At Greene Tweed, Innovation Begins with the Right Material

What is the key to Greene Tweed’s success in continually bringing innovative, groundbreaking solutions to the market? Selecting the right materials with a consistent approach is one of the most crucial steps.

Developing high-performance elastomeric and plastic components that outperform and outlast expectations in the world’s harshest industrial conditions is not easy. There are many factors to consider: extreme temperatures, pressures, and highly reactive chemicals in customers’ applications.

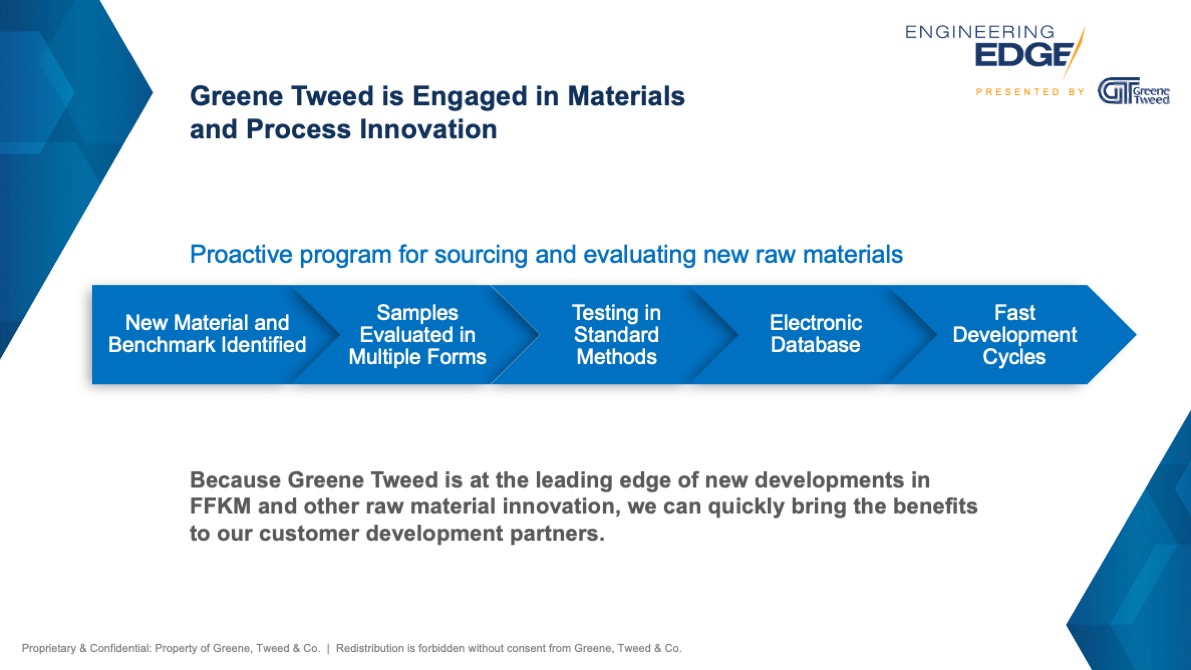

How does Greene Tweed approach material selection? We maintain a very proactive and systematic program for sourcing and evaluating raw materials in close collaboration with our strategic raw material suppliers. These collaborative relationships, along with our innovation programs, go a long way toward bringing high-performance solutions that meet the critical demands of the industries such as semiconductor, oil and gas, aerospace, industrial, life sciences, and chemical processing.

Evaluation Journey

Depending on the application, the process of unearthing new materials starts with close collaboration with supplier partners or an independent quest by Greene Tweed to scout for technologies across industries and research fields. These materials, whether polymers, curatives, fillers, or other additives, bring special functionality to our products. We always identify a benchmark to compare it against and that makes it easier to identify the potential advantages over the incumbent technology. Consider polymers as an example. A benchmark polymer is selected based on the similarity of polymer chemistry and architecture, cure system if required, and relevant known performance in an application.

Individual raw materials are often part of a compound where each component influences performance. This makes side-by-side comparisons of materials challenging, especially if there are synergistic effects with other components. Perfluoroelastomer (FFKM) polymers, for instance, are evaluated in multiple states. Initially, FFKM polymers are evaluated in an uncured state as received from the supplier, which provides insight into basic processability, operating temperature range, and cleanliness. Next, they are evaluated after incorporating the appropriate cure system, which provides a baseline performance of the crosslinked polymer without the influence of other fillers or additives.

The final assessment involves testing the polymer as a fully formulated model compound, typically chosen from a commercial product with known performance in application. This evaluation is most relevant for understanding the feasibility of quickly developing a new product with differentiated performance compared to the existing product portfolio.

Comprehensive Materials Database

One of the primary benefits of maintaining an ongoing material evaluation program is the resulting library or database of material properties. This database allows for the swift identification of candidate materials to meet the critical needs of a customer or industry.

The effectiveness of this database, however, hinges on standardized test methods and test conditions. To achieve this, Greene Tweed has defined test protocols that are based on either industry standards, such as ASTM, or internal standards that have been developed to align with typical application conditions. The generated data is then stored and maintained in an electronic database that enables easy searching, sorting, and utilization in machine learning or other predictive modeling programs.

The Bottom Line: The ultimate outcome of this material evaluation program is the ability to quickly bring solutions to our customer development partners. It’s the close collaboration with raw material suppliers, coupled with a well-maintained database of material properties, that allows for quick identification of raw materials to either bring benefits to strategic customer development programs or resolve supply disruptions if they occur. This strategic material initiative serves as the bedrock for Greene Tweed’s ability to engineer components that meet the critical demands of industries we serve.