Energy

Industries - Energy Upstream

Securing the Future of Energy Infrastructure

Innovative Products

Greene Tweed solutions are designed to extend system life and simplify maintenance. Our components protect upstream energy equipment from wear and tear caused by extreme temperature, pressure, and chemical stress.

Years of proven performance in the energy industry

Our experts create products that ensure safety and reliability in oil & gas, petrochemical, and power generation applications.

From design to testing to production, Greene Tweed engineers develop custom solutions tailored to your operations’ exact needs.

Our engineers apply their expertise from prototype testing to validation and production of finished parts. Testing our materials to 37 internationally recognized test methods, making the custom engineered product verified consistent and reliable.

Expert Application Engineering

Superior Designs

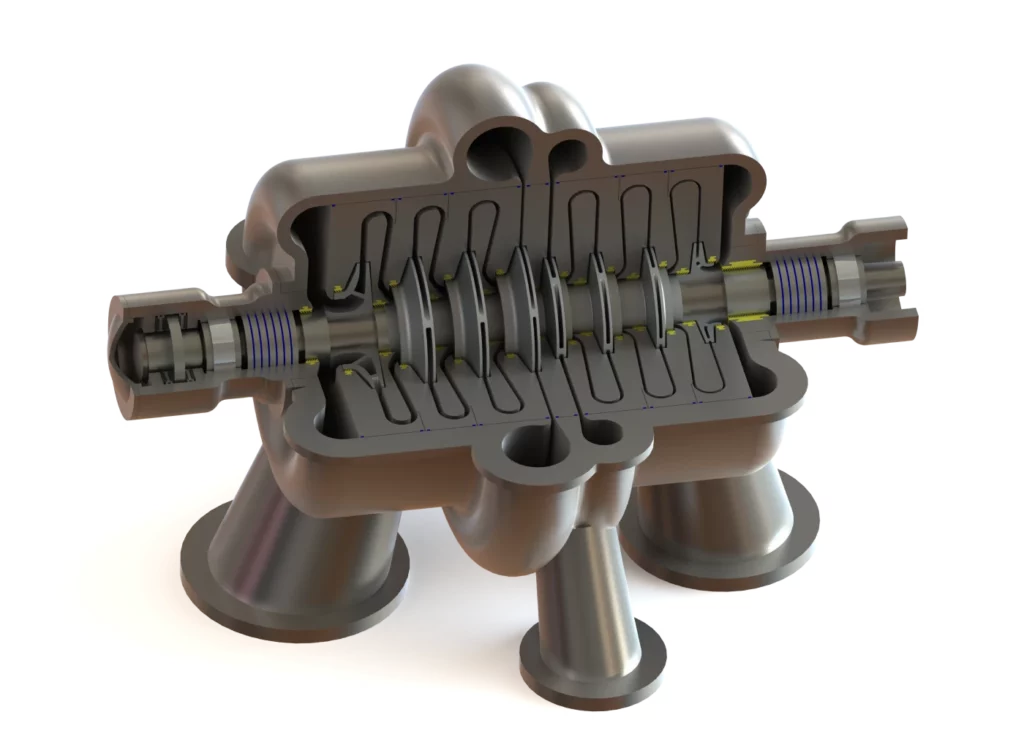

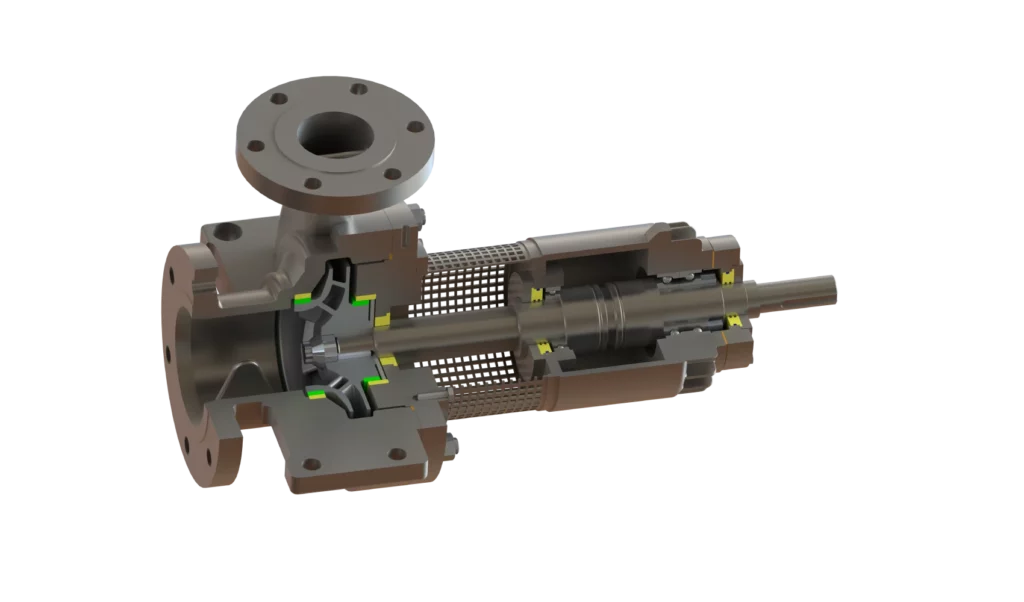

When it comes to rotating equipment like pumps and compressors, downtime can pose huge risks for your workers and your equipment – that’s why our thermoplastic composite wear parts are built for safety and efficiency. Greene Tweed engineers go above and beyond the industry standards for refineries, chemical plants, and power generation plants.

WR® (Wear Resistant) composites cut down wear and friction with non-galling, non-seizing performance.

AR® (Abrasion Resistant) composites reduce downtime for pumps handling media-containing solids.

