Product Details

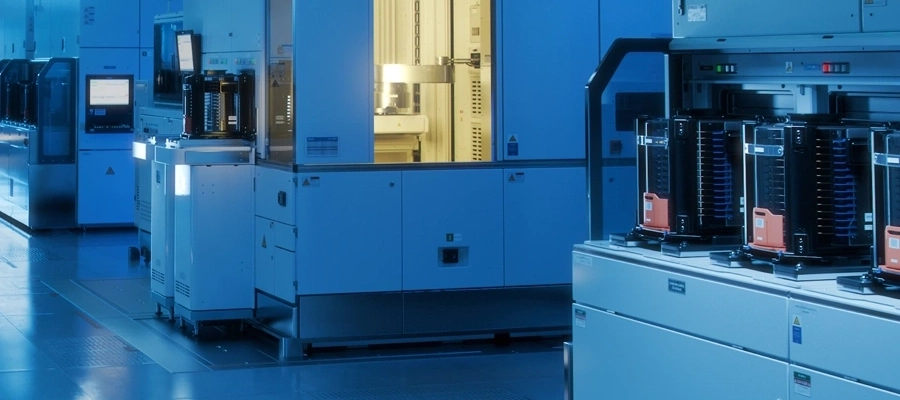

For Industry’s Most Demanding SubFab Applications

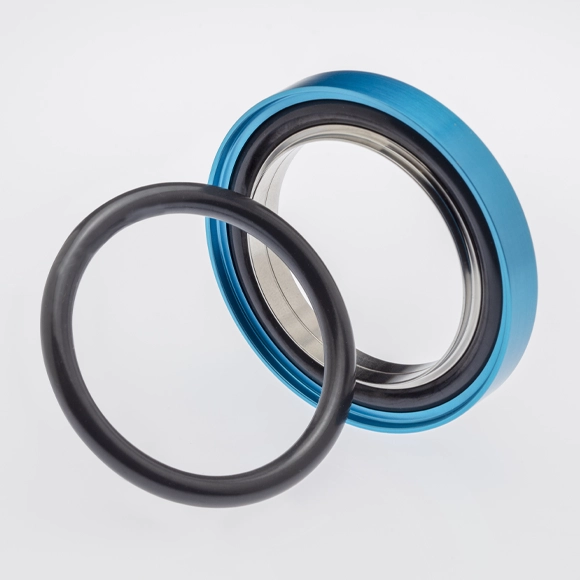

Semiconductor SubFab operators know downtime and maintenance are costly – that’s why Fusion® F07 is designed to meet and exceed the aggressive demands of SubFab environments. Currently available as individual O-rings or assemblies for vacuum system lines, this new FKM elastomer is built to handle oxygen- and fluorine-based chemistries common in etch and CVD processes.

Fusion® F07 retains its form and function at temperatures up to 355°F (180°C) and boasts a minimum expected lifetime of six months. When equipment failure is not an option, choose Greene Tweed.

Features and Benefits

- Better plasma performance in oxygen- and fluorine-based chemistries than standard FKM

- Better total cost of ownership where application does not call for an FFKM compound

- Minimum expected lifetime of six months

- Form fit replaceable with other industry standard (KF/ISO) seals

- Blue outer ring allows for easier identification upon installation and replacement

- O-rings available individually or as an assembly

Get In Touch!

Contact us to learn more about how Fusion® F07 can work in your SubFab applications.

Industries & Applications

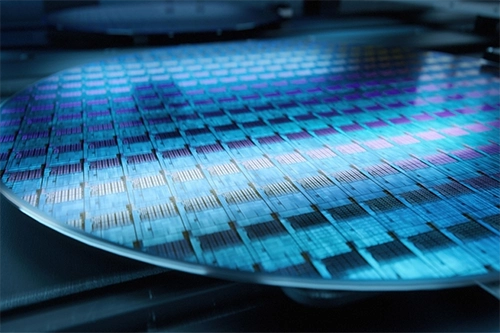

A high-performance FKM elastomer made for SubFab

Fusion® F07 products are designed for use across a wide range of semiconductor applications. No matter how demanding the environment, our team works with you to determine the right solution for the job.

Applications include:

- ISO-KF vacuum fittings, including typical sizes: KF16, KF25, KF40, KF50, ISO63, ISO80, ISO100, ISO160, and ISO200

- Heated and non-heated lines in vacuum systems

Reliable Performance

Fusion® F07 is a proven, reliable engineered component solution. It is available in the form of individual O-rings and assemblies.

Enhanced Purity and Plasma Performance