Do You Know the Right Surface Finish for Your Seal’s Mating Hardware?

Imagine a sealing system on your equipment just failed prematurely or isn’t functioning properly. You might immediately want to check if the seal is defective or if the seal material could not withstand your application’s temperature or pressure requirements. Or wonder if it was the right size or verify the squeeze level.

But what about the mating hardware? Well, some aspects of the hardware design could make or break a seal’s ability to function properly and could impact the dynamic lifetime of a sealing element. Surface finish – the roughness of the two hardware faces compressing the seal – of the mating hardware is one such factor that should be considered during design, as the ideal surface finish will determine sealing performance and can maximize the life of the sealing element.

Surface finish requirements depend on whether the seal is elastomeric, thermoplastic, or another material. The overall malleability of elastomers allows for greater variation conformity in the surface finish, while more rigid thermoplastics are less conforming but can sometimes require less lubrication due to their tribological properties. That’s why the surface finish recommendations for a thermoplastic seal are generally for a finer finish than an elastomeric seal would require.

Additionally, surface finish requirements are different for applications that seal liquids from applications that seal gases or vacuum. For gas sealing or sealing against a vacuum, a finer surface finish is recommended as the structure and size of most gasses allow them to pass through smaller gaps than a liquid would be able to move through.

In a dynamic application, hardware surface finish will also directly affect the lifetime of a seal. A variation in the hardware surface is needed to trap process media or lubricating fluid at the surface to reduce friction. However, if the surface is too rough, the sealing element will be abraded by moving against the hardware. Finding the correct balance to both provide lubrication and maximize seal lifetime is critically important.

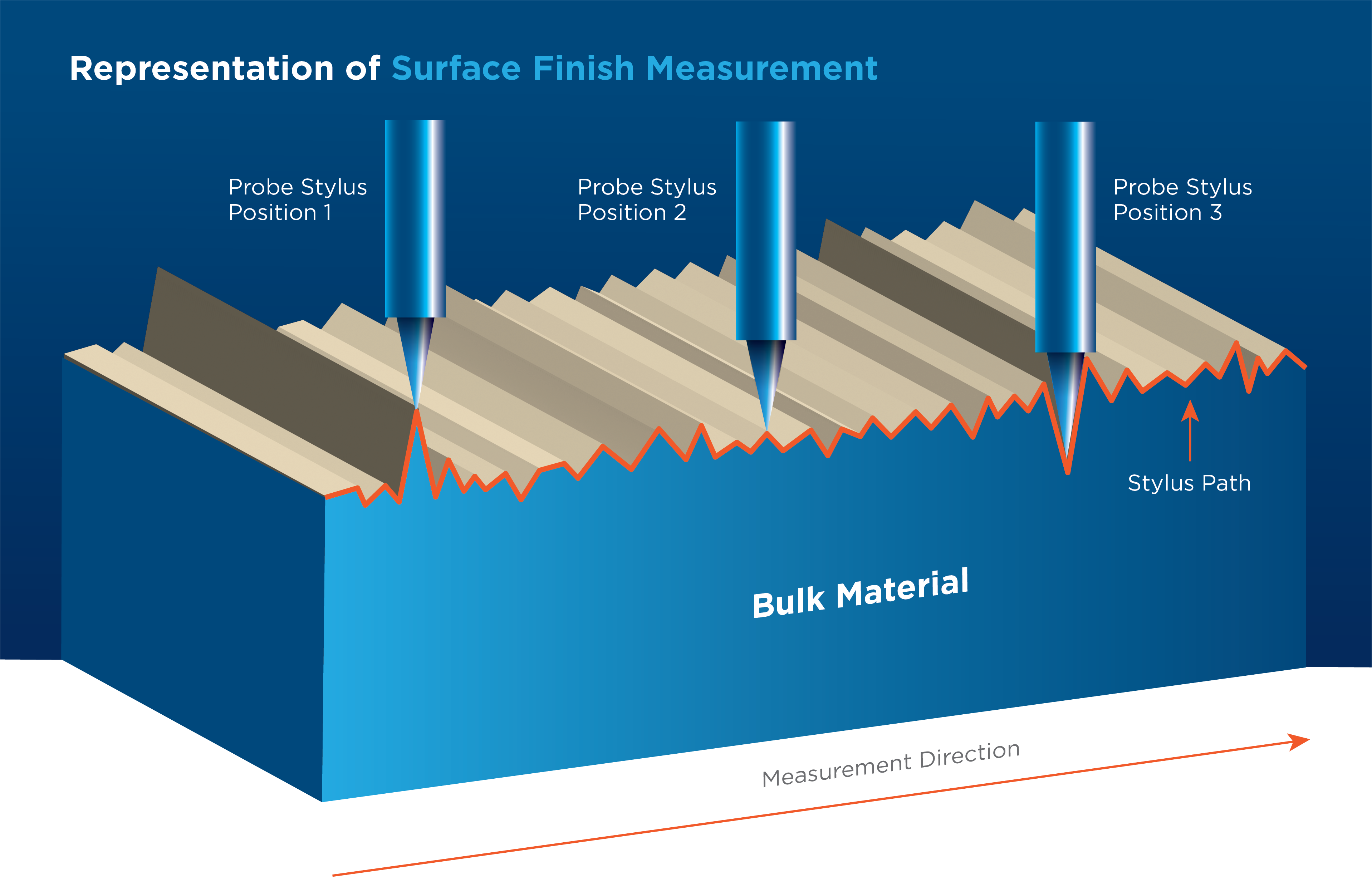

Below is a depiction of the localized variations in surface height and roughness that shows how surface finish measurements are made in a general sense. It is easy to imagine that if there were too many of the peaks like the one towards the left of the diagram, seal materials would be abraded or worn away by dynamic contact, not to mention having trouble conforming to all the variability in localized surface height. Also, the valley towards the right of the image demonstrates how a pocket is formed, which could allow trapping of the process media or lubricant for decreasing the friction through continuous dynamic cycles.

Choosing the right surface finish for the hardware components in your application can be complex. In general, we recommend 8 to 12 microinches Ra (Average Roughness) for dynamic seals, and 16 to 32 microinches Ra for static seals. Greene Tweed’s experienced engineers can help you by accessing your application parameters to guide you to the right surface finish.