Industries - Hydrogen Power

Ready for the Future of Clean Energy

Solutions for When it Can’t Fail

As constant innovators, Greene Tweed stays ahead of the game when it comes to securing the future of the hydrogen economy. Our experts develop clean, safe, and reliable products for applications that are too important to fail.

Explore our Energy:

With over 200 engineers working across three continents, Greene Tweed has the expertise and knowledge to support your hydrogen power applications.

The hydrogen economy is here. Greene Tweed experts are ready to bring new solutions to the valves, compressors, electrolysers, fuel cells, and other equipment for hydrogen’s most critical applications.

With a proven portfolio of sealing solutions designed to take on extreme environments, Greene Tweed materials and products keep emissions low and purity high across a range of temperatures, pressures, and chemicals.

Expert Application Engineering

Take On Extreme Conditions

Hydrogen Valves

Greene Tweed understands it is necessary to keep fugitive emissions low to stay safe when working with hydrogen – that’s why our solutions are built from the strongest materials for secure hydrogen processing:

Stem seals

- Avalon® 56 V-stacks made from low permeability, high purity modified PTFE that can reduce leakage at low temperature (-40°C / -40°F) and high pressure (700 bar / 10,152 psi)

RGD resistant seals

- Fusion® 938 O-rings made from high performance FKM with exceptional resistance to H2 exposure

- MSE® spring energized lip seals for extreme temperatures (from cryogenic to 288°C / 550°F) and pressures (up to 2 070 bar / 30,000 psi)

Low temperature seals

- Fusion® 665 O-rings made from high performance FKM for low temperature services (-57°C / -71°F)

Valve seats

- Arlon® 3000XT cross-linked PEEK with exceptional creep resistance (25x better than PEEK)

Meet Supply Demands

Hydrogen Compressors

For the safe transport of hydrogen, Greene Tweed engineers recommend the following compressor solutions:

Reciprocating Compressors

RGD Resistant Seals

- Fusion® 938 O-rings made from high performance FKM with exceptional resistance to H2 exposure

