How Greene Tweed Can Help You Unlock Hydrogen’s Power

This is the second article in a series on Hydrogen and its Challenges. Read Part 1

It is hardly surprising that hydrogen is catching everyone’s attention, from environmentalists and governments to boardrooms across the world. It is a very important piece of the Net Zero puzzle and investments in hydrogen production are set to exceed billions of dollars.1

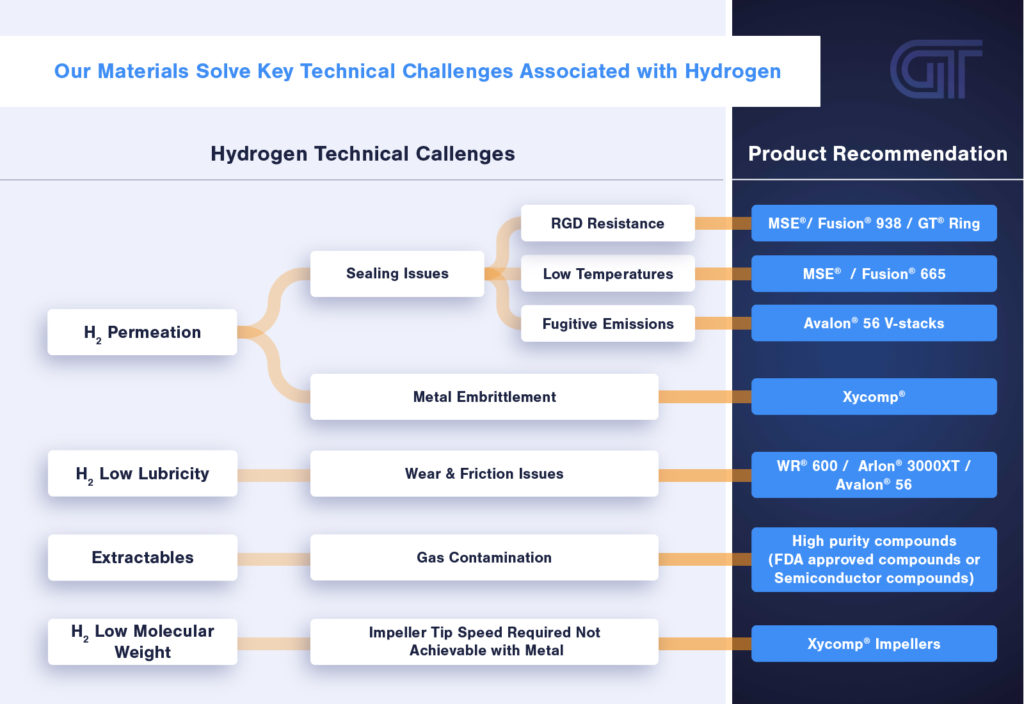

Yet, the majority of the equipment and processes needed to produce, store, and transport hydrogen are not ready to start working with it. Some of the biggest challenges presented by the tiniest, lightest molecule known to man include:

- High permeability of hydrogen can cause sealing issues and metal embrittlement.

- Hydrogen’s low lubricity can lead to wear and friction issues.

- Impurities in hydrogen can cause contamination of fuel cells.

- High impeller tip speed required to compress hydrogen with centrifugal compressors is barely achievable with metal.

Get Ready for Hydrogen

We at Greene Tweed have been manufacturing high-performance elastomers, thermoplastics, composites, and engineered components that can withstand harsh industrial conditions. We are ready with a wide range of material solutions that solve these hydrogen challenges. Here are the three major pieces of equipment in the Hydrogen supply chain that can benefit immensely from our material solutions:

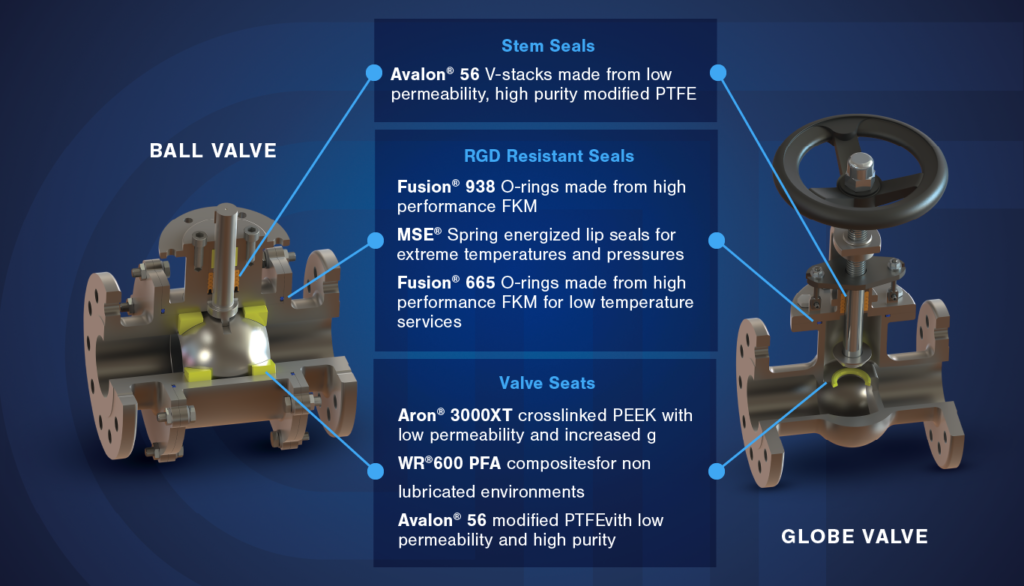

Valves

Valves are safety-critical components when producing or handling hazardous fluids. And hydrogen poses a few unique challenges. It is an extremely light and low-density gas. This means that it can penetrate any type of polymer or metal, causing leakage. “Permeation is a huge problem with Hydrogen and that’s why it is critical to select products made of materials with minimal permeability to reduce leakage. For instance, cross-linking a material like PEEK could help to lower diffusion coefficient and enhance performance in hydrogen environment by reducing permeation,” says Kerry Drake, Technology Manager at Greene Tweed. Arlon® 3000XT crosslinked PEEK may therefore be an excellent solution for valve seats in Hydrogen service. Low lubricity of hydrogen molecules can generate valve seats wear and friction issues. For these non-lubricated environments, Greene Tweed offers WR® 600, a PFA composite with unique dry-running properties, and Arlon® 3000XT, the only cross-linked PEEK available in the market.

When combined with high pressure, hydrogen permeation can generate Rapid Gas Decompression (RGD) issues. Greene Tweed recommends RGD-resistant Fusion®938 O-rings or MSE® spring energized lip seals for extreme temperatures and pressures. Permeation issues can also occur at low temperatures, too, and Fusion®665 O-rings are best suited to overcome such problems.

