Here’s How Analytical Instruments Makers Extend the Life of Their Seals

This is the second article in a series on Seals for Analytical Instruments. Read Part 1

Precision Glass Works (PGW), one of India’s leading manufacturers of laboratory glassware, was facing a recurring challenge. Educational, forensic, medical, and commercial labs, that use their pressure tubes, work with a diverse range of chemical compounds, such as Dihydrofolic Acid (DHF), Dichloromethane (DCM), Tetrahydrofuran (THF), Amines, and Hydrogen Chloride (HCL). The fluoroelastomer o-rings in PGW’s pressure tubes weren’t compatible with these aggressive chemicals and wouldn’t last more than two testing cycles.

They reached out to Greene Tweed in search of a seal that could withstand the challenges posed by the harsh chemicals and endure multiple testing cycles without faltering. “We recommended Chemraz®605 to extend the lifetime of their o-ring while ensuring the integrity of their products,” said Richard Dilorio Jr., Industry Expansion Manager at Greene Tweed. “Chemraz®605, a high-performing perfluoroelastomer (FFKM), possesses a broad chemical resistance and is ideal for use in a wide variety of media including acids, caustics, aldehydes, esters, ethers, aromatics, hot water, steam, amines, methanol, ketones, TBA, and MTBE.”

PGW sent out their glassware fitted with the Chemraz® 605 seals to the Indian Institute of Education and Research and National Chemical Laboratory. The results showed that Chemraz® 605 could break the two-cycle barrier. Both the labs reported that Chemraz® 605 o-rings could endure the chemical reactions, performed well, and sustained several reaction cycles without any deterioration and continue to do so.

Encouraged by the feedback and performance of the new Chemraz® seals, PGW has now standardized Chemraz® 605 o-rings for their pressure tube equipment.

Chemraz® for Demanding Applications

PGW is not alone. According to Richard, several analytical instrument organizations successfully expanded the lifecycle of their seals in applications such as chromatography systems, hematology analyzers, DNA synthesizers, mass spectrometers, in vitro diagnostic systems, and solenoid valves by switching to Chemraz® FFKM seals, known for their exceptional resistance to aggressive chemicals as well as extreme pressures and temperatures.

He went on to cite several examples. A global leader in control technologies halved its total cost of ownership of the elastomeric seals by using Chemraz® seals in their miniature solenoid valves. A global biotech company eliminated sample contamination, thereby improving performance, and reducing costs by switching to Chemraz® seals in the compression modules of its flash chromatography system. By replacing its silicone seals with Chemraz®605, a global OEM of medical diagnostic equipment was able to develop a chemically inert and robust sealing solution that reduced the risk of sample contamination and system failure in its hematology system.

MSE® Seals That Cut Contamination

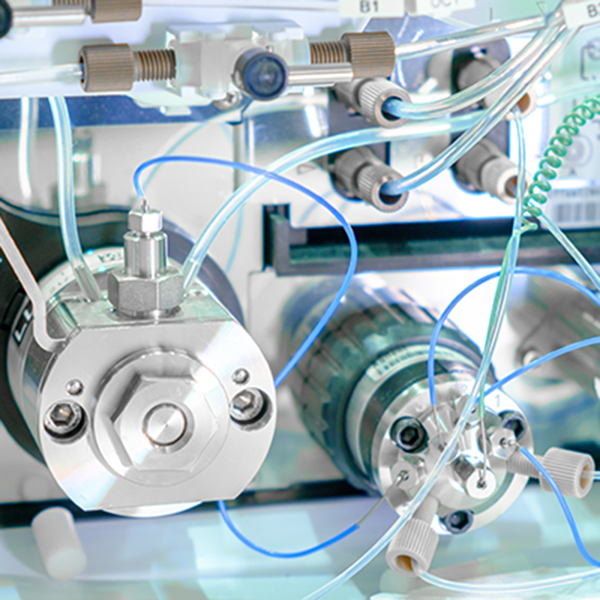

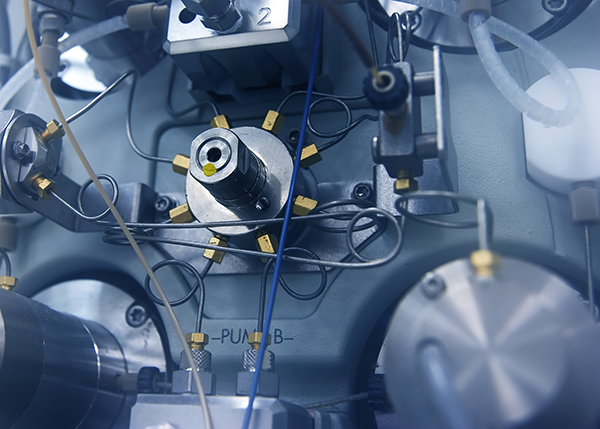

When an HPLC pump OEM found metal ion contamination corrupting HPLC analyses in analytical processes using solvents it turned to Greene Tweed. “Their plunger seals consisted of carbon-filled PTFE and a metal spring. Fluoroelastomer seals, such as FKM, offer adequate durability for water applications, but Chemraz® perfluoroelastomers work best for analyzing solvents,” explained Richard.

Greene Tweed recommended Chemraz-energized MSE® seals to prevent metal ion contamination in solvent analyses and allow the equipment to operate at high pressure of up to 300 kgf/cm2 or 4,267 psi. Already, half of their plunger seals are Chemraz®-energized MSE®s.

Your Challenge

Are your analytical instruments facing a similar challenge? Please reach out to a Greene Tweed representative to explore what our Chemraz® seals and sealing solutions can do for you and your analytical instruments.