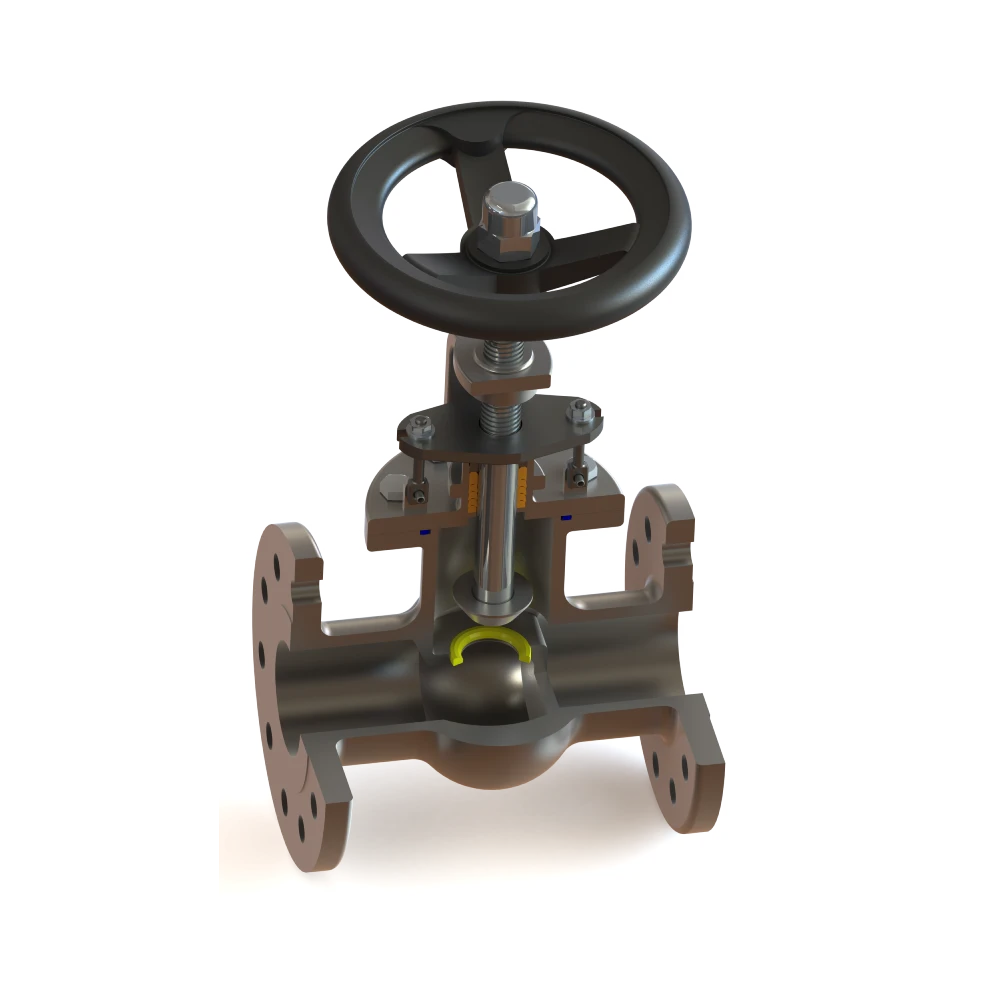

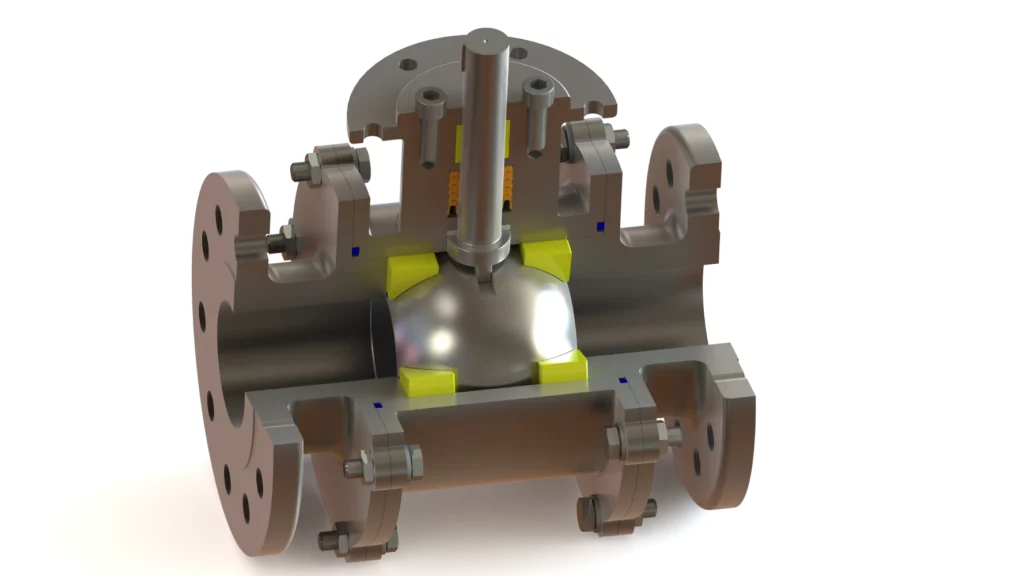

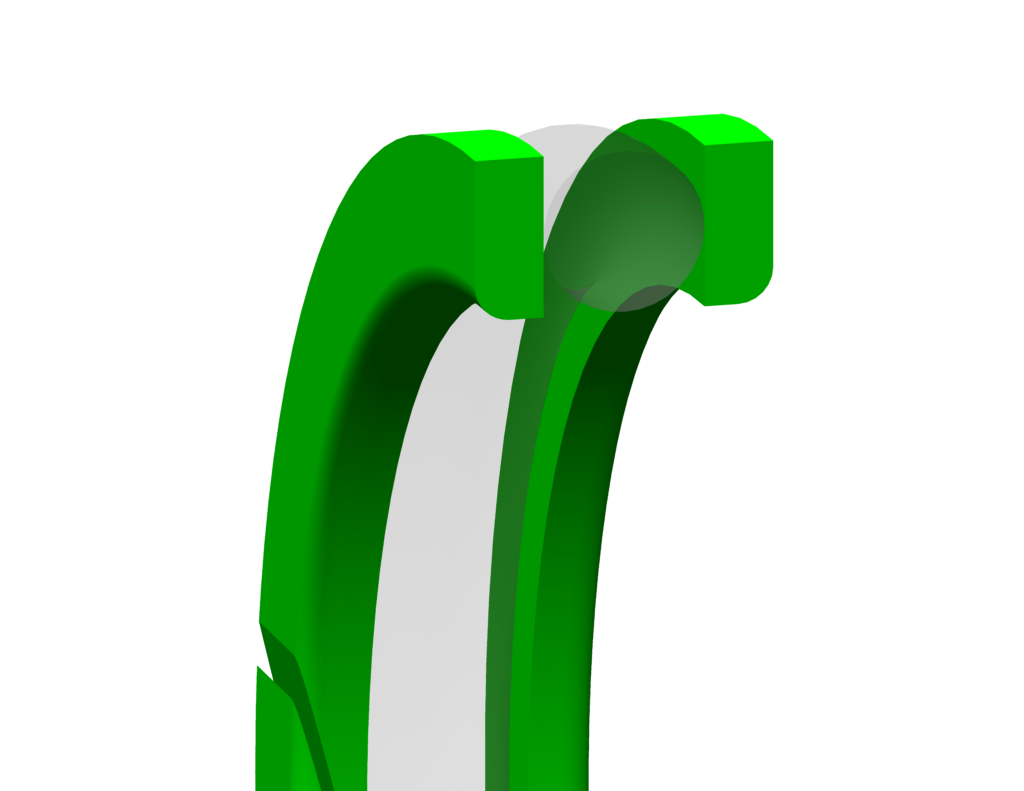

Optimized Valve Sealing

