Semiconductor

Industries - Semiconductor

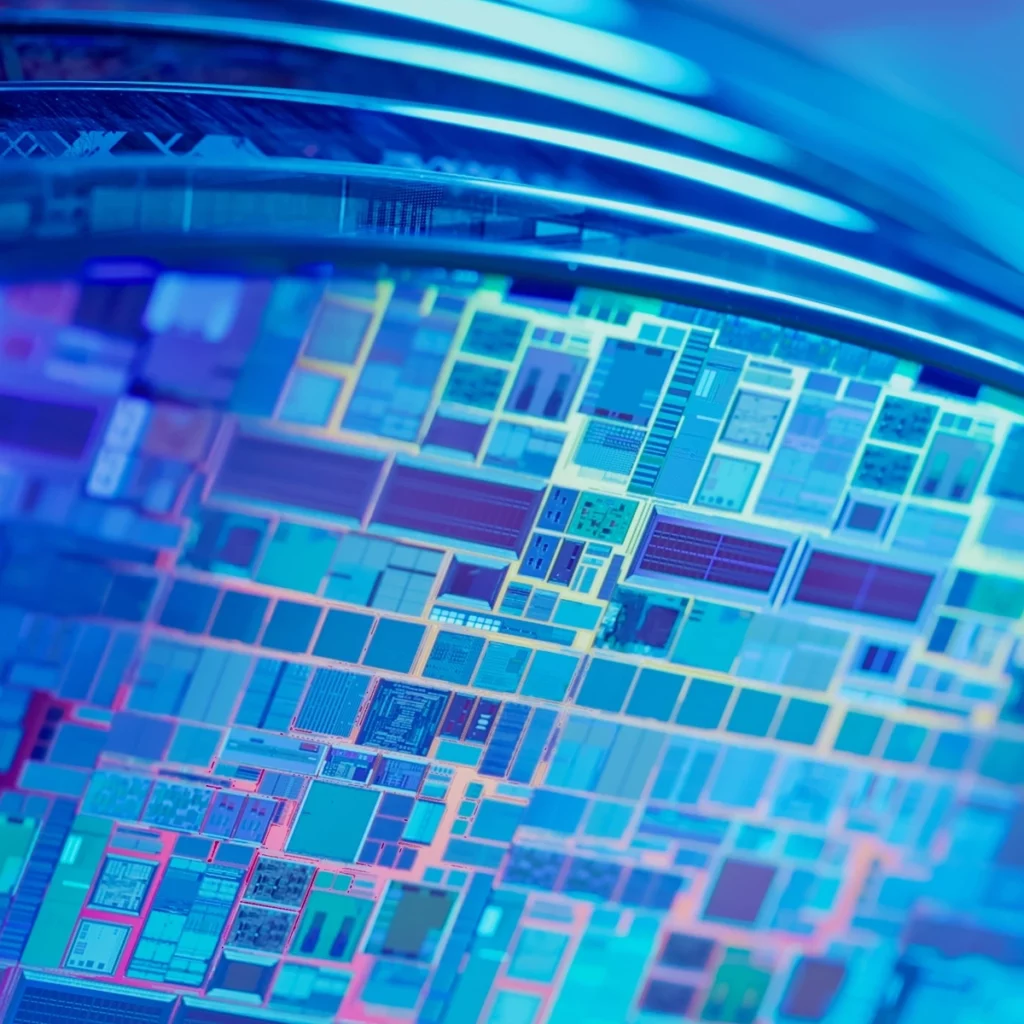

Unparalleled Performance for Semiconductor Fabrication

Expert Innovation

Greene Tweed sealing solutions combat the harsh plasmas and chemicals in wafer fabrication processes, resisting wear and tear from cleaning, patterning, and deposition.

Years of experience in Semiconductor applications

Greene Tweed solutions deliver proven performance for leading semiconductor fabs, foundries, and OEMs.

Greene Tweed remains an innovator, keeping pace with the explosive advancements of the semiconductor industry. Chemraz® seals withstand the plasmas used in cutting-edge deposition and etch wafer processing. ONX® 600 composite components resist harsh chemicals used in semiconductor manufacturing. Our expert solutions include bonding, encapsulation, and coating capabilities for extra protection.