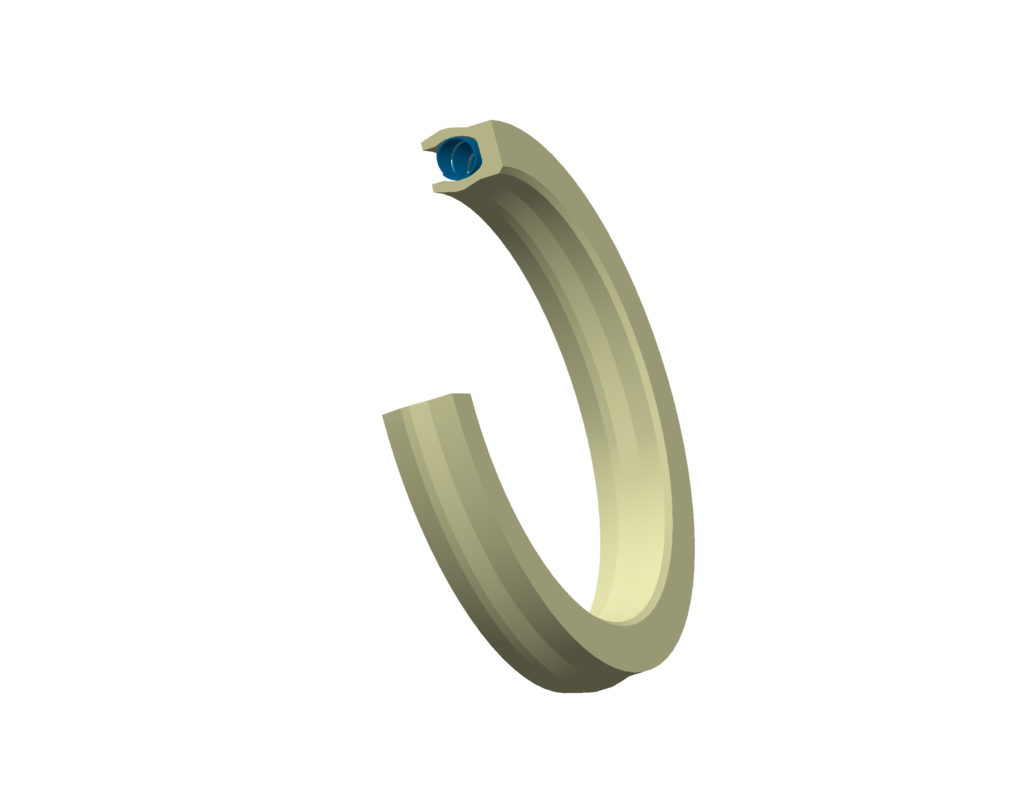

- GT® Ring for extreme pressures (up to 900 bar / 13,050 psi) and RGD resistance

- MSE® spring energized lip seals for extreme temperatures (from cryogenic to 288°C / 550°F) and pressures (up to 2 070 bar / 30,000 psi)

Piston rings, Rider bands, & Valve plates

- Arlon® 3000XT cross-linked PEEK with improved wear & friction properties at high temperatures

Centrifugal Compressors

RGD Resistant Seals

- Fusion® 938 O-rings made from high performance FKM with exceptional resistance to H2 exposure with exceptional resistance to H2 exposure

- GT® Ring for extreme pressures (up to 900 bar / 13,050 psi) and RGD resistance

- MSE® spring energized lip seals for extreme temperatures (from cryogenic to 288°C / 550°F) and pressures (up to 2 070 bar / 30,000 psi)

Light-weight Impellers

- Xycomp® carbon-fiber reinforced thermoplastic composite with high strength-to-weight ratio

Labyrinth Seals

- Arlon® 4020 PEEK with customized flexible tooth profile to reduce gaps

Durable Metering Solutions

Hydrogen Instrumentation

Greene Tweed engineers are aware of the problems caused by exposure to leakage issues when metering hydrogen – that’s why our experts constantly innovate new solutions to keep your instruments durable and safe:

RGD resistant seals

- Fusion® 938 O-rings made from high performance FKM with exceptional resistance to H2 exposure

- GT® Ring for extreme pressures (up to 900 bar / 13,050 psi) and RGD resistance

- MSE® spring energized lip seals for extreme temperatures (from cryogenic to 288°C / 550°F) and pressures (up to 2 070 bar / 30,000 psi)

Low Temperature Seals

- Fusion® 665 O-rings made from high performance FKM for low temperature services (-57°C / -71°F)

