumps (ESPs)

Chemraz 694® is a proven, reliable engineered component solution. It is available now in the form of O-ring, V-ring, G-T® ring, and other custom shapes.