Greene Tweed In Silicon Semiconductor

Silicon Semiconductor featured Greene Tweed executives in an exclusive video interview that delved into the intricacies of the supply chain resilience strategy, designed to face potential disruptions and the cyclical nature of the semiconductor business. Nick McNeal, Director of Semiconductor Strategy, and Thyag Sadasiwan, General Manager of Chemraz® Business Unit, detail how they are diversifying, launching new products, and expanding manufacturing footprint to ensure a steady supply of sealing solutions and engineered components that outperform and outlast in the world’s harshest plasma and aggressive chemicals used in semiconductor wafer fabrication process. Explore the expertise, innovation, and commitment that define Greene Tweed’s vision in the transcript of the wide-ranging discussion with Silicon Semiconductor editor Philip Alsop:

Philip Alsop (Silicon Semiconductor):

Can you provide us with an overview of the company's products, bearing in mind the nature of today's discussion, particularly how they play within the semiconductor industry, that'd be good to understand.

Thyag Sadasiwan (Greene Tweed):

That'd be great. Let me just start by introducing myself very quickly, and then in Greene Tweed. So, my name is Thyag Sadasiwan and I manage the Chemraz® Business Unit at Greene Tweed. My background involves several industries ranging from transportation to energy, aerospace, and semiconductors. Let me talk a little bit about Greene Tweed. Greene Tweed designs and manufactures components, materials and solutions that perform in the harshest environments. We also engineer for conditions where equipment failure is not an option.

