The Role of Perforating Gun Connectors in Upstream Applications

Perforating systems are a commonly used tool in the Oil & Gas industry to increase well production. These systems are implemented to make holes in the well casing which creates a pathway for flow between the formation and the well bore. The purpose of the perforating gun tool is to deliver explosive shaped charges into the casing and cement in the well.

Reliable Solution

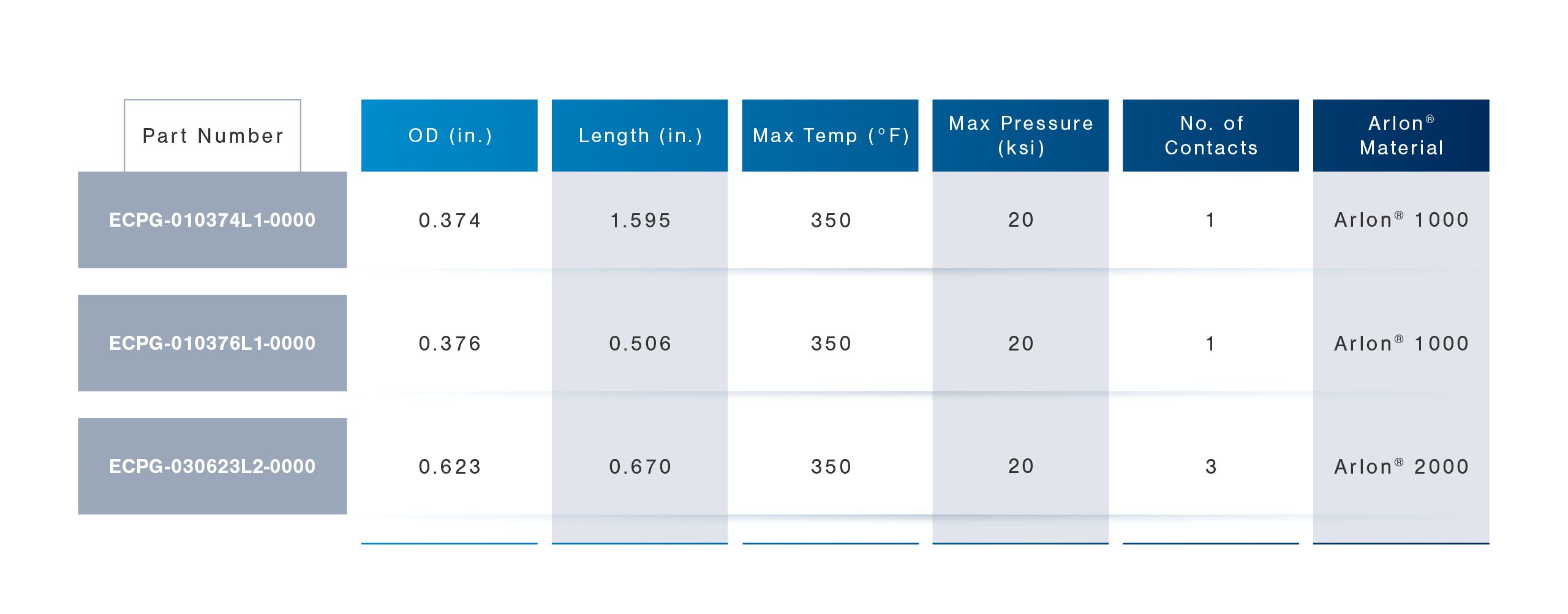

As the completions industry advances, there is a need for faster and more efficient tools to support the fast-paced environment and improve run rates during operation. Within these vital tools, Greene Tweed Seal-Connect offers two electrical connector designs that ensure a reliable connection within the perforating gun tool. Electrical connectors must maintain signal continuity to the igniter and detonator while being exposed to high pressures and temperatures, harsh media, sour gas, extreme shock, and vibration of the explosions. Seal-Connect perforating gun tool connectors can withstand temperatures up to 350°F and pressures up to 20,000 psi.

The single pin bulkhead feedthrough features a retractable contact to improve resistance against shock and vibration.

A three pin feedthrough is also available to provide a more robust design made with Arlon 2000 for higher mechanical strength.

Below are standard offerings for connectors in perforating gun applications. Custom designs are available to fit any application.

Contact Greene Tweed for more information on growing trends and solutions for Upstream applications.