Drive the Hydrogen Economy

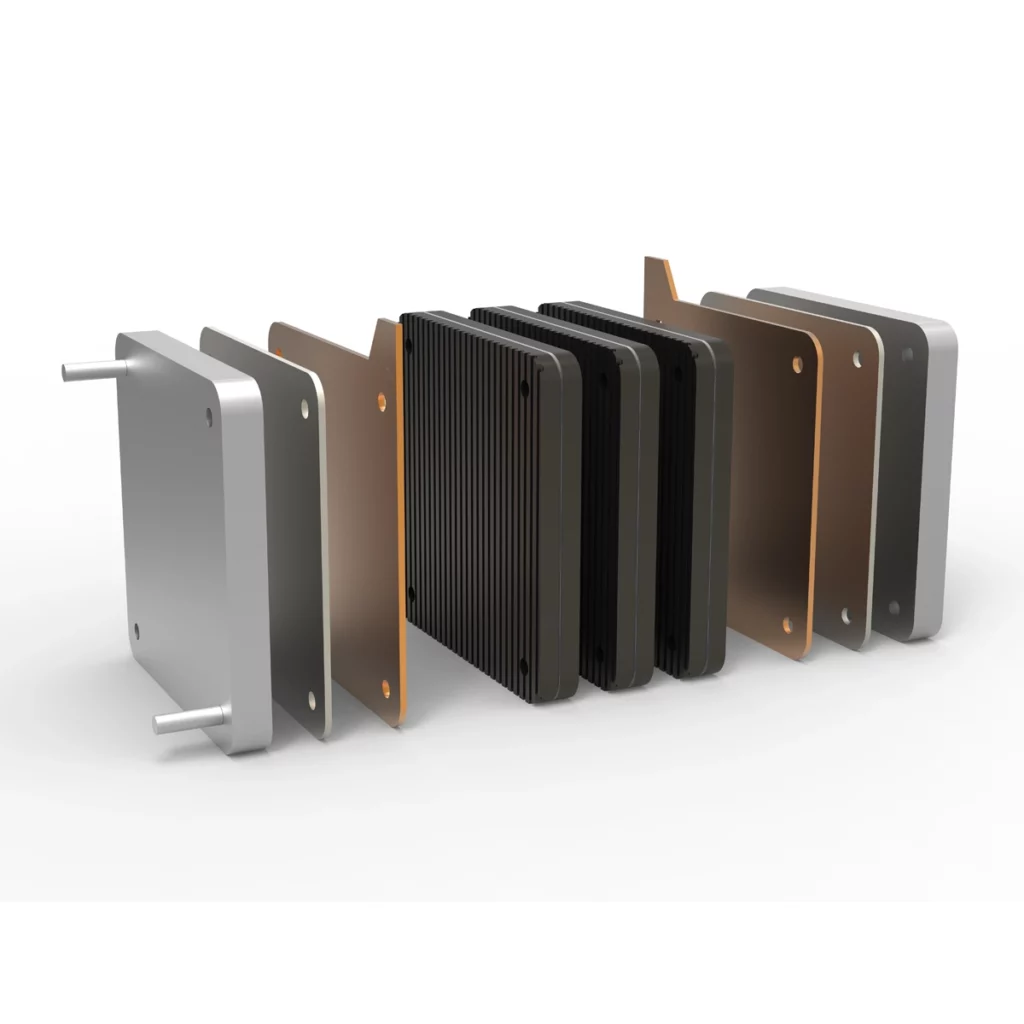

Electrolysers and Fuel Cells

Greene Tweed solutions have been designed to handle the increase in temperatures and pressures required to develop the next generation of fuel cells and electrolysers Arlon 3000XT®

- Improved chemical resistance over standard PEEK

- Retaining mechanical properties of standard PEEK at higher temperature

- Better resistance to thermal cycling>

- Available as structural rings, cell frames for electrolysers, and compression end plates or MEA sub-gasket films for fuel cells

- Bipolar plate gaskets made from high performance FKM for low temperature services (-57°C / -71°F)