Expert Application Engineering

Performance Under Pressure

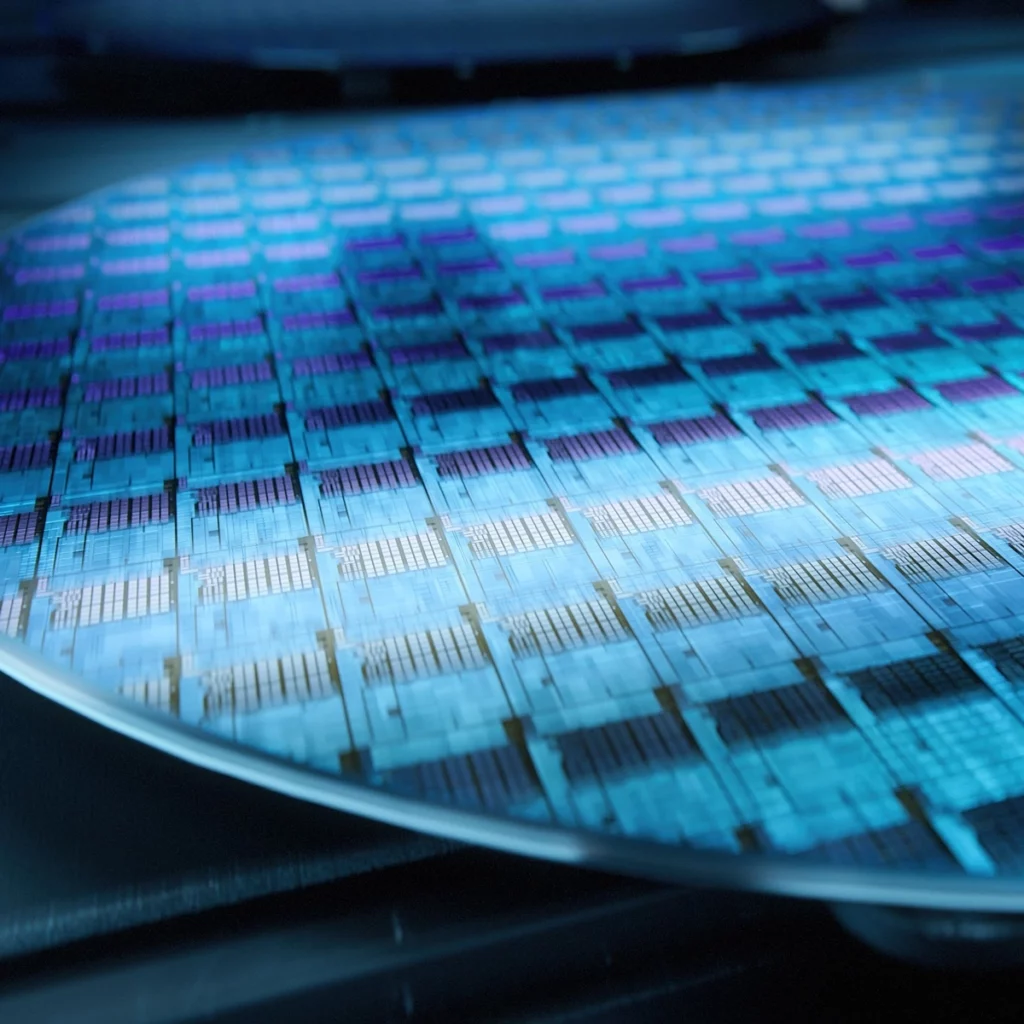

Etching

When purity is a must, Greene Tweed offers a range of solutions for the dry etch vacuum environment:

- Seals

- O-rings

- E-seals

- Avalon® shields for BSV doors

- Focus rings

- Mechanical fasteners

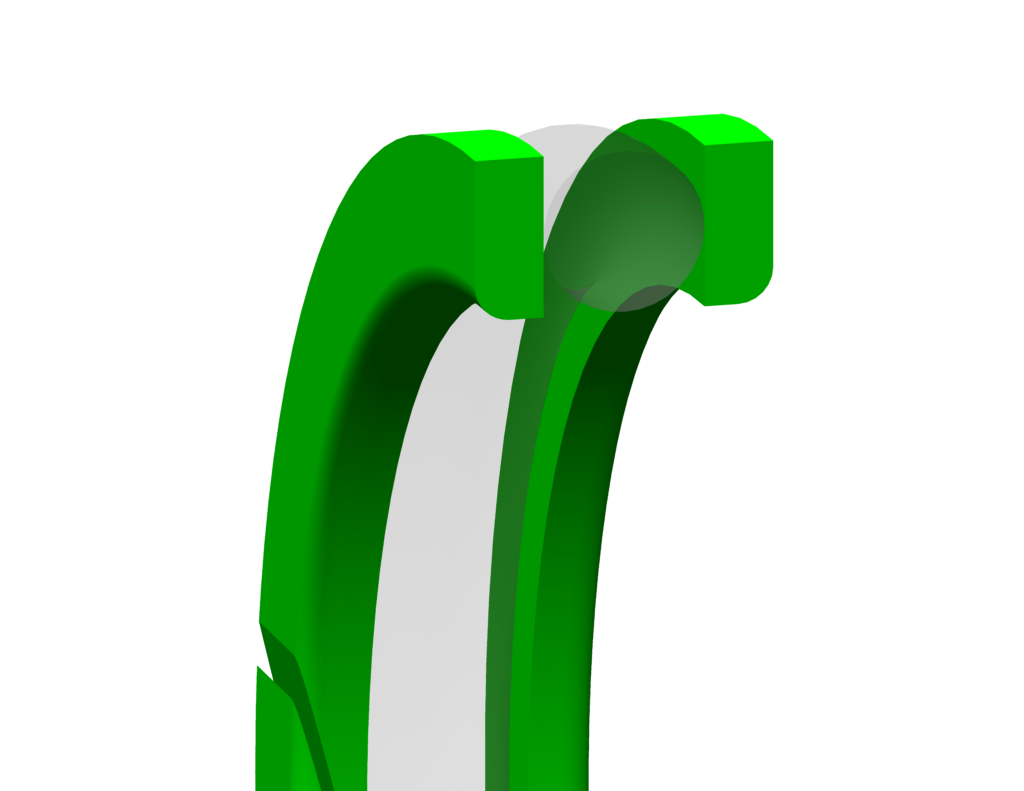

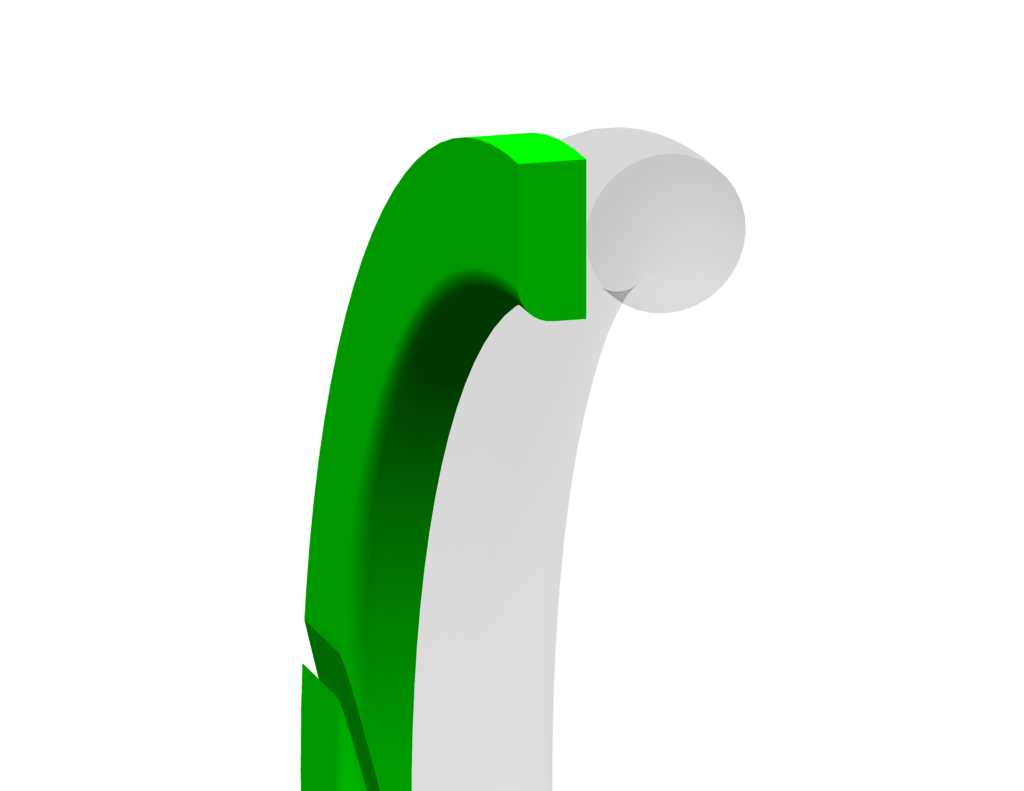

Improve Sealing Integrity

Valve Seals

Having to constantly replace worn out components is expensive and leads to unnecessary downtime. Greene Tweed’s custom semiconductor fabrication valve sealing solutions reduce MTBR (mean time between repair)

- Improve sealing integrity and reduce wear with PTFE shields

- Simplify installation and avoid time-consuming O-ring replacement with Bonded Slit Valve Door (BSV) solutions that allow for replacement of a few bolts to complete BSV door assembly

Greene Tweed’s expansive portfolio features materials includes Chemraz® bond seals for aluminum or stainless steel doors. This simplified design combines the door and seal into one piece and lasts up to 10x longer than typical perfluoroelastomer O-rings.

