The Future of Energy Transition Starts with Safer Battery Enclosure

When batteries overheat, only the strongest enclosures survive. Rigorous lab tests show which materials stand up to the heat.

Battery energy storage plays a crucial role in the global energy transition. It provides a stable electricity supply from renewable energy sources and supports electrification toward decarbonization across multiple industries. As adoption grows, so do the challenges about safety and reliability.

Batteries often contain reactive components, such as lithium metal and flammable electrolytes. Physical damage or electrical failure can trigger a potentially catastrophic event. In short, thermal runaway, internal short circuits, mechanical damage, and overheating pose serious risks, including fire, explosion, and the release of hazardous materials. To mitigate these risks, robust battery enclosures are critical, serving to protect cells physically, manage heat, and contain potential failures, playing a central role in the overall safety and performance of energy storage systems.

Arlon® 3160XT Outperforms in Safety Test

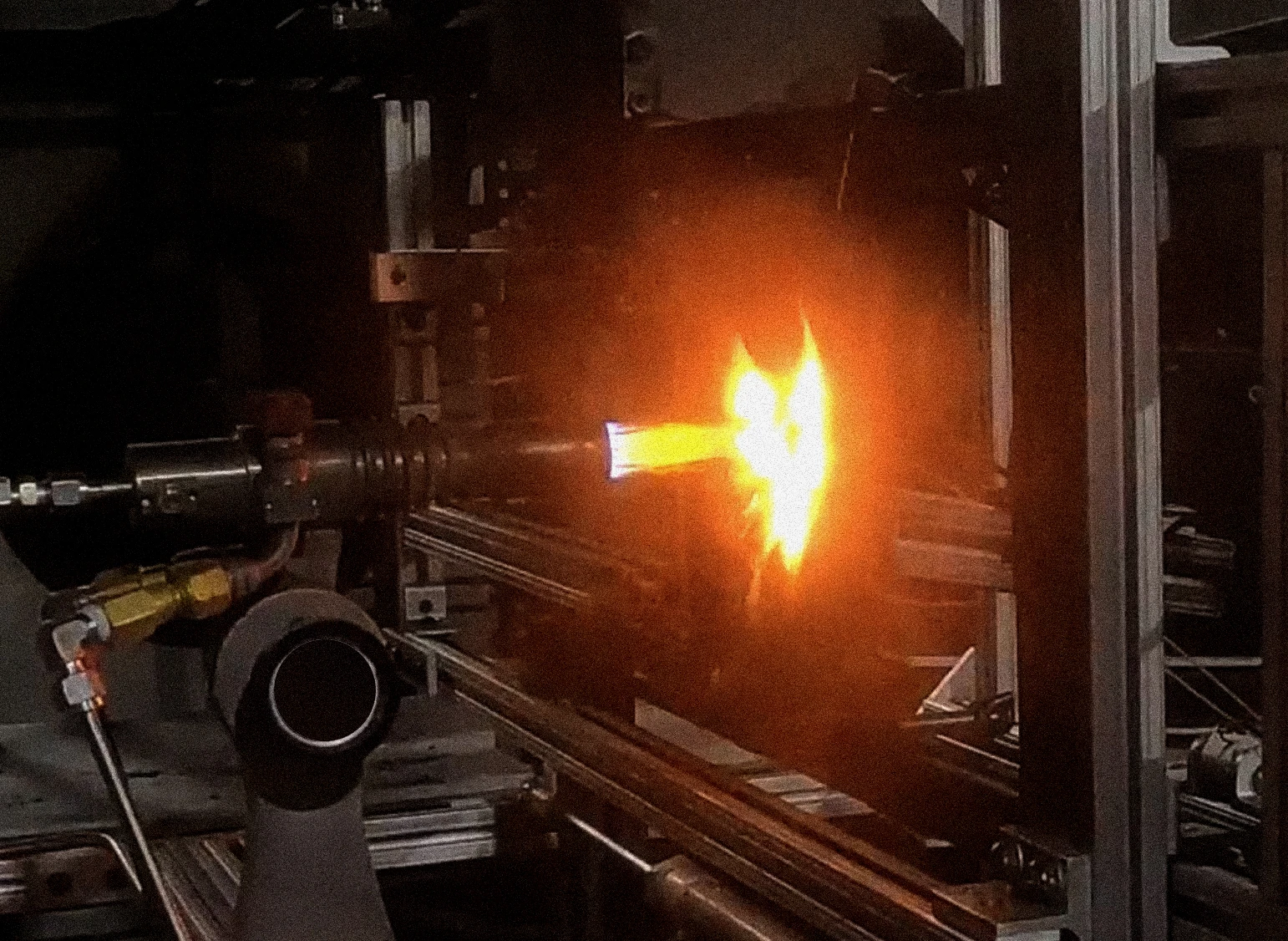

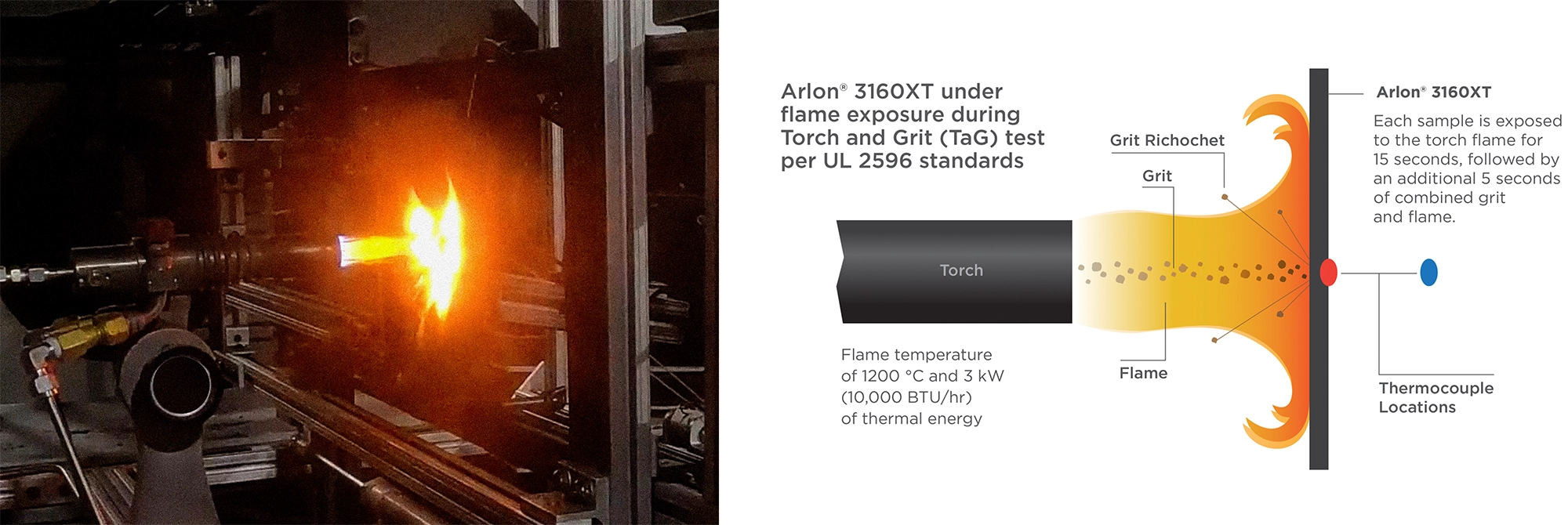

Understanding the critical role of battery enclosures, Greene Tweed conducted rigorous testing on Arlon® 3160XT, its proprietary glass-reinforced, cross-linked PEEK material, against standard PEEK material, using the Torch and Grit (TaG) test under UL 2596 standards. This test is widely recognized and used as a standardized screening test to evaluate the performance of battery enclosure materials. It simulates extreme abuse and failure conditions a battery enclosure would face during a thermal runaway event, making it essential for validating the safety and resilience of battery packs.

This test uses a specially designed torch that can deliver a precisely measured amount of heat, resulting in a flame temperature of 1200 °C and 3 kW (10,000 BTU/hr) of thermal energy, while dispensing a predetermined amount of grit to simulate particulates from battery failure. During the test, each sample is exposed to the torch flame for 15 seconds, followed by an additional 5 seconds of combined grit and flame. This 20-second cycle is repeated 10 times or until the sample fails. At the point of breach, the final surface temperature on the far side of the sample is recorded, offering insights into the material’s performance under extreme conditions.

