How Semiconductor Fabricators are Working Through Global FFKM Shortages

The decade began with a semiconductor shortage that made the world acutely aware of how critical these tiny components are in many aspects of everyday life and for most sectors of the economy. Demand for semiconductors skyrocketed driven by a pandemic-led rise in remote work, distance learning, gaming, entertainment, internet shopping, data analytics, and soaring sales of vehicles, and will continue to grow, doubling the global chip market to over $1 trillion by 2030.

(Greene Tweed Elastomer Center of Excellence in Kulpsville, PA rapidly develops and tests new FFKM compounds to meet the demanding requirements of new semiconductor fabrication methods and to develop alternative materials to mitigate the current shortage of specific feedstock)

Keeping up with this demand, however, has been complicated by a different shortage — the limited availability of small but critical components required by the chip fabrication process: chip fabrication processes depend on the FFKM (perfluoroelastomer) O-rings, gaskets, and other seals that can stand up to the extremely high temperatures and aggressive chemicals while controlling particulate excursions that cause contamination.

Unsurprisingly, this has triggered an even higher demand for FFKM seals already popular in the semiconductor industry. While most manufacturers are expanding capacity as quickly as possible, demand continues to outpace supply – further increasing the need for FFKM materials and leading to shortages. The current global shortage of FFKM is caused by limitations in the supply of raw materials occurring at the same time as the acceleration in demand for FFKM products.

Rapid Development of New Product to Mitigate the FFKM Shortage

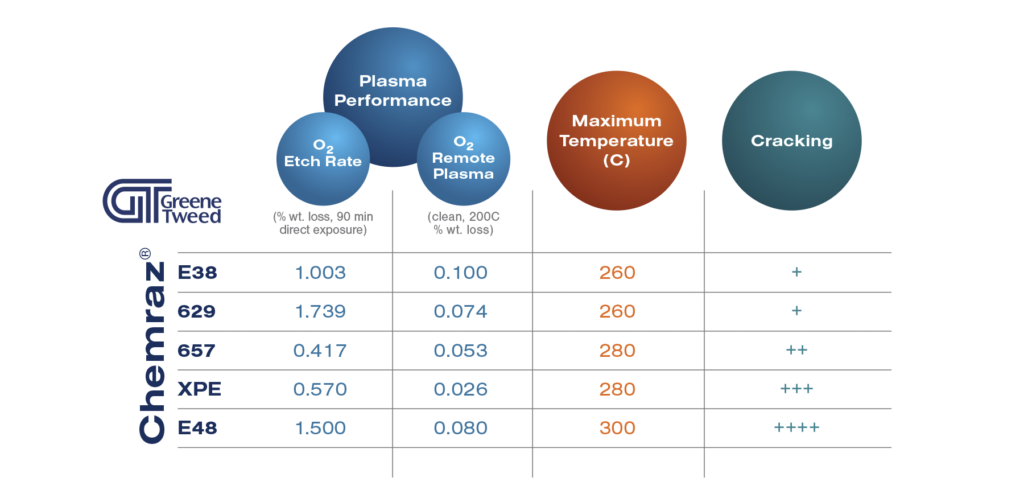

The Elastomer Center of Excellence located at the Greene Tweed Advanced Technology Group Headquarters in Kulpsville, PA, has prioritized its work to focus almost exclusively on developing substitutes for supply constrained Chemraz products that our semiconductor customers have identified as most critical to their operations.

These new formulations are subjected to rigorous testing to ensure that they meet the extreme thermal and chemical resistance requirements of demanding semiconductor fabrication applications without causing harmful particulation.

The first replacements to be released will be materials equivalent to Chemraz 657 and Chemraz E38, for dry plasma and O2 plasma etching processes requiring minimal contamination. These new product offerings will be available for testing on a limited basis in late 2022 and generally available in mid-2023.

To learn more about how we are mitigating the FFKM shortage, read the article originally published in Silicon Semiconductor and Power Electronics World