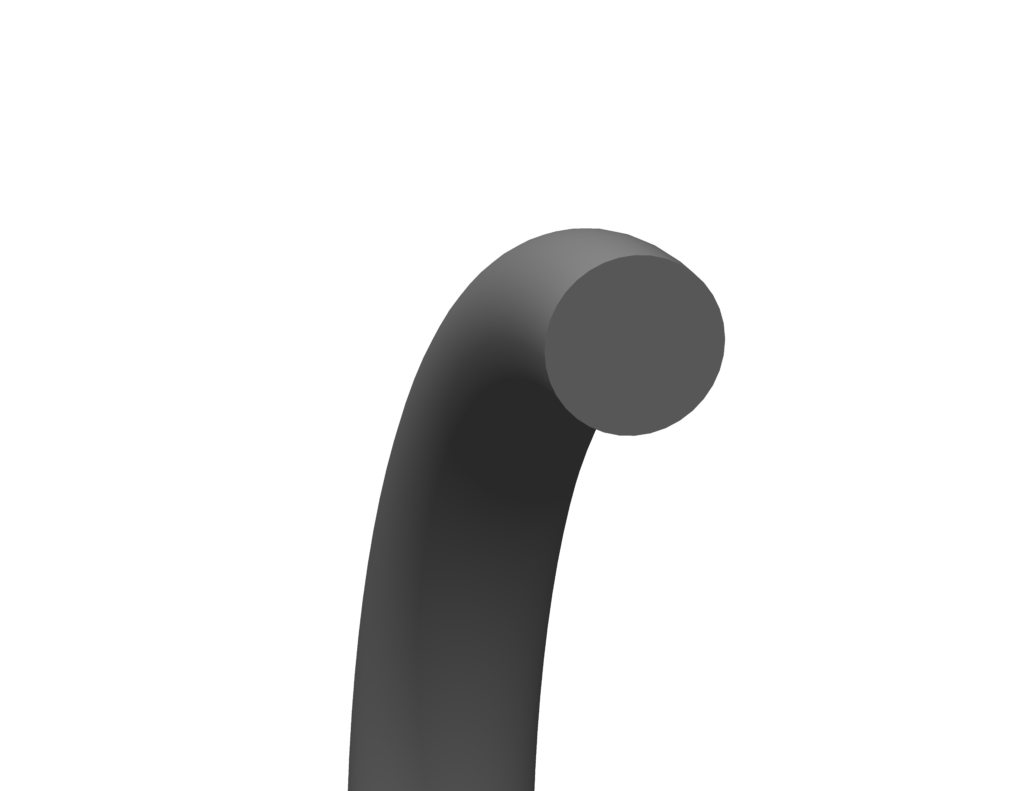

Extend service life, enhance equipment reliability, reduce cost of ownership with Greene Tweed. These advanced sealing solutions for valves are made to withstand the extreme conditions of the oil & gas, petrochemical, and power industries.