Arlon® 3160XT greatly outperformed standard PEEK in these tests, showing better thermal protection performance with a 38% increase in time to failure and an 18% reduction in surface temperature at the point of breach, compared to standard PEEK. This cooler surface temperature means far less heat is transferred to nearby components. (Please refer to box below for a scientific explanation)

In fact, 90% less heat is transferred from the test coupon's backside surface to a second thermocouple that is offset some distance to represent an internal component within an enclosure. “The extended time to failure is a critical indicator for safety, while the reduction in surface temperature significantly reduces the radiative heat transfer to interior components in the event of a thermal runaway,” said Sam Hippe, Thermoplastic Product Development Engineer.

Samples tested to failure: Arlon® 3160XT displays a smaller hole size with no melt around it and a reduced heat-affected area, indicating an improved thermal performance, compared to standard PEEK.

Choosing the right materials for battery enclosures is critical to ensure safety, durability, and performance. Materials must strike a balance between strength, fire resistance, electrical insulation, and weight to protect cells under various conditions. Advanced materials like Arlon® 3160XT offer a high-performance solution, combining lightweight durability, corrosion resistance, and superior electrical insulation properties, enabling safer and more efficient designs while supporting the evolving battery demands of electric vehicles, grid storage, and other applications.

Advancing Battery Safety Together

At Greene Tweed, we combine decades of industry expertise with innovative engineering to deliver materials that meet even the most demanding requirements. Whether you’re developing cutting-edge solutions for battery or energy storage technologies, our advanced materials can help optimize performance and enhance safety.

From custom designs tailored to your unique needs to proven materials like Arlon® 3160XT, we are committed to helping you achieve your goals. Contact us today to learn how Greene Tweed can support your battery projects and drive your success.

Understanding Science

Heat transfer through radiation depends on the surface temperature to the 4th power (q = σT⁴A). A small drop in surface temperature can dramatically reduce the amount of heat radiated. In this case, Arlon® 3160XT reduced radiative heat transfer by 90%, making it far better at protecting internal components during thermal events.