Greene Tweed’s Fireproof Hydraulic Seal Solves Extreme Temperature Requirement Challenges in Aerospace Equipment

Devin Prate, Greene Tweed Technical Product Specialist for Sealing Solutions

With the onset of new aircraft programs over the past decade, the demand has increased for actuator designs that meet and exceed more rigorous performance standards while providing unprecedented safety and reliability.

Some of these requirements, such as the fire and flammability resistance defined in ISO 2685 and RTCA DO-160, go beyond the use of standard hydraulic seal designs. These high-temperature, challenging requirements significantly impact commercial aircraft engine safety, and often force the use of heavy, bulky, easily damaged and costly external fire shielding.

As a result, Greene Tweed developed the Fireproof Hydraulic Seal (FPH SealTM), which has been specifically engineered to meet this need and establish a shielding alternative.

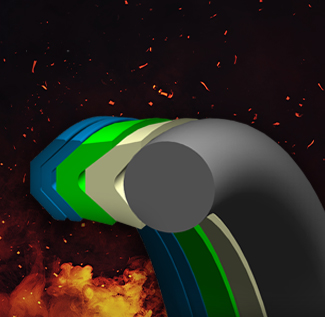

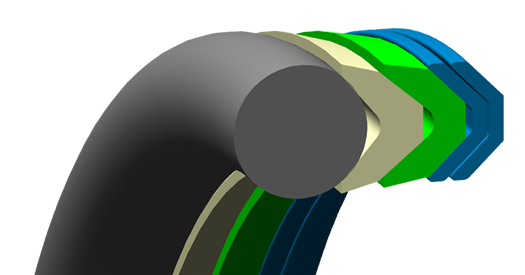

The FPH SealTM provides excellent high- and low-hydraulic pressure sealing in static fireproof-rated equipment by combining the tight leakage control benefits of an elastomeric o-ring with the high-temperature, high-strength capabilities of carefully engineered thermoplastic and metal support rings.

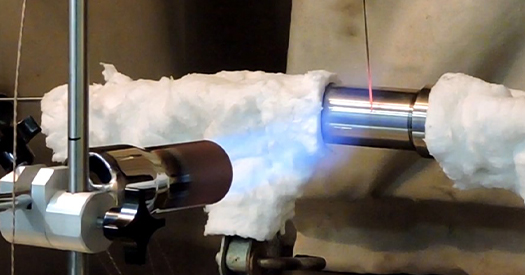

Validated through vigorous flame tests both in-house at Greene Tweed and at an outside laboratory, the FPH SealTM design resists pressurized fluid escape when a 2000°F (1093°C) kerosene-fueled flame is applied to the external surfaces of the actuator or test-unit housing for up to 15 minutes. Where standard o-rings and backup rings would significantly degrade and fail, the FPH SealTM undergoes a “controlled degradation” which allows it to survive the required duration.

The FPH SealTM is another example of Greene Tweed pushing the limits of seal technology. To learn more about Greene Tweed’s high-performance sealing solutions, click here.