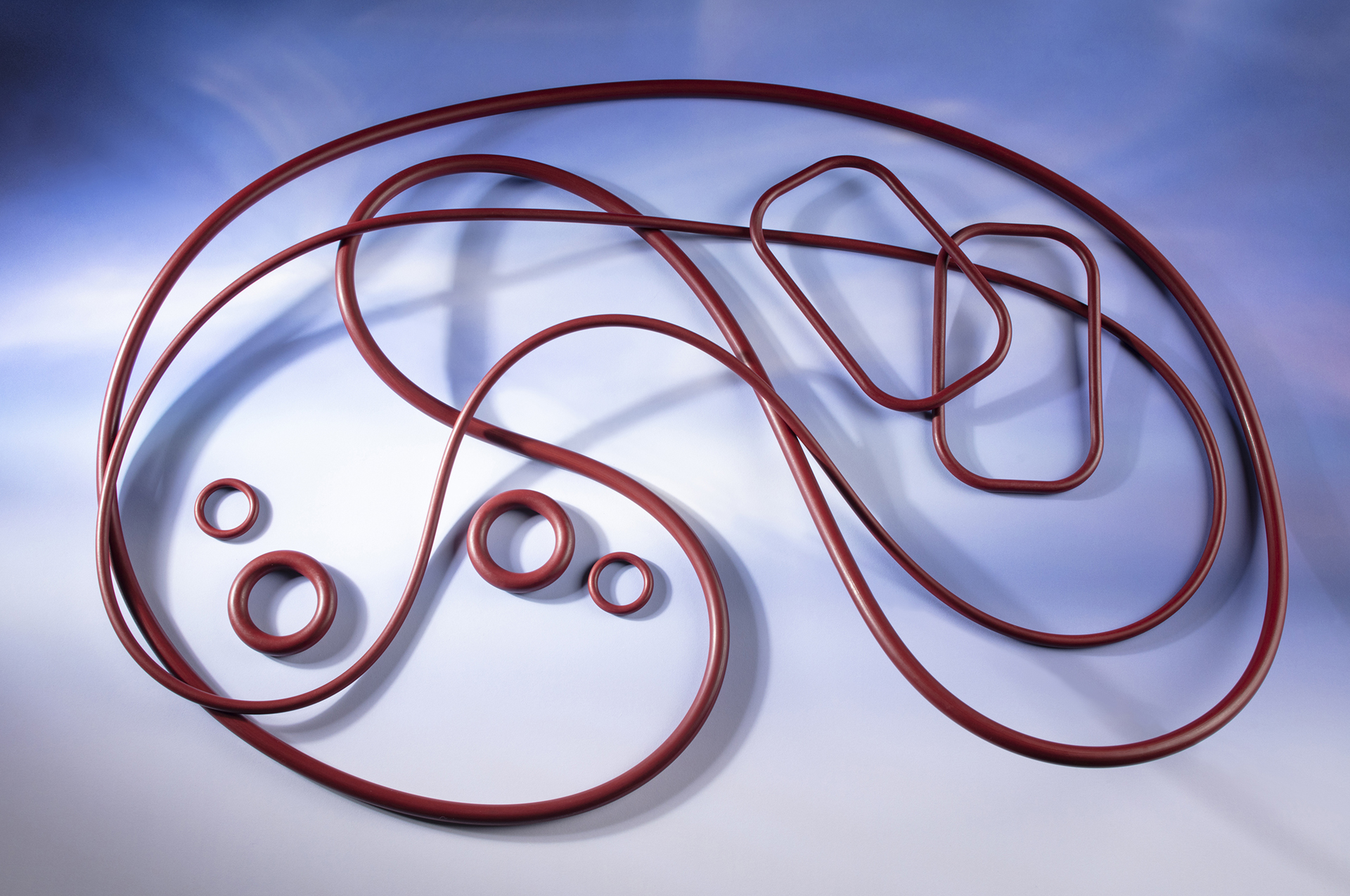

Our products are made for extremely high temperatures, pressures, chemical corrosion, mechanical wear. In some of our business units, like our sealing solutions business unit, we supply products for subfabs and other areas of semiconductor manufacturing. In our engineered components business, we design and manufacture products such as Onyx® and Arlon® for wafer handling. And then specifically in our Chemraz® business unit, we design and manufacture high-end sealing solutions, many of them with very complex geometries and advanced materials to meet our customers’ requirements.

Nick McNeal (Greene Tweed):

Yeah, so thanks for that Thyag. So, I'll do a brief introduction really quick here too. My name is Nick McNeal. I'm the director of the semiconductor industry strategy globally here at Greene Tweed and so what's specific to the semiconductor industry, what Thyag mentioned is really what allows Greene Tweed to be in the business of providing world-class solutions using our full suite of materials and seal designs.

So, we've got teams of industry experts really in all facets of our business, from engineering, to account management, to manufacturing who all look at and understand the challenges in the market and what's on the horizon, and then design for those demands. And so that could be in the form of a standard O-ring, something everyone's pretty familiar with, or something as complex as a custom-bonded slip valve door, or even a full-on turnkey tool component that improves some facet of performance or reliability within the process. And so, these solutions can exist really anywhere within the industry, and that's where we invest.

Philip Alsop (Silicon Semiconductor):

Okay. And it would be good to understand, following on from that, what it is that makes your sealing solutions ideal for, obviously, there's some harsh plasmas, the aggressive chemicals that are used in the wafer fabrication processes. So, what is it that makes the Greene Tweed products particularly suitable for those harsh environments?

Thyag Sadasiwan (Greene Tweed):

Yeah, it's a great question, Philip, thanks for asking. Greene Tweed, as you know, has been poaching the boundaries of material science for over 150 years. Semiconductor manufacturers are constantly innovating, so we know that. We are looking to fit more and more complex devices on smaller footprints. When I say smaller footprints, we are talking about sub-seven nanometers. For perspective, what that means, a nanometer is a billionth of a meter. It's about a hundred thousand times smaller than the width of a human hair. And to shrink it below that, it's going to, chips are going to go 3D. So, you're not only going to be able to stack it in 2D, but you’re also going to go three-dimensional, like 3D9 is one of them. And to do so, manufacturers use these extremely advanced techniques in their clean rooms. We have to manufacture in turn our products that we supply to them with many of those same specifications in our factories.

We have to ensure that our seals don't have material loss. They don't contaminate the semiconductor wafer manufacturing processes and are subject to extremely high temperatures and harsh chemistries. And these chemistries are used in processes like etching, in semiconductor manufacturing. These seals cannot also shrink or undergo any kind of mechanical distortion when they're subject to extreme stresses. Since the specific power and thermal profiles of some of the semiconductor manufacturers is an intellectual property, they consider it their intellectual property. We have to design our products to operate over a wide range of temperatures, pressures and flows, which significantly increases the complexity for suppliers such as us.

