Product Details

Increase Uptime and Processing Yields

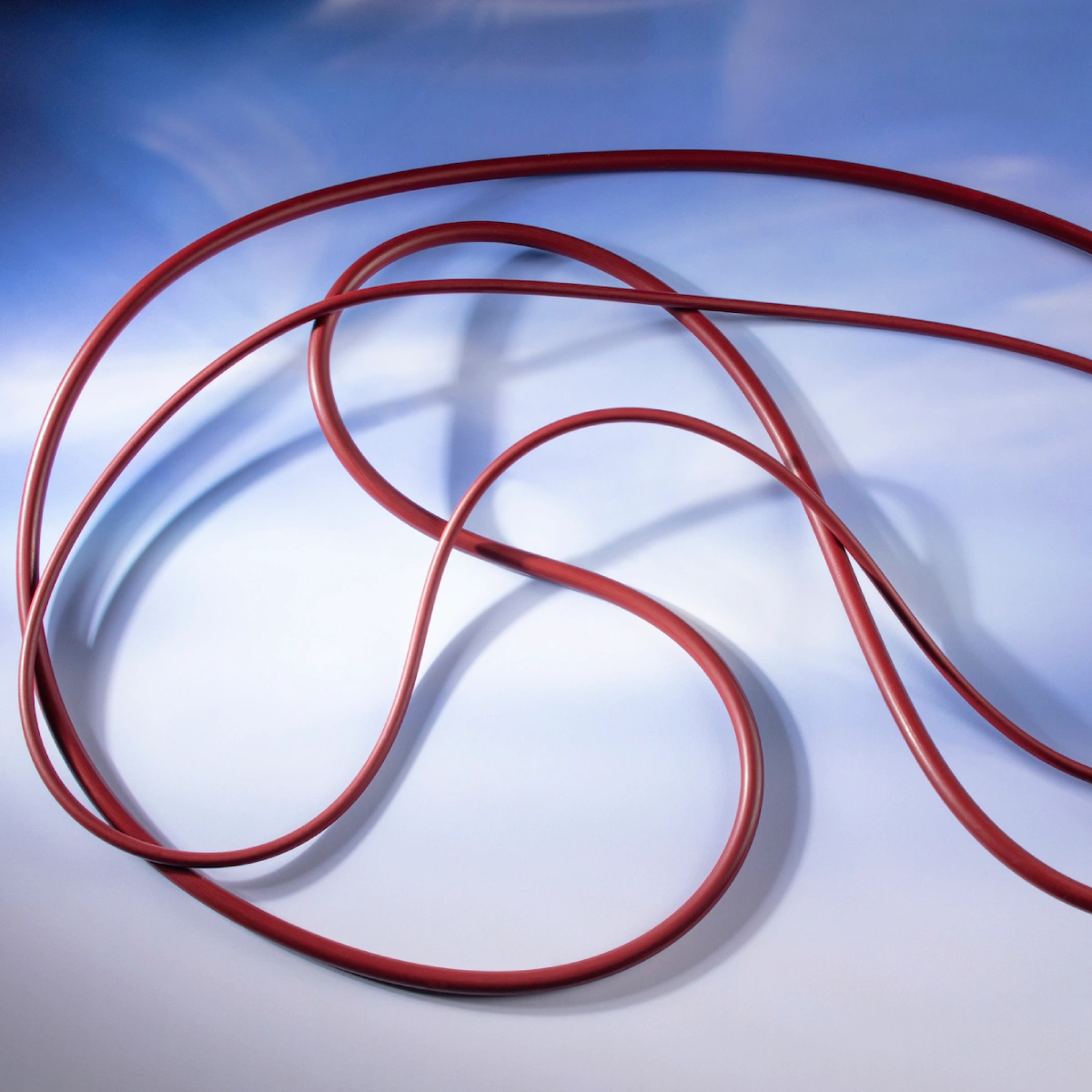

Do you need custom-engineered wafer processing seals that meet the demands of aggressive dry plasma systems? Chemraz® G57’s unique formulation provides improved plasma resistance and minimizes contamination, resulting in less downtime and higher wafer processing yields in both static and dynamic applications.

Chemraz® G57 is an FFKM compound with high temperature capability and excellent O2 plasma compatibility, boasting excellent chemical resistance and maximum temperature operation to 572°F (300°C).

