How to Choose the Right Seal for Your Analytical Instruments

This is the first article in a series on Seals for Analytical Instruments. Read Part 2

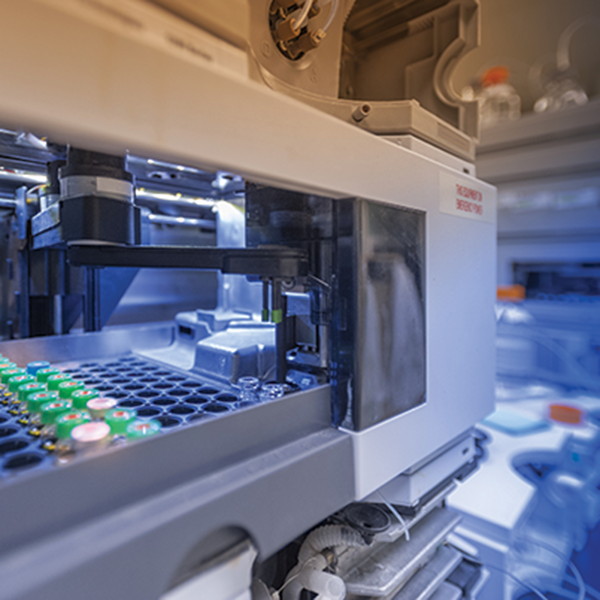

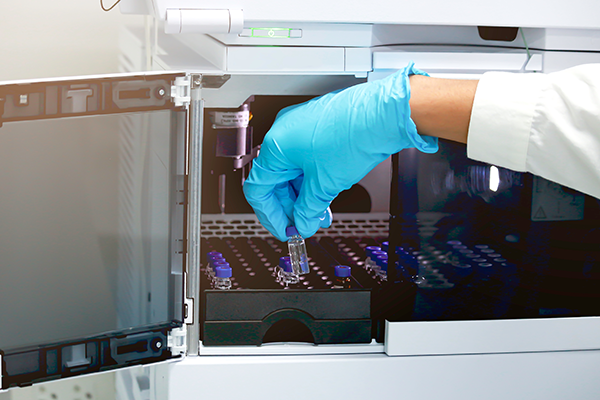

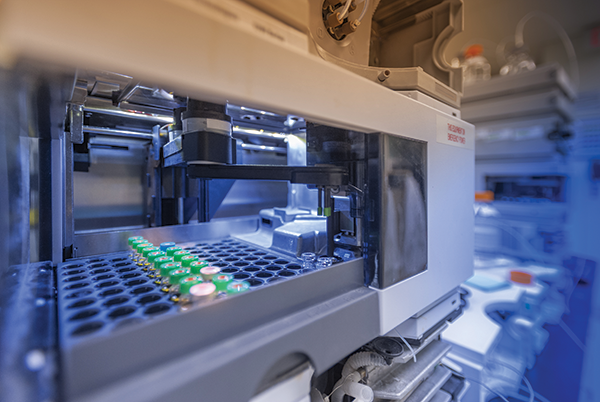

It’s no secret that the demand for more precise and faster diagnosis is driving analytical instrument manufacturers toward harsher and more complex chemicals. However, the same chemicals that enable groundbreaking analyses place increased demand on the materials of construction of components used in these instruments. And the effectiveness of analytical instruments, such as Chromatography Systems, Hematology Analyzers, DNA Synthesizers, Mass Spectrometers, and In Vitro Diagnostic Systems, hinge on their component materials’ ability to handle aggressive chemicals, such as acids, solvents, and reactive gases.

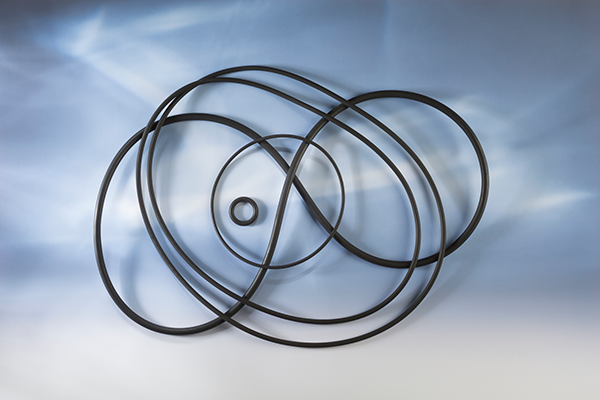

Consider elastomer seals, such as o-rings, that form a crucial barrier between the instruments’ internal components and the chemicals being analyzed. Prolonged exposure to aggressive chemicals, especially under extreme pressure and temperature conditions, can cause seals to degrade, leading to leaks, contamination, unintended downtime, and compromised instrument performance.

A big part of what makes a seal durable, especially in harsh life sciences conditions, is the material that comprises it. “Widely used elastomeric material groups range from those like NBR, HNBR, and EPDM for less extreme applications to more specialized materials like Fusion® FKM, Fluoraz® FEPM, and Chemraz® FFKM for more demanding environments,” said Richard Dilorio Jr., Industry Expansion Manager at Greene Tweed. According to him, analytical instrument makers need to weigh in many factors, such as chemical compatibility and the ability to withstand extreme temperatures and pressures.

Here are a few commonly used elastomers and their characteristics to help users understand which material is best suited for their application.

- EPDM: EPDM elastomers provide good resistance to hot water, steam, and polar solvents such as ethanol, methanol, and ammonia at temperatures up to 149°C (300°F)

- FEPM: If the application needs elastomers that can offer extreme steam resistance, then FEPM such as Fluoraz° is a great choice, especially if fluids such as hydrocarbons and oil are not present.

- FKM: Fluoroelastomers, such as Fusion®, are known for their excellent high temperature, chemical resistance, and good compression set properties. These materials are ideal for applications involving acids, solvents, and reagents.

- FFKM: Premium perfluoroelastomers FFKM materials, such as Chemraz® are well known for their resistance to a broader range of chemicals, including inorganic and organic acids, bases, ketones, esters, aldehydes, alcohols, and fuels. Additionally, Chemraz® offers remarkable high-temperature capability and exceptional resistance to steam above 177 °C/350°F and can be repeatedly sterilized by all conventional methods while ensuring reliable performance. This makes Chemraz® seals and gaskets the prime choice for applications such as high-performance liquid chromatography (HPLC), tissue processing, automated synthesizers, blood analyzers, and other analytical instrumentation applications.

It’s not hard to see why it’s important to match the seal material to your applications’ needs and how an incompatible elastomer material could compromise the integrity of seals and in turn analytical instruments’ reliability, lifespan, and accuracy.