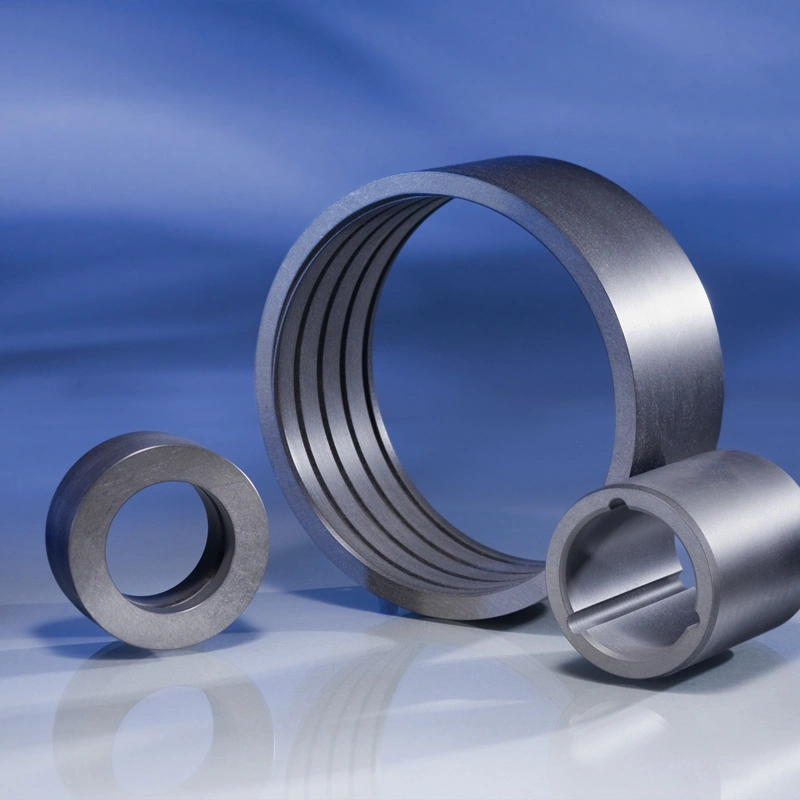

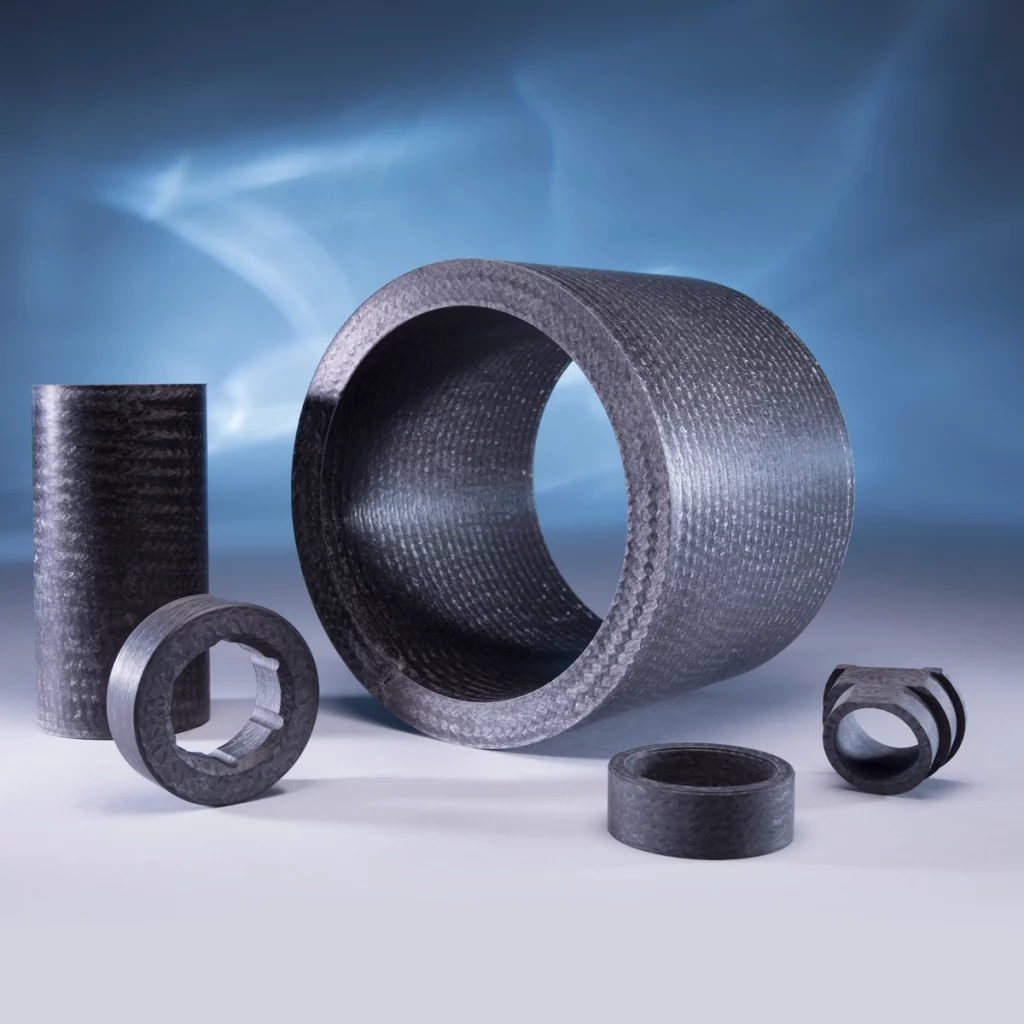

Product Details

Reduced Wear and Friction

Looking to improve uptime and extend the service life of your pump wear components? Greene Tweed’s WR® (Wear Resistant) line reduces wear and friction while delivering superior non-galling, non-seizing performance. With longer dry runs and exceptional chemical resistance, WR® materials improve the stability and overall efficiency of your operations.

For a detailed look at WR® capabilities, explore our Thermoplastic Composite Chemical Compatibility guide.

Features and Benefits

- Strong chemical resistance

- Non-galling/non-seizing properties