So, our design engineers work closely with equipment manufacturers and their end users to create solutions that are more resilient, more efficient, and sustainable. We also secured the most advanced polymers from leading FFKM suppliers. Last but not least, we work closely with our suppliers on experimental samples, and we provide feedback during their development cycles. So, we are still looking back into the supply chain and making sure we're taking steps in the supply chain to bring the next-generation products to our customers. And we have a large, experienced team that combines several decades of application experience with very advanced material chemistry to create products and solutions for wafer fabrication as well as advanced packaging.

Nick McNeal (Greene Tweed):

Yeah, so I just want to drill down on something that Thyag mentioned there, and that's the relationships that we have with leading-edge raw material developers within the value chain. And so, when we engage in development programs with our customers, it actually instills a pretty significant level of confidence that we truly have access and know how to provide proper solutions using the proper technologies available in the market. And this ensures that their existing and next generation product requirements can be met. So, it also empowers our customers to actually provide us with feedback pretty early on, I think, in the development process. And this fosters this really advanced form of collaboration that enables our teams to iterate on both the material science side as well as the manufacturing side. And that helps us get to those meaningful results for the task and goals at hand.

Philip Alsop (Silicon Semiconductor):

Okay. And to that point, I believe you've fairly recently launched two sealing products, so it'd be good to understand a little bit about the, I guess, the key features and most importantly for the users, the benefits that those features will give them.

Nick McNeal (Greene Tweed):

Yeah, sure, sure, that's right. We have recently launched two new products. I'm glad news travels fast. The genesis of these products was truly spawned out of some of the chaos that existed in the last 18 to 24 months within the raw materials space. So, we've seen all kinds of disruptions, force majeures, political unrest, I mean, which candidly speaking, this created a ton of chaos within the floor polymer space specifically. And so, we kind of thought, what better way to prepare for the future than by learning from that past? And so, two of our most popular FFKM materials are known throughout the industry are Chemraz® E38 normally used for edge processes, and then Chemraz® 513, which is normally used for deposition processes.

So as a part of, again, leveraging our relationships up the value chain, our teams of chemists have formulated what we like to call our supply resiliency portfolio. Now, the first two materials that we've launched within this category of materials are G38 and G13, kind of intended to be kind of twin materials to the ones that are known so well within the market. So not only do these materials provide a level of supply redundancy for our customers, but they also provide a broader value proposition for some of those customers with longer preventative maintenance cycles. Thyag, I don't know if you want to add to that.

Thyag Sadasiwan (Greene Tweed):

Yeah, it's really well put, Nick. So G38, as Nick mentioned, is focused on edge processes where the seals are subject to oxygen, plasma, and long-term thermal sustainability and thermal stability. G13 on the other side is used for deposition, which is the other side of the plasma processes, specifically for plasma-enhanced chemical vapor deposition and plasma-enhanced atomic layer deposition. So that's where these products excel. And as Nick mentioned, we have products that have been stable for a very long time, but because the environment is changing, we have to make sure that business stability is assured for our customers. The key here is to really understand that the base FFKM polymers are not interchangeable across application needs. So, if you lose materials in high-temperature space, you cannot just replace them or substitute them with materials in low-temperature space. At Greene Tweed, we have unique insights into some of these applications. Our products perform as well as the design. In addition to some standard products, we have some very unique application-specific solutions that our customers need and have come to expect from us.

Philip Alsop (Silicon Semiconductor):

Okay. And Nick, you alluded, I think at the start of your answer there, around the supply chain and some of the challenges that have been experienced. I mean the industry's, I guess, cyclical by nature. Clearly, some things arrived that no one was planning like the pandemic or the various conflict areas, but the semiconductor manufacturers are obviously concerned about supply chain disruption. And I'm just interested as to what Greene Tweed is doing, if you like, at the present time to help ensure uninterrupted supplies for those people, but also longer term in terms of your supply resiliency strategy, anything you can share on that as well?

Nick McNeal (Greene Tweed):

Yeah, yeah, Philip, that's a great question because look, the semiconductor industry is known for both its cyclicality and its seasonality. And so, as a leading market solutions provider, we have to be prepared for that and be able to build a portfolio and a business model that's prepared to support both the ups and the downs. So, like I mentioned a moment ago, there were significant disruptions primarily caused by upstream from us that just happened when demand was peaking. And so today, in the wake of that, we've actually seen a glut of excess inventory at a lot of our customers that have been created by some fearful buying patterns in order to secure supply. And then you combine that with one of the larger downturns in recent memory, it's caused a little bit of a pent-up situation. And so, while it might seem like the supply chain issues have kind of been overcome, the underlying constraints that existed 18 or 24 months ago, they could rear their head again at any moment.