Industry-Proven Products

When Downtime isn’t an Option

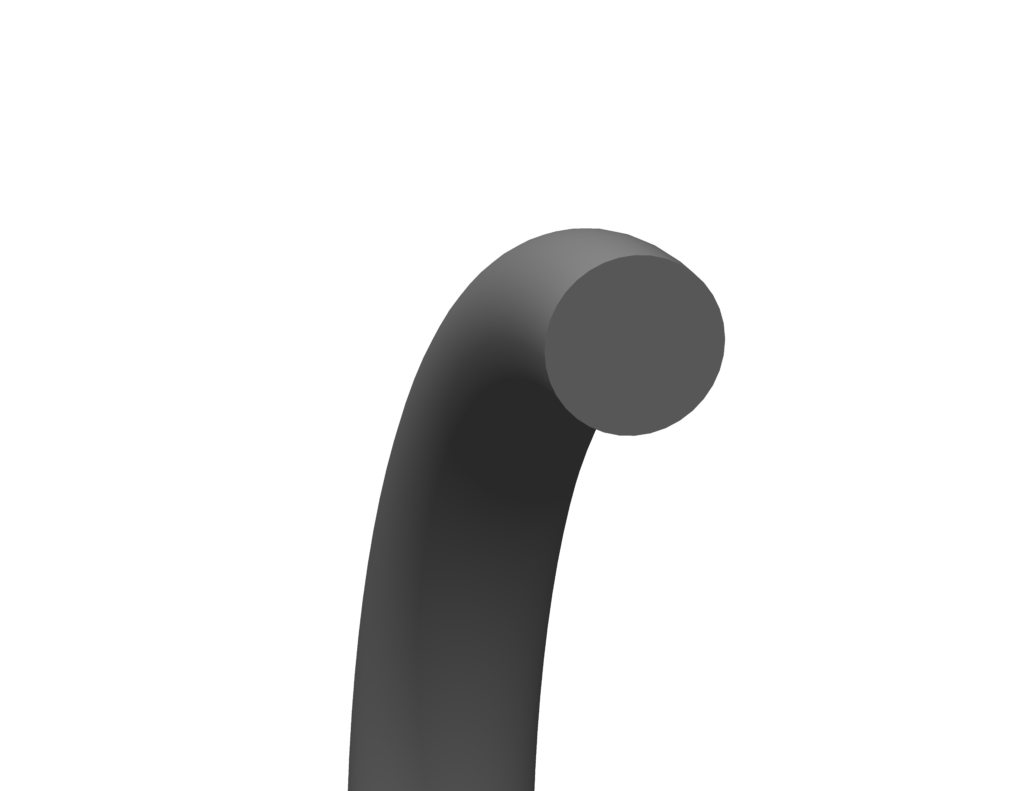

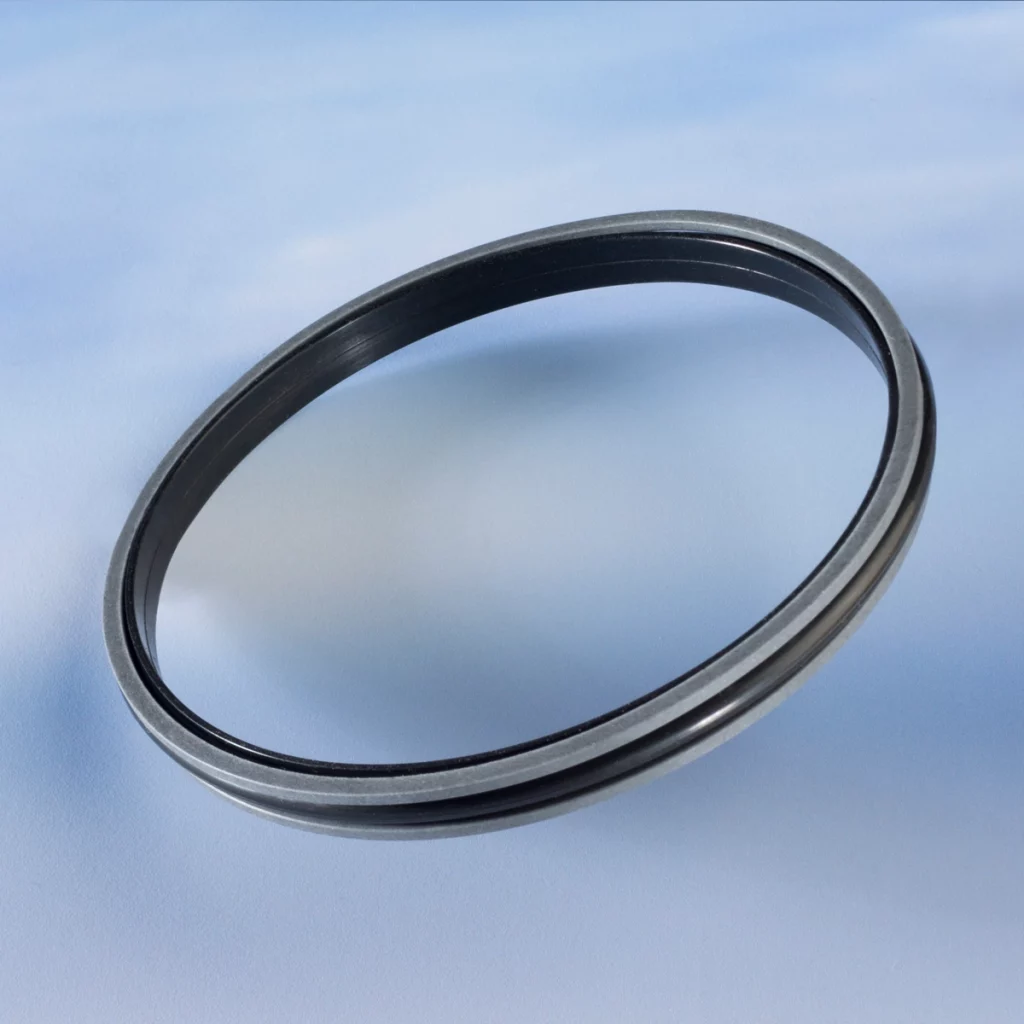

The most common type of elastomer seal, Greene Tweed’s O-rings provide cost-effective, flexible sealing solutions for industry’s harshest conditions. The O-ring can be used either as a seal itself or as the energizing element in PTFE, cap-type seals.

For additional backup rings, Greene Tweed’s engineers will work with you to develop a custom configuration suited to your needs.

