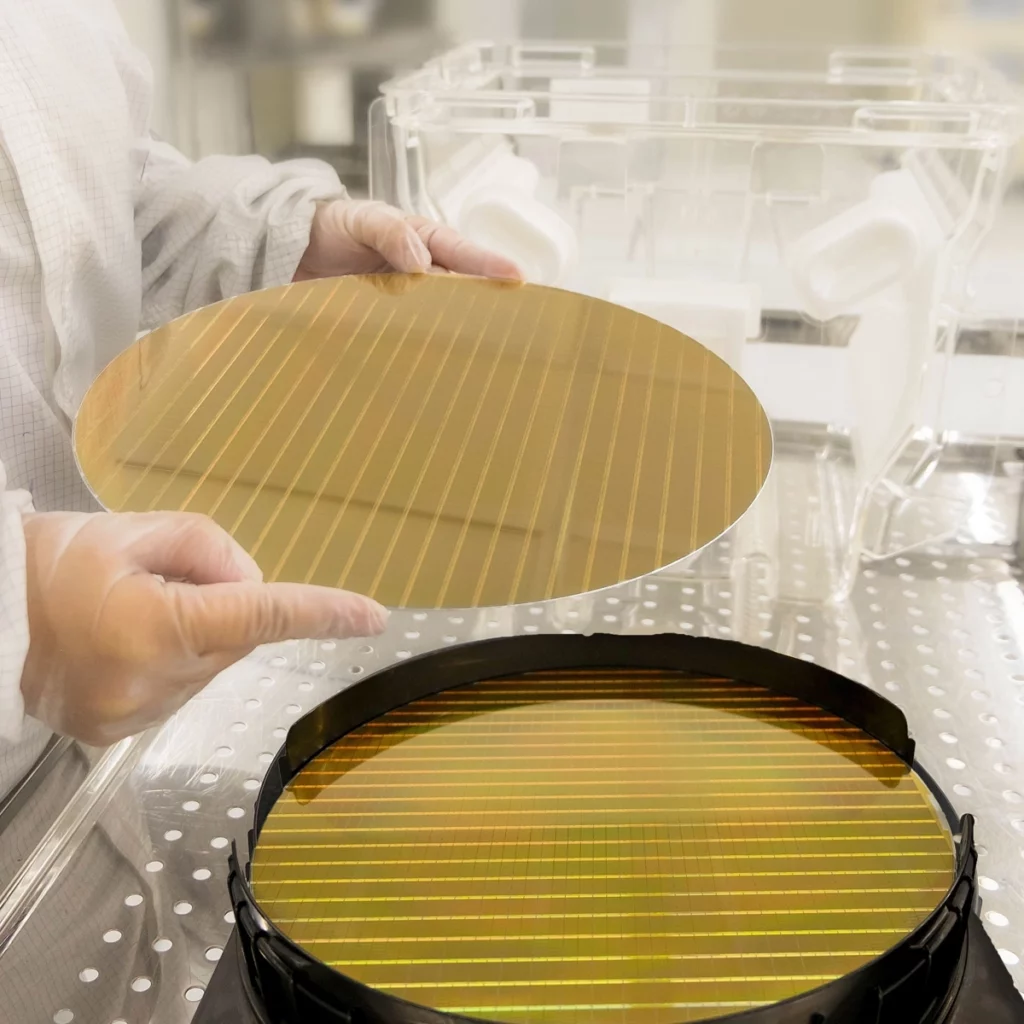

Dynamic Product Applications

High Strength, High Purity

Greene Tweed engineered components are built to handle extreme temperatures and corrosive environments. Applications include:

- Outer chuck rings

- Inner bases

- Chuck pins

- Chuck heads

- Clamp chucks

- Screws

- Cover nozzles

- Bolts

- Guide pins

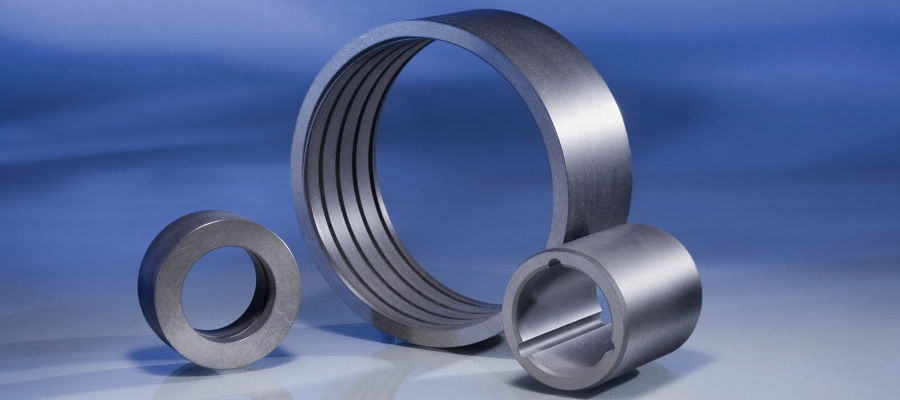

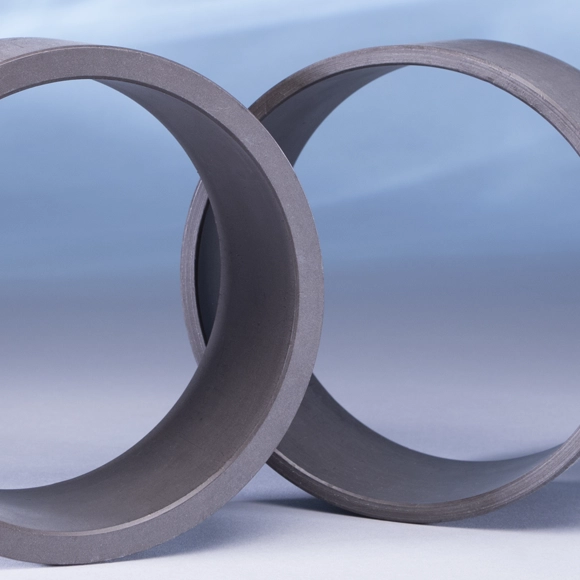

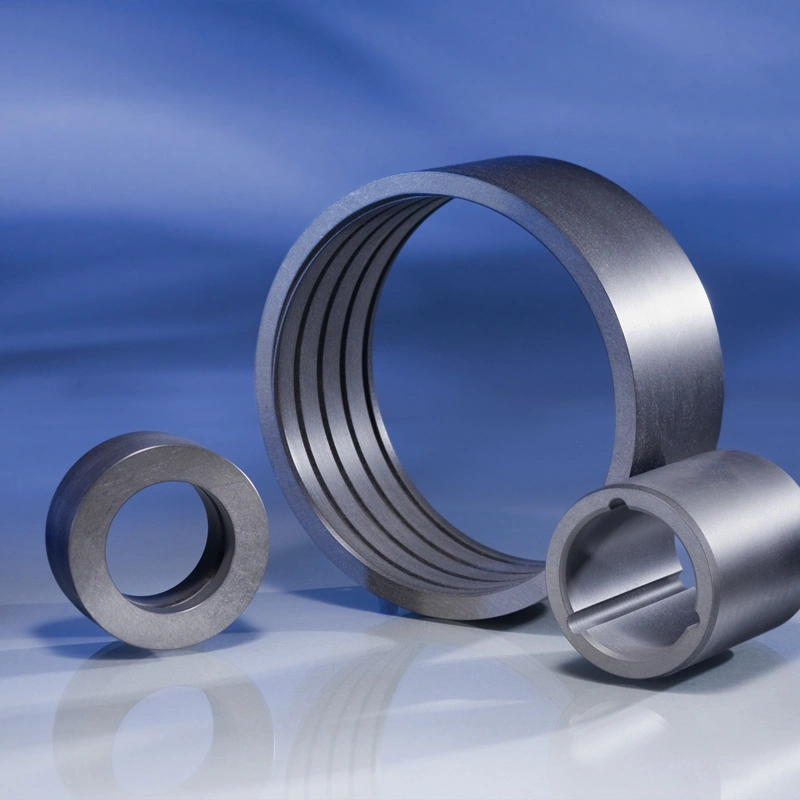

Centrifugal Components

Greene Tweed solutions reinforce rotating and stationary surfaces with wear rings, bearings, bushings, and thrust bearings designed to restrict flow.

Field-tested Innovation

Safety and efficiency drive innovation in Greene Tweed thermoplastic composite wear parts. Our application engineers understand the industry standards for refineries, chemical plants, and power generation plants.

Your Next Engineered Components Solution

When it can’t fail, contact Greene Tweed.