- Low coefficient of friction

- Impact resistance

- Thermal shock resistance

Industries & Applications

Extended Service Life in Every Application

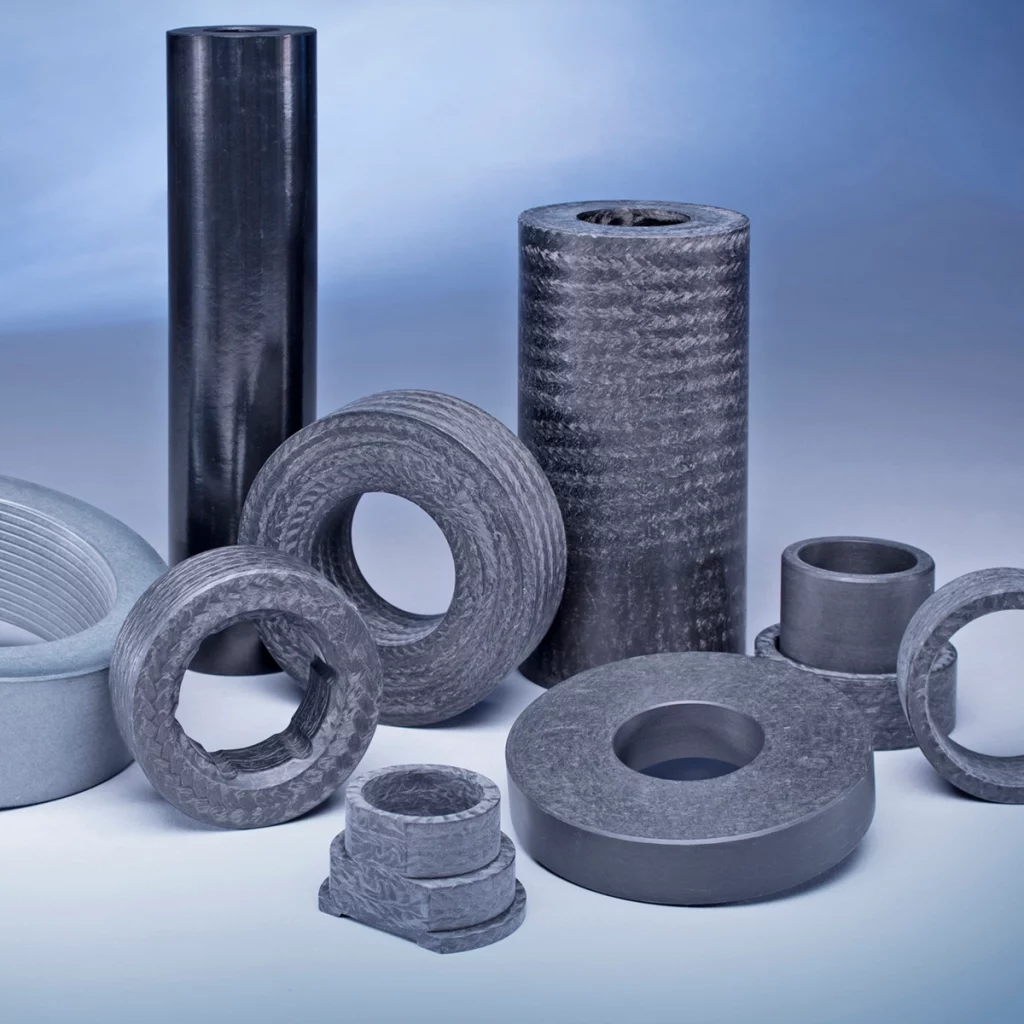

WR® materials are designed to be used across a wide range of applications. No matter how demanding the environment, our team works with you to determine the right solution for the job.

Applications include:

- Wear rings

- Bearings

- Bushings

Reliable Performance

WR® is field-tested for performance and durability in extreme operating conditions. For examples of how Greene Tweed thermoplastic composite solutions can work for you, explore our case studies.