All Your Semiconductor Sealing Questions, Answered

Do you need an elastomer o-ring or sealing solution built to withstand aggressive liquids, gases, and plasma at extreme temperatures found in the harshest semiconductor applications? Here are answers to the key sealing questions facing semiconductor manufacturers:

What kind of seals work best for semiconductor manufacturing processes?

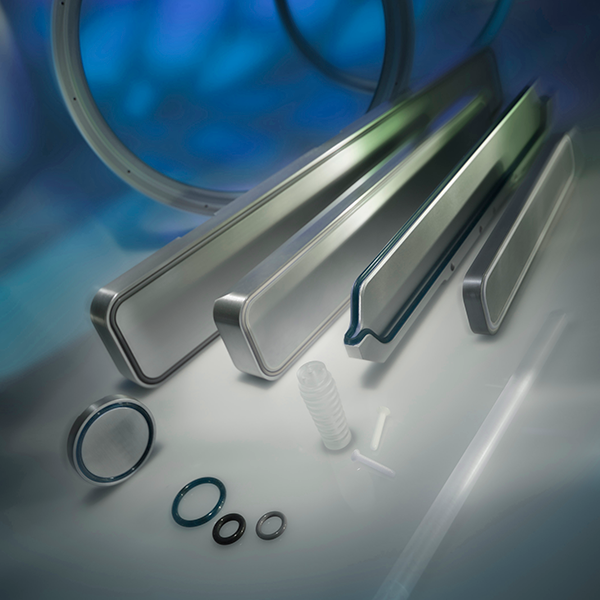

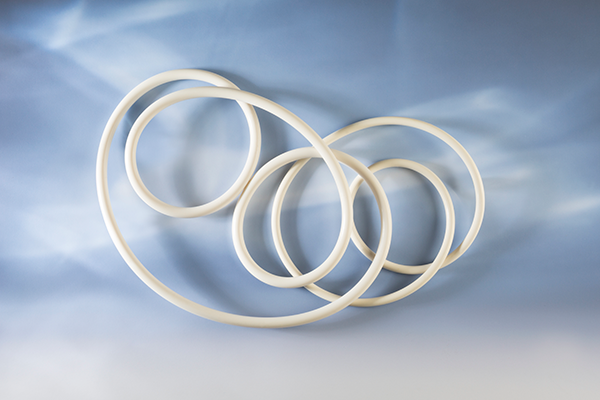

Perfluoroelastomer (or FFKM) sealing material, known for its exceptional resistance to aggressive chemicals, extreme temperatures, and plasma environments, is ideal for a manufacturing process as aggressive as semiconductor fabrication. Greene Tweed offers Chemraz® sealing solutions, known for their exceptional resistance to extreme temperatures, chemicals, and plasma environments.

What sets Greene Tweed’s Chemraz® sealing solutions apart?

At Greene Tweed, we take pride in our Chemraz® sealing solutions that are engineered to outperform and outlast in the world’s harshest environments. For 160 years, we’ve equipped critical sectors, including the semiconductor industry, with materials and engineered components that perform – no excuses, no exceptions.

With the broadest temperature range and unmatched chemical resistance among all elastomeric materials, Chemraz® is the prime choice for the most challenging semiconductor applications. Our superior quality, precision engineering, and customizability result in less downtime and higher wafer processing yields.

What kind of semiconductor manufacturing processes benefit from Greene Tweed’s Chemraz® sealing solutions?

Chemraz® FFKM sealing solutions are ideal for a wide range of semiconductor equipment such as:

- Conductor Etch

- Dielectric Etch

- PECVD

- ALD

- RTP

- Wet Cleans

- Chamber Seals

- Slit Valve and BSVs

- Pendulum and Gate Valves

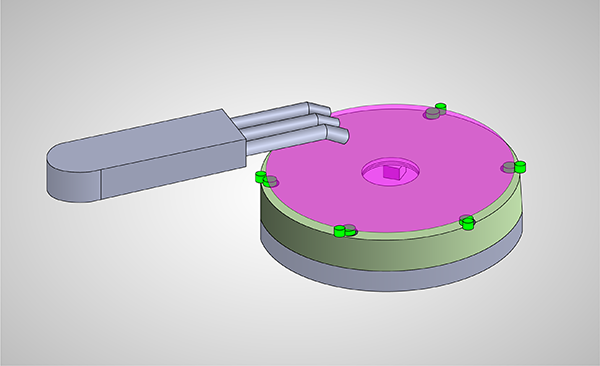

- Electrostatic Chuck and Pedestal Barrier Seals

- Chemical Delivery

Can Greene Tweed’s sealing solutions withstand aggressive cleaning and etching chemistries?

Absolutely! Chemraz® exhibits exceptional chemical resistance, making it highly compatible with aggressive cleaning and etching chemistries used in semiconductor fabrication. It remains stable even when exposed to harsh plasma environments and reactive chemicals, ensuring optimal performance and longevity.

Can Greene Tweed customize seals to suit specific semiconductor applications?

Yes, at Greene Tweed, we offer a range of sealing solutions that can be tailored to meet your specific requirements. Our engineering team works closely with semiconductor manufacturers to design custom seals that match equipment specifications and deliver optimized performance.

I want to implement Greene Tweed’s latest sealing solutions in my semiconductor application. How can I start the process?

To explore the benefits of FFKM sealing solutions tailored to your semiconductor equipment, reach out to our expert team at Greene Tweed. Our engineers are ready to talk about your specifications and provide technical guidance. We’ll keep working to iterate, improve, and deliver high-quality sealing solutions to elevate your semiconductor manufacturing process.