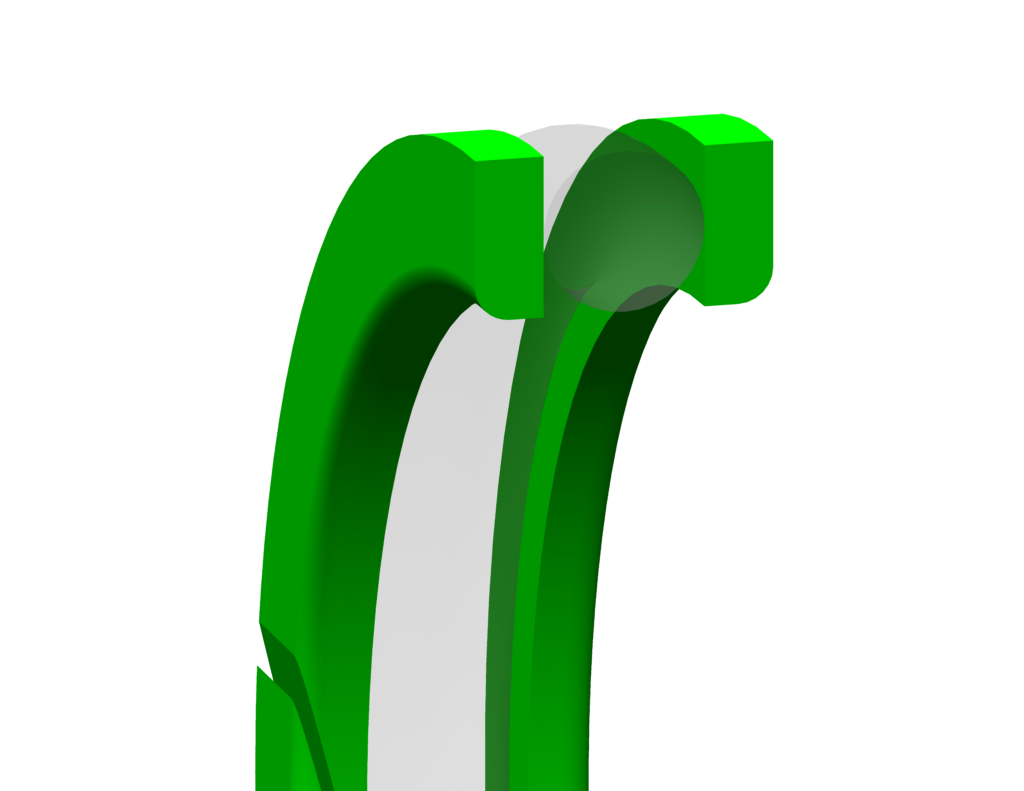

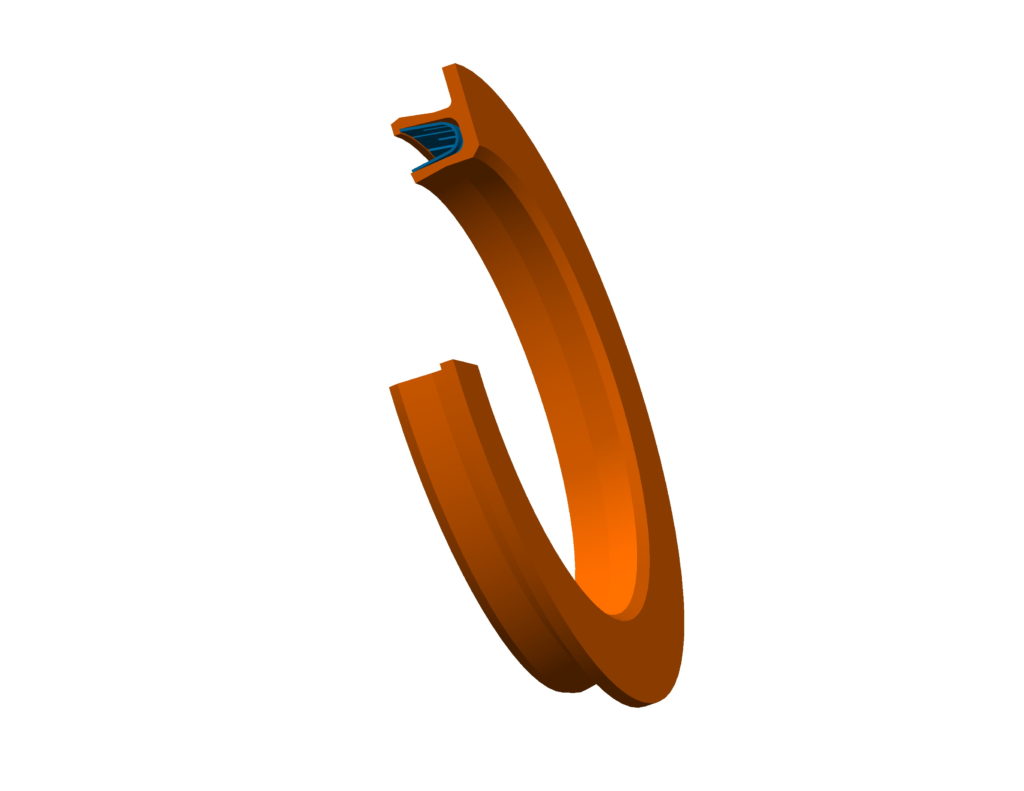

Advanced T-Seals for Demanding Applications

Greene Tweed offers a wide range of standard and custom engineered T-seals for easier assembly, low leakage, and longer service life.

