Arlon 3000XT®

Aerospace, Defense, Energy, Industrial, Semiconductor

PRODUCT DESCRIPTION

A Custom-engineered Thermoplastic for Industry’s Most Demanding Applications

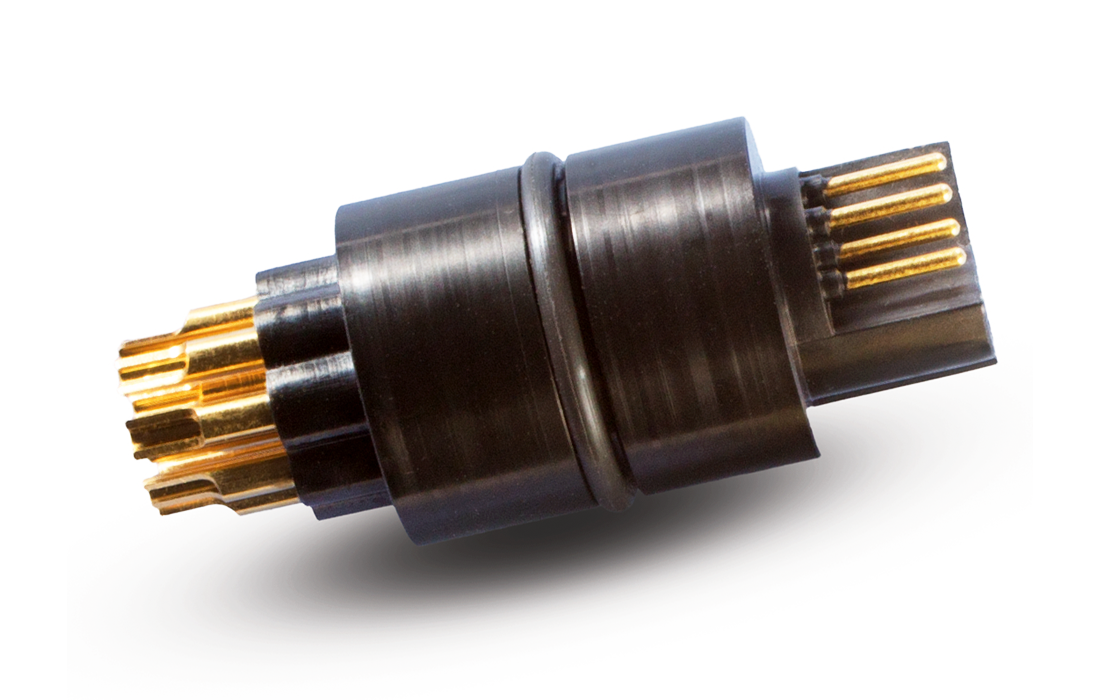

Backed by over 30 years of experience in high-pressure, high-temperature oilfield applications, this crosslinked PEEK thermoplastic delivers proven stability in some of the harshest industrial conditions in the world. And it’s not just for Oil & Gas applications – Arlon 3000XT® can be molded into custom seals, insulators, stock shapes, electrical connectors, and other custom geometries for a wide range of critical applications where equipment failure is not an option.

Features and Benefits

- Superior creep and extrusion resistance at temperatures ranging from 260°C to 300°C (500°F to 572°F)

- Enhanced mechanical and electrical properties for thermal electrical insulating products

- Enhanced high-temperature, high-pressure mechanical performance

- Outperforms traditional material compounds used in back-up rings and other completions tools

- Steam and chemical resistance comparable to PEEK

- Reduced thermoplastic failure at high loads

Industries & Applications:

When it Can’t Fail

Arlon 3000XT® products are designed to be used across a wide range of industries and applications. No matter how demanding the environment, our team works with you to determine the right solution for the job.

Applications include:

- Engines

- Landing gear

- Drilling and evaluations

- Artificial lift

- Electric submersible pumps

- Industrial pumps

Arlon 3000XT® is field-tested for performance and durability in extreme operating conditions.

The world’s first crosslinked PEEK-based polymer, Arlon 3000XT®’s chemical and creep resistance, mechanical strength at high temperatures, and capacity for high-volume manufacturing make it an attractive solution for key components of hydrogen fuel cells and electrolyzers. For an in-depth technical assessment of how Arlon 3000XT® makes equipment dependable, efficient, and safe in hydrogen power applications, download our technical paper.