Features and Benefits

- Excellent plasma resistance in a variety of aggressive chemical environments

- High service temperatures up to 572°F / 300°C

- Minimal particulation

- Lower hardness for easy installation

- Lower sticking properties for dynamic applications

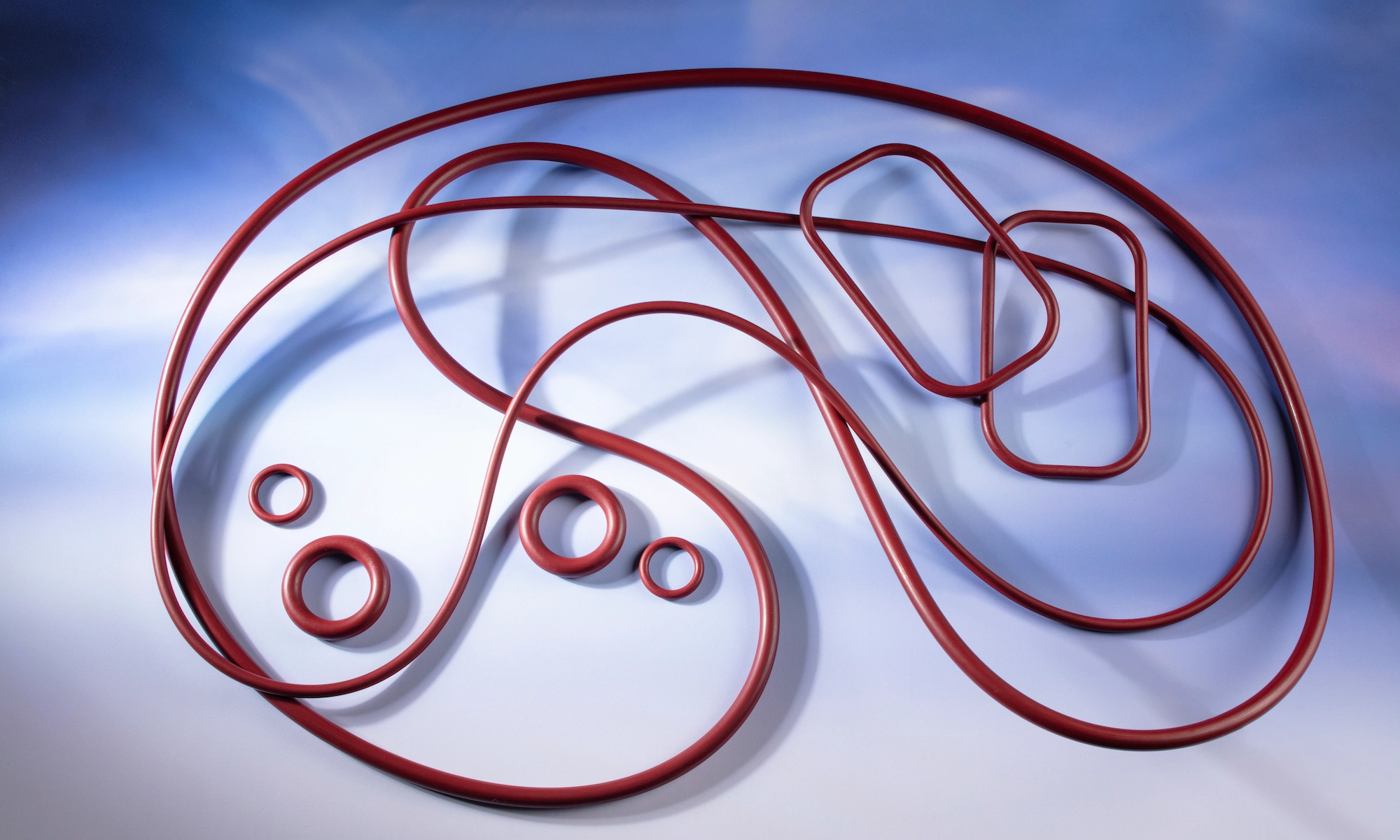

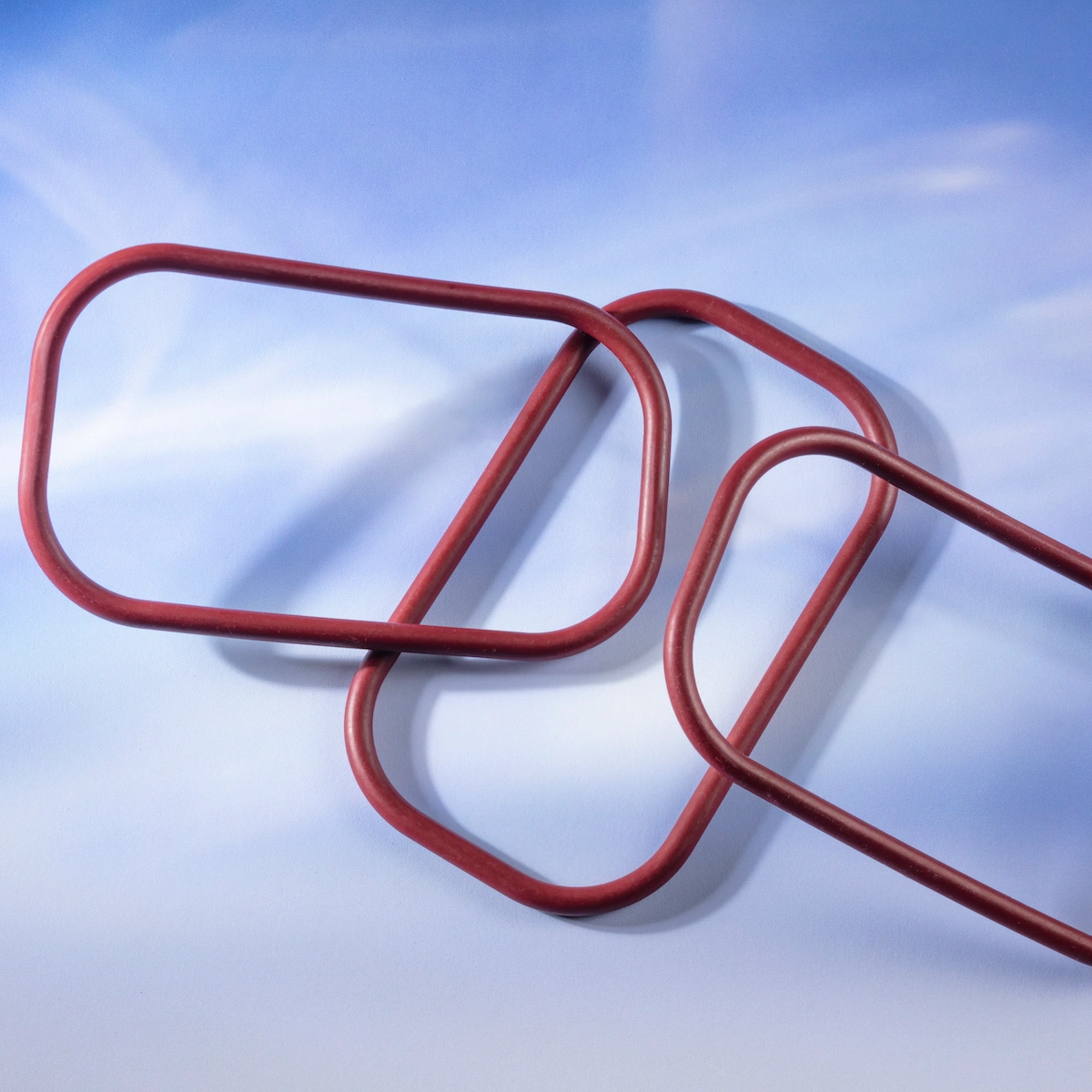

- Available as O-ring, custom CXs, and slabs – with no restrictions on availability

- Global manufacturing capabilities

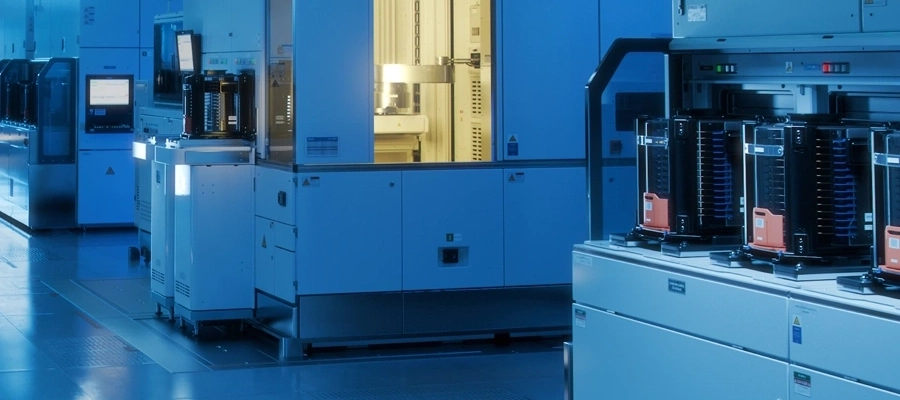

Industries & Applications

A high-performance elastomer designed for demanding applications

Chemraz® G57 products are designed for use across a wide range of applications. No matter how demanding the environment, our team works with you to determine the right solution for the job.

Applications include:

- Endpoint windows

- Seals

- Dy plasma etch

- Deposition

- Remote plasma cleans

- Dry ashing

- Oxidation

- Diffusion

- Metalization

Reliable Performance

Chemraz® G57 is a proven, reliable engineered component solution. It is available in the form of O-rings, custom CXs, and slabs.

Enhanced Plasma Resistance