And so, we want to make sure that we're prepared for that. And so, in order to do that or any other supply hiccup, that's going to go back to one, the intimacy that we have and that we maintain both up and down the value chain so that we can anticipate those challenges, but also preparing for those redundancies like G38 and G13 that we were talking about. And to be clear, I want to be very clear about this actually, we don't anticipate or see any significant supply disruptions currently or within the near future that would impact any of our tried-and-true materials like E38 or 513. But developing and investing ahead of that curve is what allows Greene Tweed's Chemraz® customers to evaluate these new offerings and kind of give themselves the option for an enhanced business continuity plan as we enter what's looking like a new cycle of renewed demand.

Thyag Sadasiwan (Greene Tweed):

Yeah, thanks Nick. Philip, you touched upon the potential supply chain disruptions at the heart of some of this. In the very recent past, a lot of our customers remember we all heard 3M's public announcement of their exit from FFKM manufacturing by 2025. We've had to focus a lot on the mitigating impact with some of our customers. Now that those solutions are in place, we are proactively working with other suppliers to understand what risks exist in their supply chain. We always looked at our manufacturing, our factories, maybe at step one of our supply bases. Now we are going two steps backward. We've got plans in place for our own manufacturing as well as our suppliers now. This is a continuous process. Nobody can get ahead of it. So, we stay on top of these as much as we can, so our customers can rely on us for their business continuity.

We plan for things like geopolitical instabilities, environmental issues, climate issues, and other disruptions. Greene Tweed, as you know, is one of the largest buyers of FFKM polymers in open space.

We have several suppliers globally and we manufacture products in the US and in Asia. Earlier this year, we just announced plans and broke ground for a new factory in Korea as well. As leaders in this high-performing sealing space, we work both with our customers as well as our suppliers on inventory strategies to ensure end-to-end supply resiliency. In the semiconductor industry, we believe the sealing market will experience supply constraints between now and 2027 because there's not enough polymer to take care of the existing and new demand that's going to peak. Now whether it's driven by a demand surge or whether it's driven by some specific technological advancements like AI and variable devices or just additional disruptions in the supply chain, we are prepared for all of that. Our investments are focused on ensuring our strategic customers and partners that want to collaborate with us are shielded from all these constraints.

Philip Alsop (Silicon Semiconductor):

Okay. And I'm wondering, as part of the resiliency strategy, have you developed or are you in the process of developing any complimentary products that will help address some of the challenges? And also, in what ways do they enhance your existing portfolio for the semiconductor manufacturers?

Thyag Sadasiwan (Greene Tweed):

Yeah, I'll touch briefly on this. In fact, our entire portfolio has been revamped. We have all the existing products in our portfolio that customers rely on today for the next generation, as well as to ensure supply chain resiliency. We've got a whole set of new products called the G Series, and the G series of Chemraz® sealing products are part of that resiliency strategy. For the semiconductor industry specifically, we have G57, G38, and G13, just to name some of them that we just talked about recently.

These products, it's really important to understand they will coexist with our existing products because the industry has copy exact standards, so they don't want to shift when they don't have to. Applications where these products, the differentiation in these products provides meaningful value, differentiation, and value proposition to our customers. That's where we expect our customers to switch and continue onto new applications. Do you want to add something to that, Nick?

Nick McNeal (Greene Tweed):

Yeah, yeah, yeah, yeah. Thanks Thyag and I'm glad you touched on copy exact because look, that continues to be kind of the golden rule of the semiconductor industry. I think pretty much anybody listening to this broadcast will appreciate that. However, we have heard and seen some of the largest, most influential folks within the industry also mention the term copy closely. Look, frankly speaking, this is a direct recognition that those supply disruptions that we mentioned earlier absolutely had an impact on the industry as a whole. They were looking for other avenues to potentially keep their lines up and running when some of these disruptions were happening. And so that's not to say that a copy closely solution could be dropped right in with no evaluation or testing, and that's not what we're suggesting with our growing suite of G series complimentary products. Our goal was to develop something that was close enough to the original that customers could actually be confident in building their supply resiliency strategies and then potentially offer a shorter qualification program due to the performance characteristics and benchmark data that we've been able to create as we've launched these products.