Our experts work with you to develop a solution from a wide range of high-performance materials:

- Chemraz® Perfluoroelastomers (FFKM)

- Xyfluor® elastomers

- MSE® lip seals

- Arlon® and Avalon® engineered thermoplastics

Powerful Industry Benefits

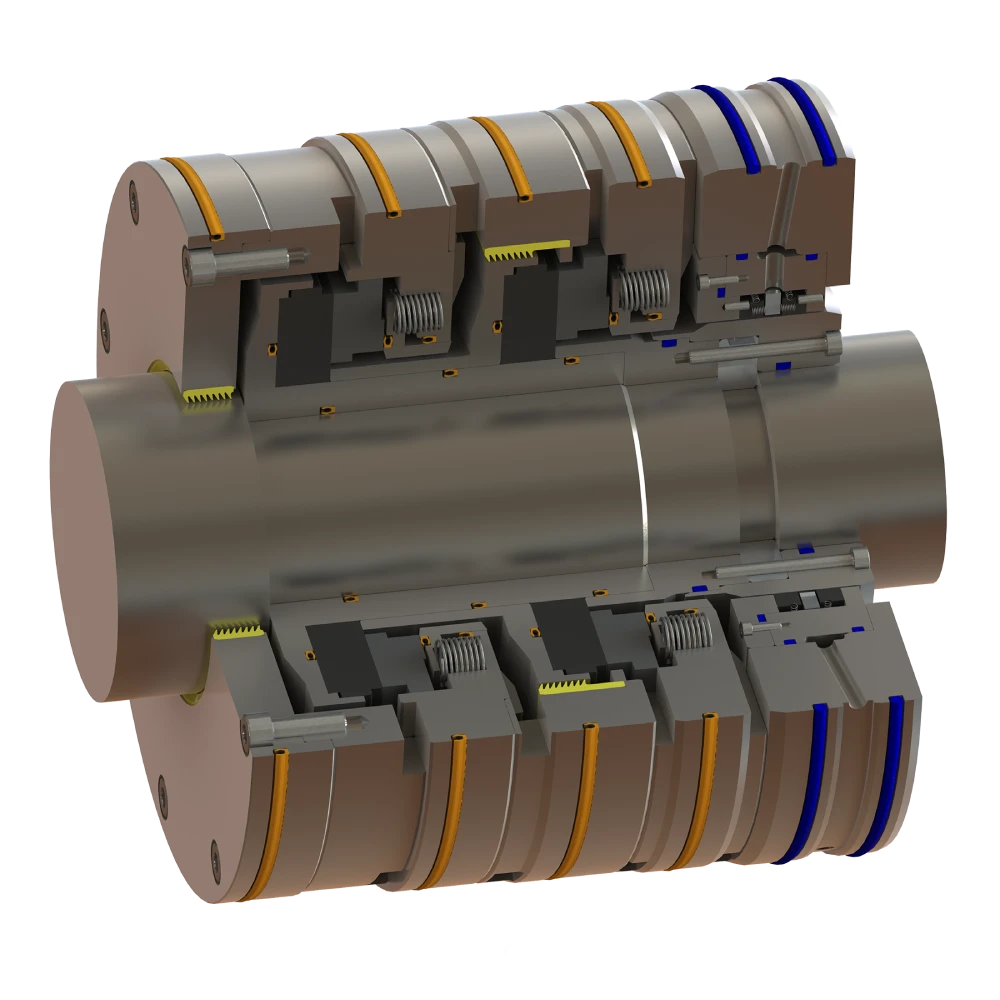

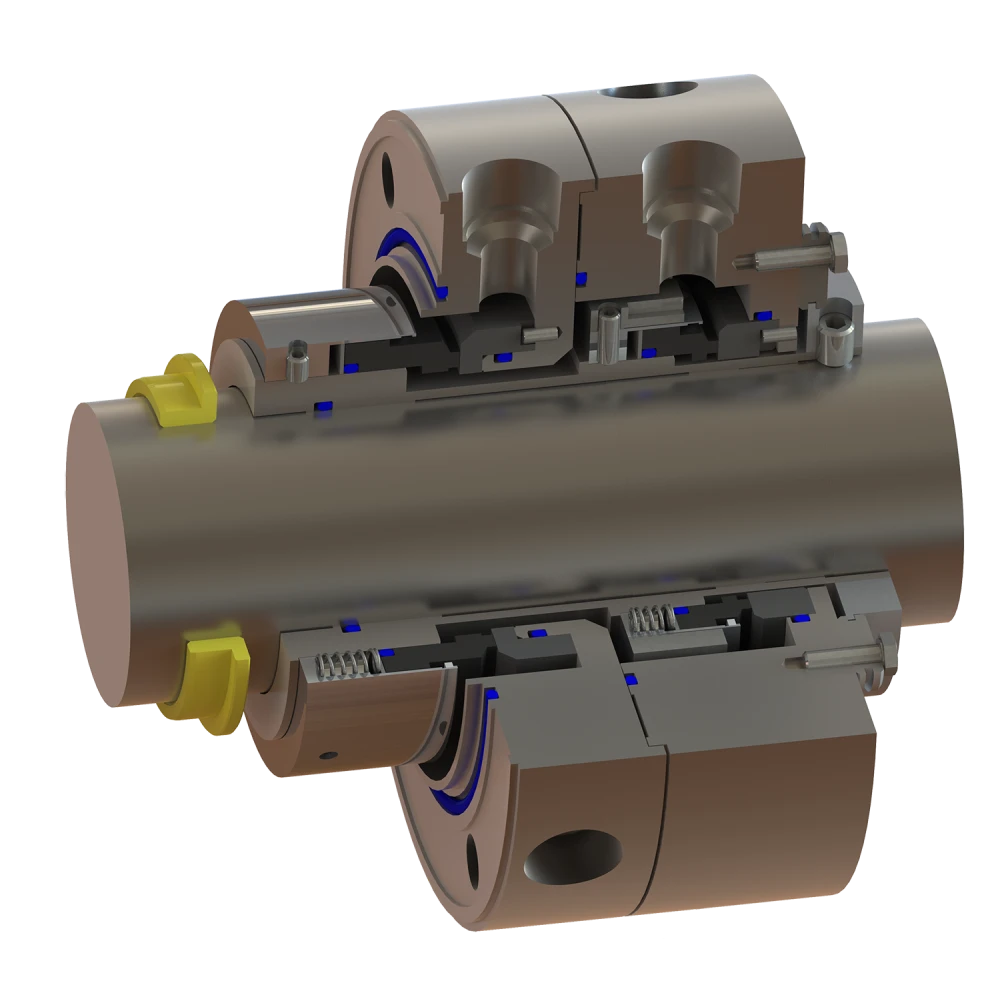

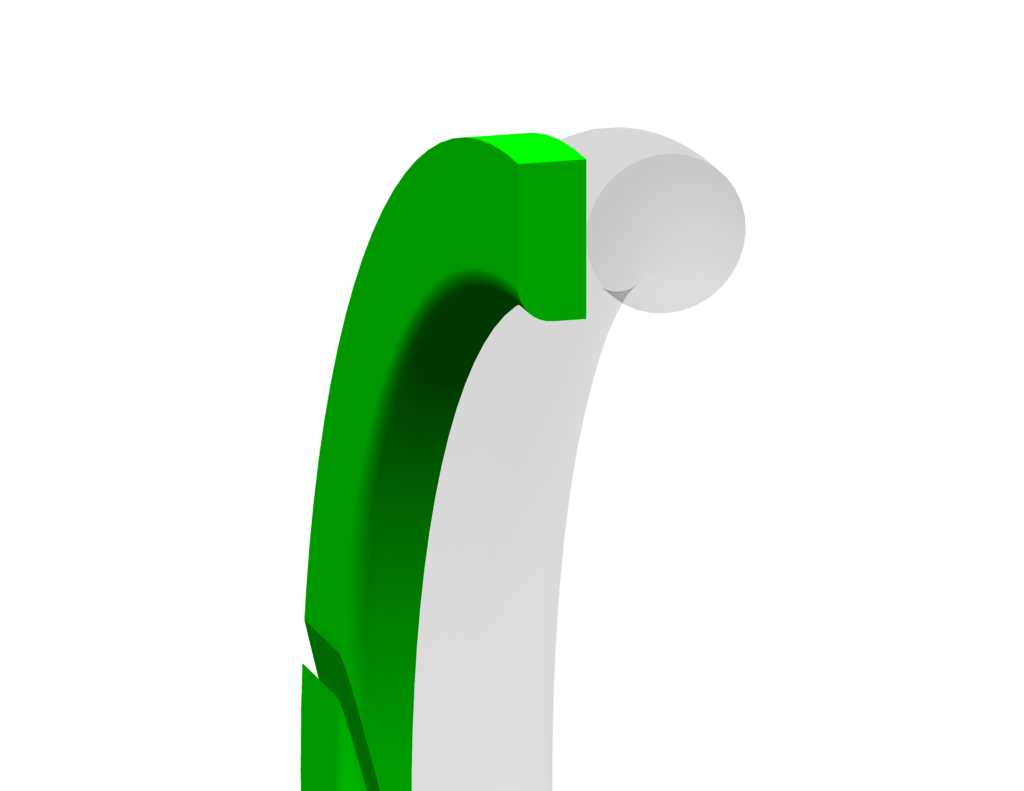

