Life Sciences

Industries - Life Sciences

Life Sciences Solutions for When it Can’t Fail

Innovative Products for Critical Applications

Greene Tweed’s advanced materials and engineering expertise deliver industry-leading solutions for pharmaceutical manufacturing, medical devices, analytical instruments, and food & beverage needs.

With over 200 engineers working across three continents, Greene Tweed has the expertise and knowledge to support critical Life Sciences applications.

Greene Tweed collaborates with our customers to design and develop modern solutions for harsh conditions and extreme environments.

Our engineering experts combine application knowledge with best-in-class materials like Chemraz®, Orthtek®, and Avalon® and provide the documentation, testing, and expertise to support your application.

Expert Application Engineering

Proven Pharmaceutical Sealing Solutions

Specifications

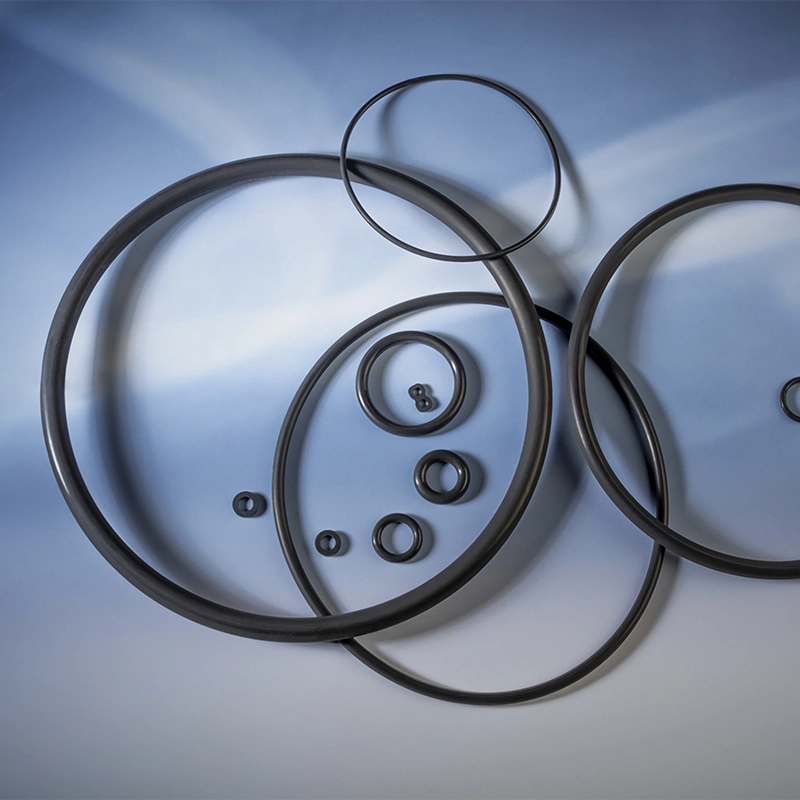

Chemraz® SD517 and Chemraz® SD625 are PTFE-like sealing materials built to handle the most challenging pharma manufacturing and processing conditions:

- Resistance to Q3C Class 3 solvents

- Minimal extractables in aqueous to nonpolar systems

- Cleanroom production and packaging (SD517 only)

- Very high thermal stability (up to 260°C)

- Long service lifetime compared to silicone, EPDM, or Viton™

- Long-term stability in common sterilization, pyrogen inactivation, and prion-destroying conditions (SD625 only)