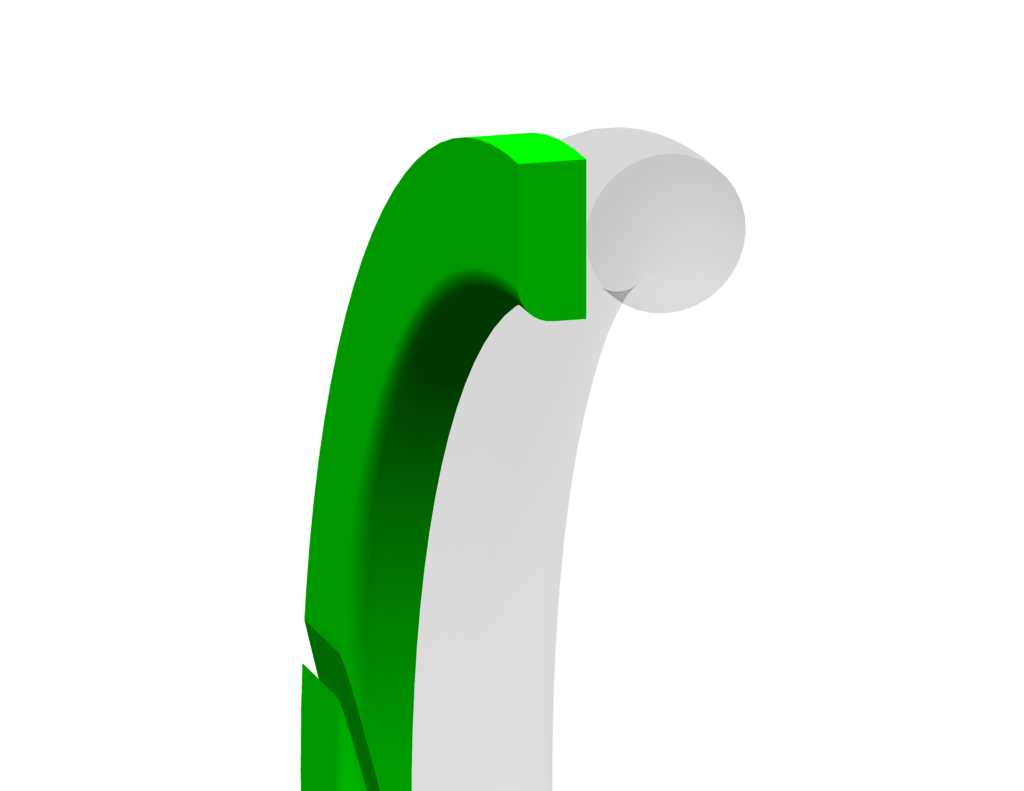

Versatile Sealing and Scraping for Demanding Environments

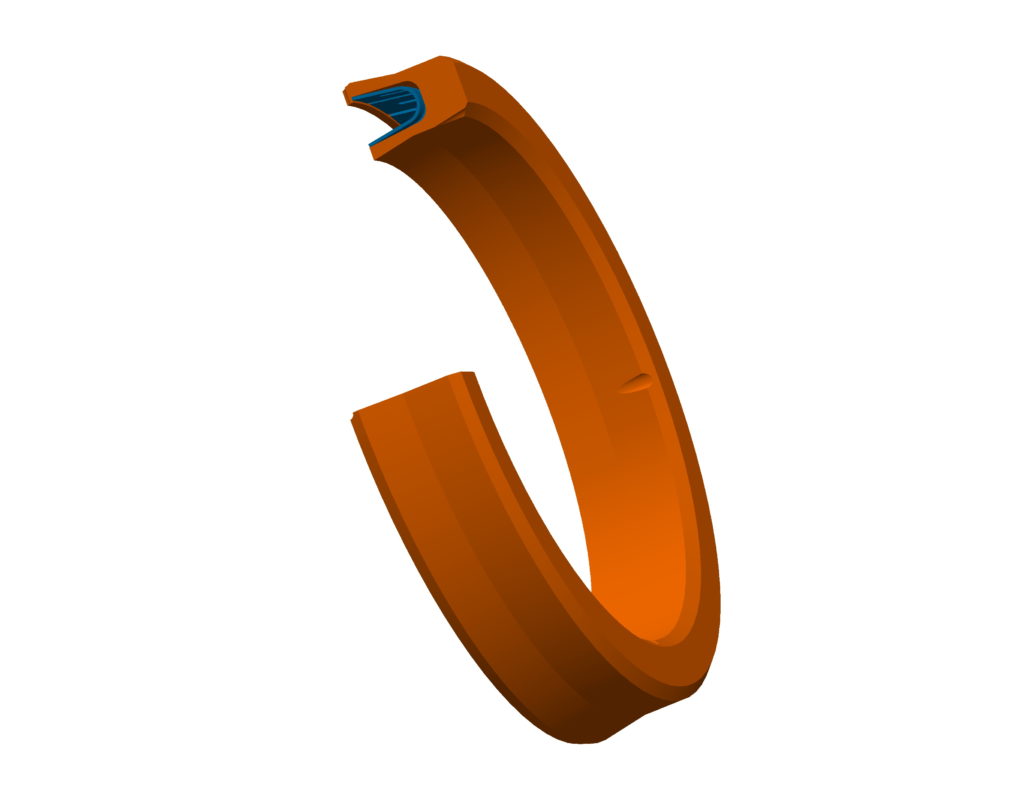

MSE® metal spring energized seals are custom designed with a dual-lip body for superior performance in the most demanding conditions.

- High pressure or low pressure requirements, from vacuum up to 30,000 psi (2,070 bar) plus