Faulty equipment leads to expensive downtime and safety risks for workers – that’s why Greene Tweed mechanical seals are made to handle the toughest industrial conditions for improved reliability and reduced costs.

Greene Tweed’s secondary seal designs combine elastomeric materials like Chemraz® FFKM and Fusion® FKM and thermoplastics like Avalon® and Arlon®, wiping out process contamination and reducing maintenance time.

Designed to Last

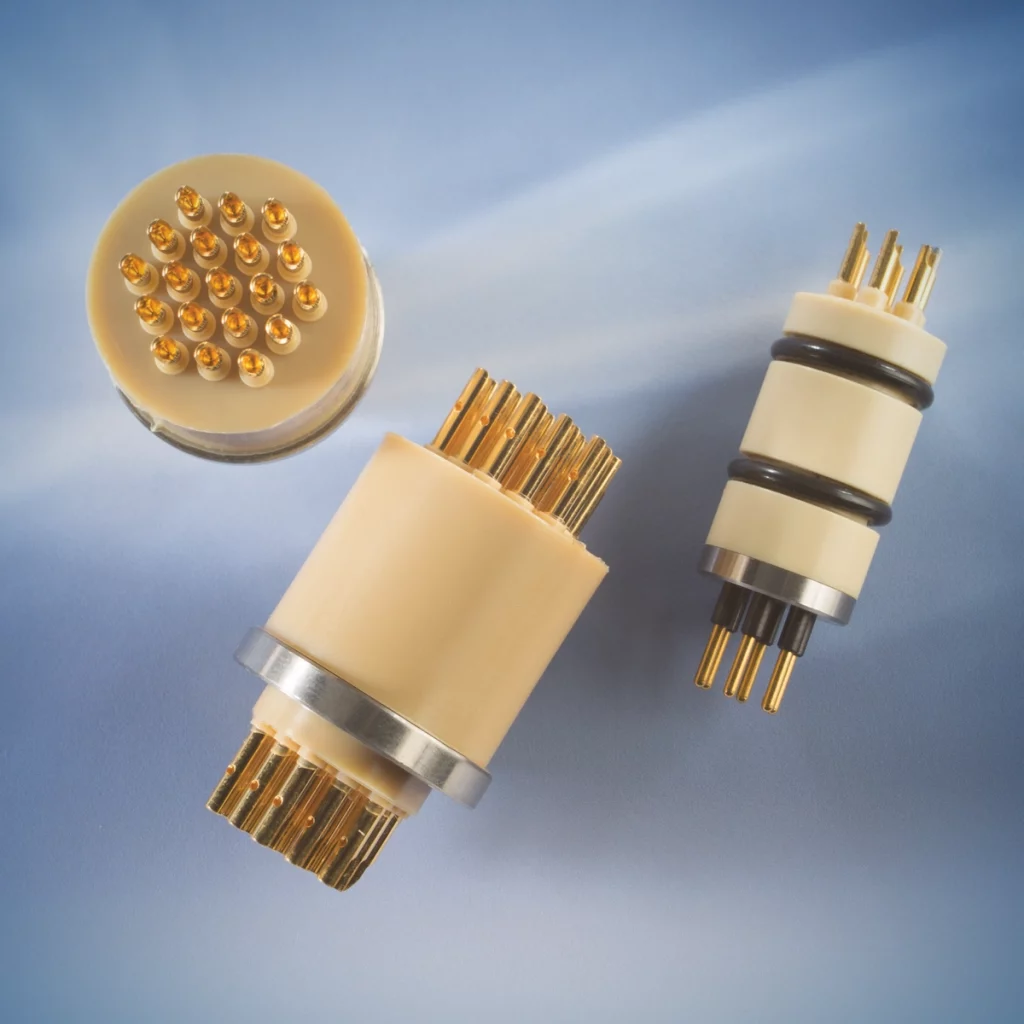

The harsh environment of drilling applications can lead to malfunctions and reduce the service life of your equipment. Greene Tweed drilling and completion tools are built to outlast the competition—even when exposed to extreme temperatures, pressures, and corrosive chemicals.

