Hydrogen: A Déjà Vu Moment for Arlon 3000XT®

The key to new challenges is sometimes hidden in the past. Such is the case with equipment and processes needed to produce, store, and transport hydrogen.

A major hurdle facing those looking to upgrade their equipment or design new equipment is: Lack of polymer materials capable of withstanding the extreme challenges inherent to the hydrogen environment.

Enter Arlon 3000XT®— the world’s first and only cross-linked PEEK-based polymer developed in 2014 by Greene Tweed -- that enabled oil and gas companies to move to deeper reserves with increasingly higher temperatures and pressures. Its enhanced versions are now ready to take on the complex demands of hydrogen technology and future-proof equipment, from fuel cells and electrolyzers to compressors, and valves.

Power of Adaptation

“Industry needs have always driven new material and product development at Greene Tweed. We developed Arlon 3000XT® when existing carbon-filled PEEK would no longer work for the extreme environments of oilfield applications. Challenges raised by hydrogen have now presented us with another opportunity to innovate,” says Technology Manager Kerry Drake, Ph.D.

Consider electrolyzers, for instance. To generate hydrogen from an electrochemical reaction between water and electricity, they need higher operating temperatures to function in an efficient and cost-effective manner. In addition, their components are exposed to aggressive chemicals. Pointing out that existing polymers and composites may fall short of meeting these demands, Kerry asserts that the chemical resistance improvement of Arlon 3000XT® over other high-performance polymers is ideal for components such as frames or gaskets. He explains why: During development, we tested chemical compatibility in strong acids, bases, and other aggressive aqueous chemistries. It showed excellent performance at 200°C/392°F for extended periods. “For electrolyzers, in some cases, uncrosslinked PEEK or filled PEEK doesn’t have acceptable performance. However, we have seen that crosslinking improves chemical resistance and mechanical properties in general, so crosslinked, unfilled PEEK may now be a suitable solution for these environments” he adds.

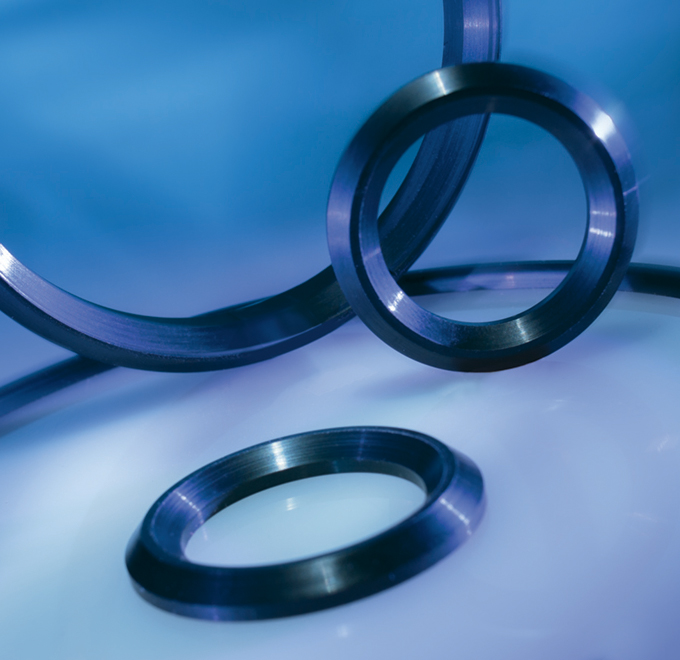

Electrolyzers are not the only equipment that needs a new material compatible with the hydrogen environment. “Fuel cells need material solutions that can withstand challenges, such as material outgassing, chemical compatibility, or degradation of mechanical properties at increased temperatures. Piston rings in compressors and seats in valves are reaching the limit of existing materials to work at very high pressures, and without any lubrication,” says Philippe Allienne, Industry Expansion Manager at Greene Tweed. According to him, Arlon 3000XT® has been able to meet these challenges because Greene Tweed scientists have been continually enhancing the base technology to develop custom compounds for specific hydrogen applications.

One such example is filled grades. “Future hydrogen reciprocating compressors will have to handle more extreme environments and existing materials that used to work, like filled grades of PTFE or PEEK, will not be suitable anymore. We knew that Arlon 3000XT® could provide better performance. However, this material was not developed for wear and friction applications, so we had to optimize it to improve its tribological properties, elaborates Kerry. He goes on to explain with an example, “You can think of it like a dough. It’s up to you, whether you want to make a pizza or a cookie. So, we modified the formulation to make a material suitable for wear application in a reciprocating compressor.”

Validating the Solution

The transformative potential of Arlon 3000XT® is not a mere hypothesis. To ensure that the solutions can withstand hydrogen environments, Greene Tweed tested the material as part of an important research program on material behavior under exposure to hydrogen led by two U.S. national labs. Results from these rigorous high-pressure cyclic exposure tests demonstrated remarkable stability under extreme conditions seen in hydrogen applications, providing tangible evidence of its suitability for hydrogen applications.

Ideal Material for Decarbonization?

The unique properties of Arlon 3000XT® enable this material to push the limits of traditional PEEK grades available. Beside hydrogen, Arlon 3000XT® could also solve challenges inherent to the Carbon Capture industry, for instance. Research shows that the base PEEK polymer could offer superior wetting results compared to metal and other plastics when used as packings for absorber columns*. Using a cross-linked PEEK could increase the high temperature mechanical strength and chemical resistance of PEEK packings, making Arlon 3000XT® an ideal solution to solve the increasing number of material challenges generated by the growing trend of decarbonization.

Crosslinking is a known technique for improvement of chemical resistance and reduction of swelling for polymers. In addition the higher temperature capabilities of Arlon 3000XT® compared to PEEK allow for its use at temperatures close to the boiling points of the CCU CO2BOLs (Binding Organic Liquids), that may range from 230 to 310C.