And then obviously also potentially offer a refreshed value proposition. Now, as we continue to invest in our resiliency strategy, we don't necessarily, we're not pushing our customers to go out there and switch existing applications to newer products unless they see tangible benefit that are going to outweigh the cost of switching and testing all the things that we know the semiconductor industry does. But at the same time, a lot of our customers are recognizing that we're doing this, and that supply resiliency is more than just about having multiple suppliers. It's about ensuring that your existing suppliers have built-in supply resiliency, and so you're no longer under the illusion of this robust supply chain by simply dual sourcing. And so, to that effect, our customers are starting to test the new products that we're offering and have shared their product roadmaps with us so that we can kind of intersect at the key inflection points that have been happening and the ones that are coming down the road. So, it's been a pretty good revelation for us and, as Thyag said, at refreshing of our portfolio.

Philip Alsop (Silicon Semiconductor):

And I think in one of you, in the answer there, referenced Korea, and I think you have expansion plans there so it'd be good to understand a little bit about what those are, and again, clearly what relevance they have or what benefits that your customers will see as and when those plans come to fruition.

Nick McNeal (Greene Tweed):

Yeah, thanks for picking up on that, Phil. It's exciting to talk about, right? Because it was an exhaustive search. Ultimately, we landed in Korea as our new factory location, I believe that was announced really this past summer. Kind of had a lot of discussions around SEMICON West timeframe on when we were announcing that. And we're all really excited about it here. Look, our Korean facility is going to have the same world-class standards.

We're going to hold it to the same world-class standards that we do for all of our other production facilities, but we're really going to raise the bar for seal manufacturing because we've got some planned automation and just some new unique things that we can do with this new facility that we're, well, we can just see on the horizon that's really going to, we feel like revolutionize the way that we can supply the market as well as the way that we manufacture some of these custom solutions that we're talking about. So, we expect the factory to be up and running and really ship products, supporting our customers by probably this time next year, like fall of 2024. Thyag, this is kind of more your lane. I'll let you add anything.

Thyag Sadasiwan (Greene Tweed):

Yeah, from an operations standpoint and getting the factory up and running, a lot of credit here, the initiation of this factory, the idea, the concept goes to Nick. He really led the way for our semiconductor strategy and in spite of semiconductor demand being down right now, Nick was very firm in terms of where we have to expand and how we grow. So again, I give a lot of credit to Nick for doing that. We continue to track to our program-

Nick McNeal (Greene Tweed):

Team effort.

Thyag Sadasiwan (Greene Tweed):

... there you go. We continue to track our program plan for the new factory. We'll engage in customer qualifications by early summer to head the dates that Nick set out. Initially, we'll meet all the needs of our direct and indirect customers in Korea from the factory. Then phase two will have plans to expand beyond that and service most of Asia. And beyond that, we plan to track shipments worldwide by 2026. We expect to essentially double our overall capacity of Chemraz® in the next five to seven years to meet the growing demand for semiconductor space.

Along with automation as well as a new factory playing a key role in that vision. Our factory will support other businesses within Greene Tweed, which is a really important point, and we are excited about having this opportunity to collaborate with our customers and provide them with the very best. Now, Philip, I can't wait to be talking to you again in the next year. We have a lot more interesting innovations coming out of the factory that we are working on today. So, we'll keep you posted.

Watch the video here.

Bios

Nick McNeal, Director, Semiconductor Strategy As Director of Semiconductor Strategy, Nick McNeal leads Greene Tweed’s customer relationships and market expansion in the semiconductor business. His strategic vision and proven track record in orchestrating successful business initiatives have played a key role in expanding the company’s operations and generating sustainable growth. Nick has over 18 years of experience ranging from engineering to product management to managing customers in global business segments and implementing value-added solutions that drive profitable growth.

Thyag Sadasiwan, General Manager, Chemraz Business Unit, Greene Tweed Consistently viewed as a high-energy and results focused business executive, Thyag Sadasiwan leads Greene Tweed’s Chemraz® business unit. With a background in commercial and operational leadership, his career expanded over several industries including transportation, energy, industrial, aerospace and semiconductor. Thyag worked his way up from an entry-level engineering position to serving small and large organizations as a senior leader. He is passionate about helping customers and industry stakeholders learn about leading technologies and supply chain solutions they need to succeed no matter what this marketplace does.