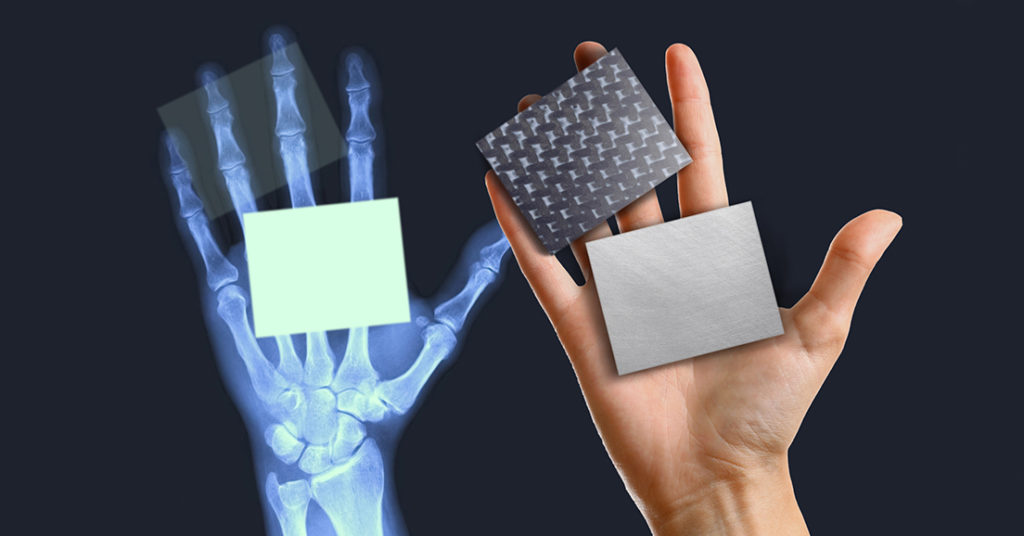

Carbon Fiber PEEK Performance

Specifications

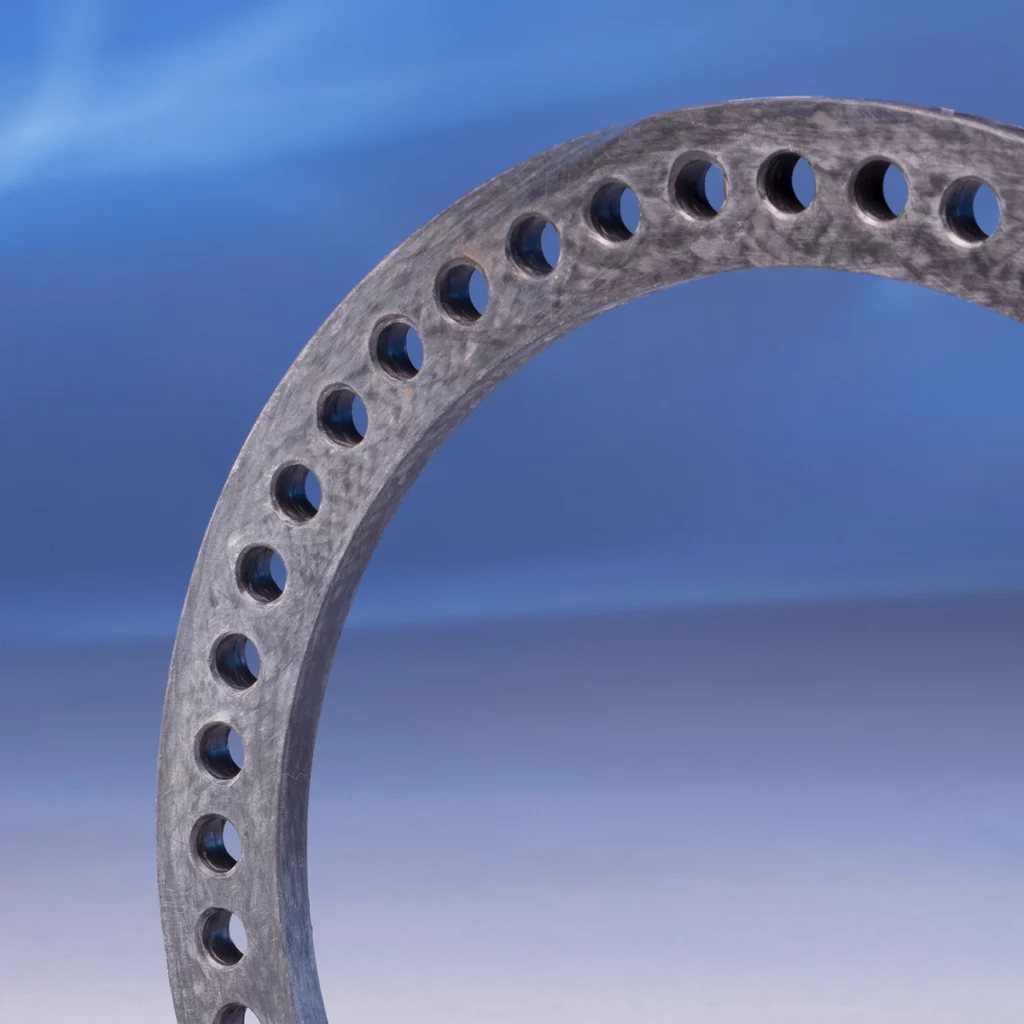

Our Orthtek® WF 50% carbon fiber PEEK composite outperforms metal and other plastics while reducing risk of strain, injury, and life-threatening errors:

- Lighter than metallic counterparts (1.54 g / cm3) for reduced strain and injury risk

- Radiolucent to improve x-ray clarity and limit patient exposure

- Comparable strength to metal

- Structural material for insertion jigs, fixator rings, and other external medical devices

- Available in small custom batches (10s of units) or larger mass quantities (100,000s of units)

Reliable Performance

Specifications

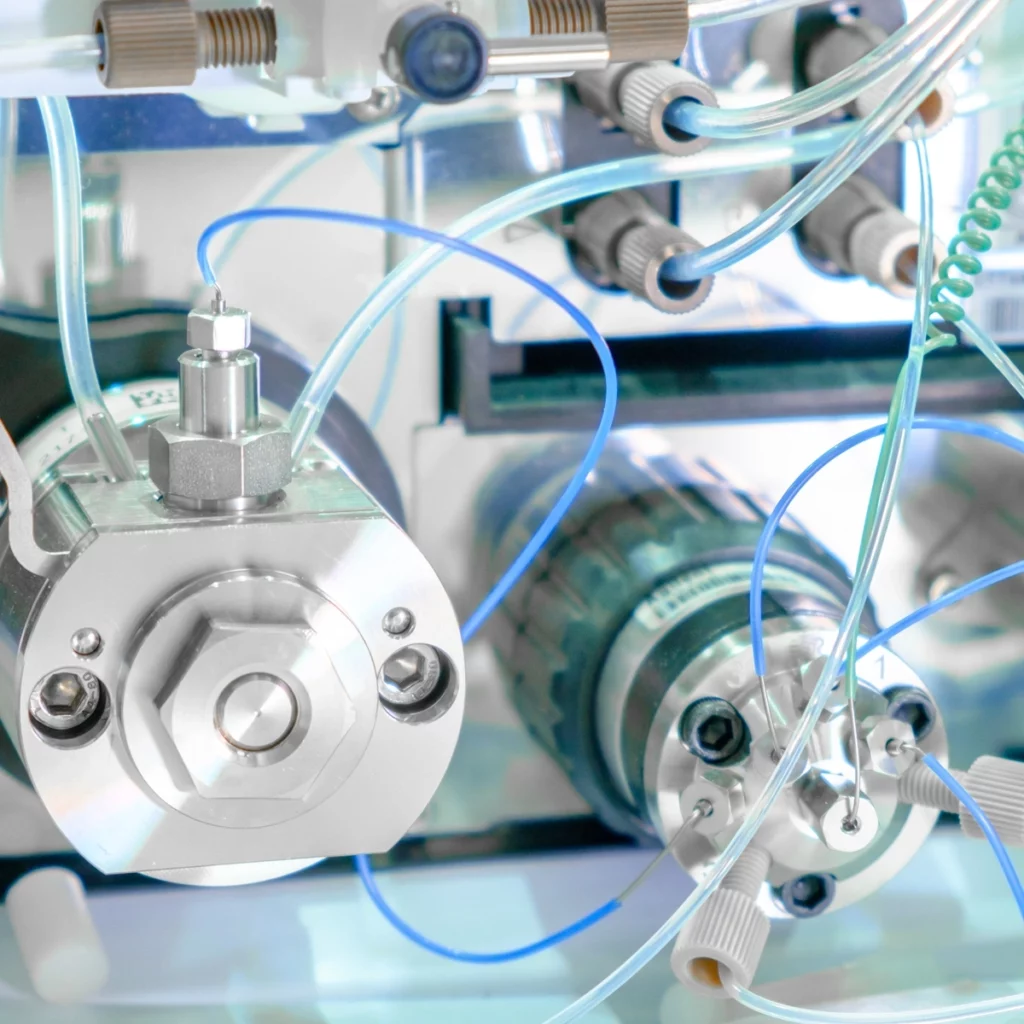

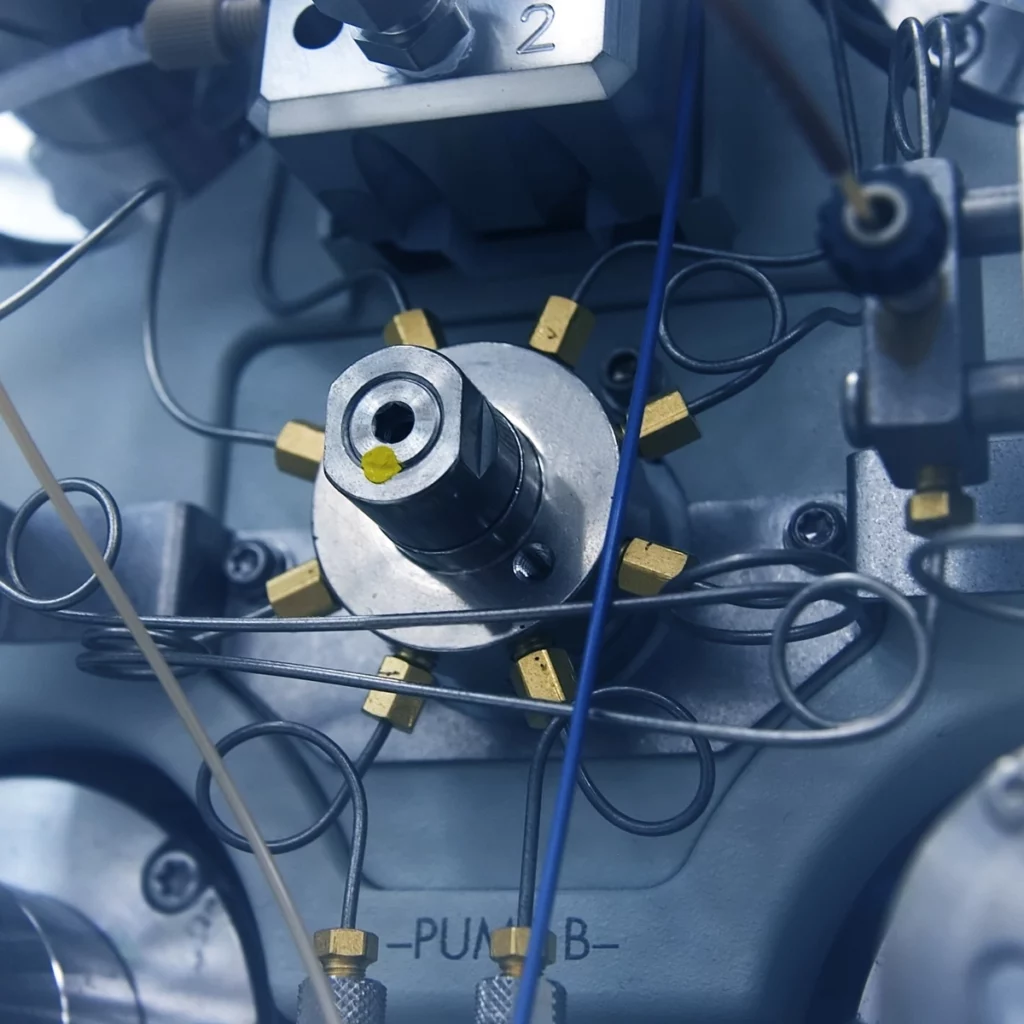

When it comes to HPLC and SEC instruments and in-process sensors, equipment failure is not an option.

Greene Tweed solutions are built to perform under extreme chemical, pressure, and temperature conditions, extending the lifecycle of your instruments and reducing costly downtime.

Boasting excellent compression rate and extrusion resistance, Chemraz® 605 is available in in standard parts, custom designs, or sheets.

FDA Certifications

Greene Tweed maintains the highest level of quality when it comes to our facilities, operations, and materials manufacturing.

Download relevant Life Sciences FDA certifications below:

Avalon® 87WS FDA Statement of Compliance

Avalon® 37 FDA Statement of Compliance

Avalon® 01 FDA Statement of Compliance

Avalon® 56 FDA Statement of Compliance

Arlon® 1000 FDA Statement of Compliance

Chemraz® SD517 FDA Statement of Compliance

Chemraz® SD585 FDA Statement of Compliance