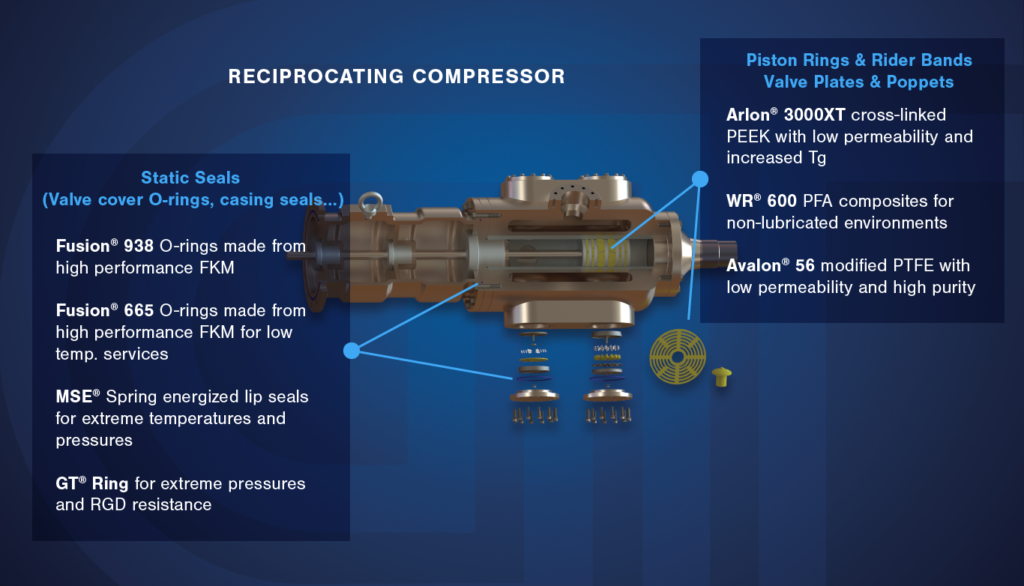

Compressors

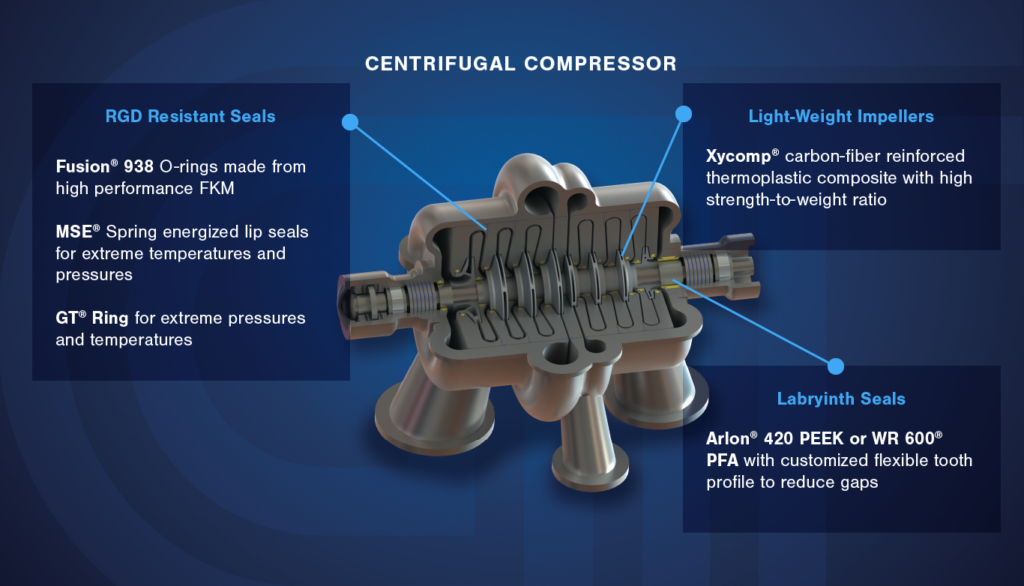

Compressors are critical to storing and transporting hydrogen safely and cost-effectively. “Compressors are one of the most critical equipment to transport the increasing amount of hydrogen that will be required to properly support the expected rise in hydrogen demand,” says Allienne. But designing new compressors or upgrading current compressors for hydrogen services often present technical challenges not typically seen with other gases, he adds.

For any types of hydrogen compressors, Greene Tweed engineers recommend Fusion® 938 O-rings for RGD resistance and Fusion® 665 O-rings for low-temperature services. In reciprocating compressors, our Arlon® 3000XT cross-linked PEEK, WR® 600 composites, and Avalon® 56 modified PTFE are a great choice in piston rings and rider bands as well as valve plates.

While designing a centrifugal compressor for hydrogen service, engineers need to ensure a high operating speed for the impeller. The maximum achievable impeller tip speed depends on the material used to construct it. Greene Tweed recommends Xycomp® carbon-fiber reinforced thermoplastic composite with a high strength-to-weight ratio. For sealing elements, RGD-resistant Fusion® 938 O-rings and MSE® spring energized lip seals for extreme temperatures and pressures are best suited.

Electrolyzers

Green hydrogen, a potentially carbon-free fuel, is critical to decarbonizing the global economy. What makes green hydrogen possible are electrolyzers that split water into hydrogen and oxygen using electricity that comes from sources like wind and solar. To produce emission-free hydrogen, electrolyzers need material solutions that can withstand challenges, such as material outgassing, chemical compatibility, or degradation of mechanical properties at increased temperatures. Greene Tweed has developed a portfolio that includes materials to enhance the performance of fuel cells and electrolyzers. These include Arlon® 3000XT that provides chemical resistance better than standard PEEK while retaining the mechanical properties of standard PEEK at a higher temperature. Moreover, it offers permeability 200 times lower than standard PEEK. Greene Tweed’s Chemraz® seals are ideal for their exceptional chemical compatibility, low outgassing properties, and high-temperature capabilities.

Testing Matters

How do we know that our material solutions work with hydrogen? We are actively testing our materials extensively at several independent laboratories to ensure that our solutions can withstand the challenges associated with hydrogen. So far, results from tests including high pressure cyclic exposure tests and permeation tests show our materials and solutions are ready to support and empower hydrogen infrastructure.