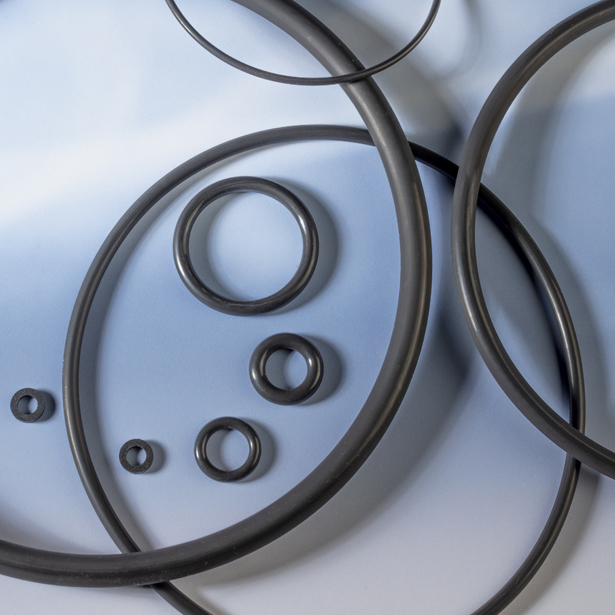

Choosing the Right O-Ring: What to Consider

Selecting the best O-ring for your application is a must to ensure operational efficiency and worker safety while minimizing the risk of equipment failure and costly downtime. There are several factors to consider when making your choice, depending on the industry, application, and environment in which the O-ring will be used. We take a closer look at each factor below.

Material

O-rings come in a variety of thermoplastic, elastomer, polyethylene, and other rubberized materials, each with its own unique properties, chemical compatibility, and resistance to extreme temperature and pressure. Before choosing a material, be sure to look at its properties sheet to ensure it is best suited for your application.

Hardness

Typically measured with a Shore A Durometer, the hardness (DH) of rubber materials is defined by its resistance to permanent indentation based on the amount of pressure they will be subjected to. A rating of 40 makes a softer O-ring that flows more easily into glands, bores, rods, and flanges, while harder materials with a rating around 80 provide greater resistance to extrusion.

PSI rating

The PSI rating of an O-ring measures how much pressure it can withstand without leaking. Sealing is the primary function of all O-rings; when deciding on shape and material, be sure the PSI rating meets or exceeds the pressure in the application.

Internal diameter and cross section

The internal diameter of an O-ring refers to the distance between its two widest points. Proper sizing is a must to ensure function and avoid leakage and costly equipment failure. The cross section of an O-ring refers to the thickness of the material used. While a larger cross section typically provides better leakage protection, the sizing must be appropriate to accommodate the parts and passages in which it is used.

Assembly

A proper assembly is necessary to avoid leakage and damage to the seal and other components. An O-ring can be cut, sheared, torn, twisted, and overstretched during installation, causing the seal to fail. To avoid O-ring failure, consider whether a lubricated or non-lubricated sealing solution is best – and be sure to slide the O-ring into place (don’t roll it) when installing.