- Large temperature variation, Cryogenic to 550°F (288°C)

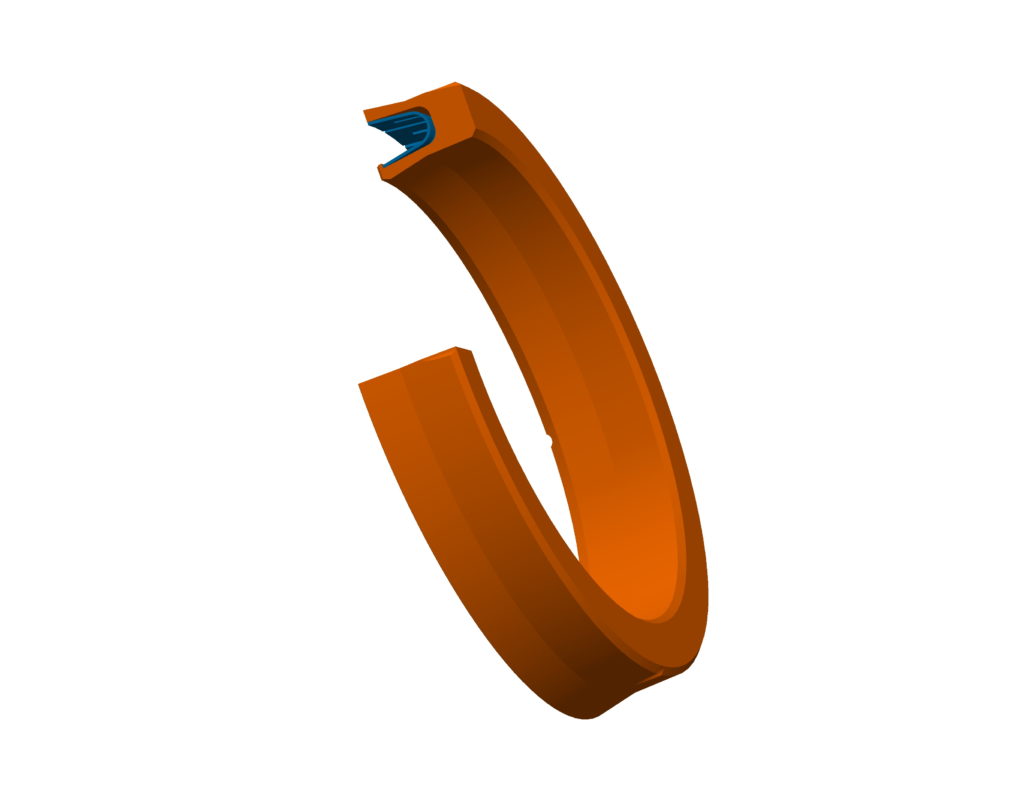

Versatile Sealing and Scraping for Demanding Environments

For applications requiring specialized elastomeric and/or thermoplastic properties, Greene Tweed’s V-rings, adapters, and seal stacks deliver proven performance when exposed to extreme temperatures, corrosive chemicals, and other damaging contaminants.