Seal-Connect® connectors are superior to traditional glass-to-metal technology, ensuring consistent, reliable measurement while drilling (MWD), logging while drilling (LWD), directional drilling, and wireline operations.

Sealing Solutions that Deliver

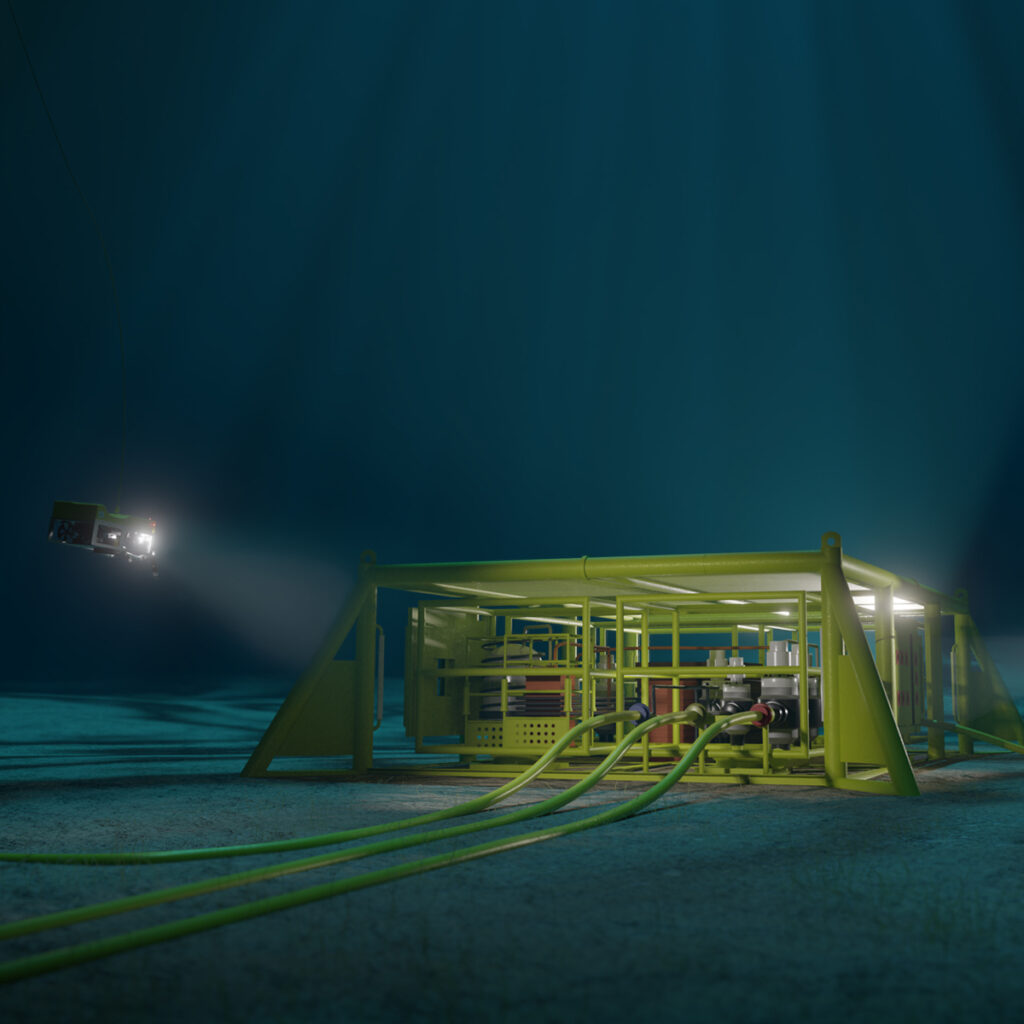

Subsea applications expose your equipment to harsh contaminants, extreme temperatures, and pressure. Greene Tweed components and materials deliver proven performance across a wide range of production equipment including surface and subsea trees, wellheads, liner hangers, SSSVs, subsea risers, and ESPs.