Turn up the Temperature

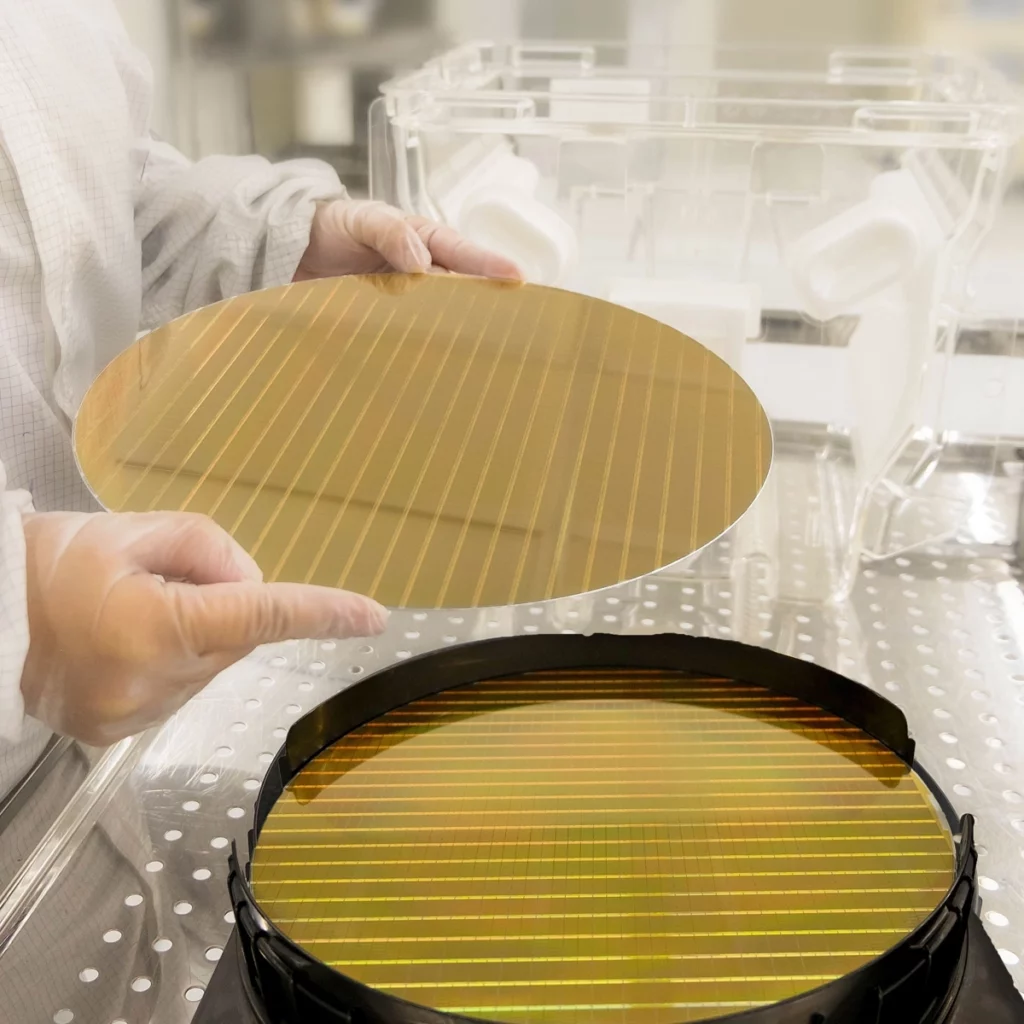

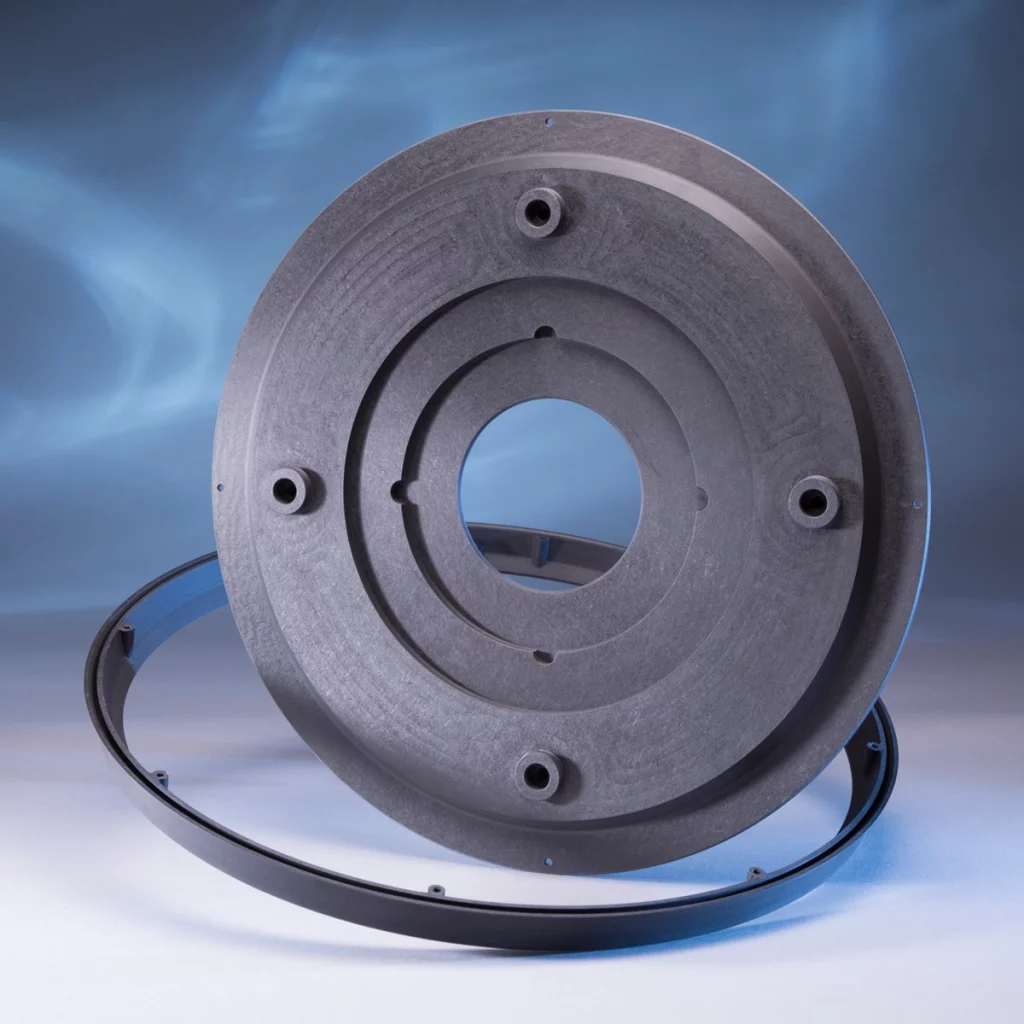

Wafer Handling

Wafer handling applications are subjected to high temperatures and strong acids. Greene Tweed’s ONX® 600, a fluoropolymer-based, carbon-fiber-reinforced composite, is a high-strength, high-purity material built to handle these harsh conditions.

Our experts design components like wafer-handling pads (fangs) for robots that transfer wafer during processes like doping, ion implantation, etching, and thin-film deposition to:

- Avoid sticking to the robot blade.

- Prevent wafer from flying off the robot blade.

- Give high-temperature endurance for hot wafers.

- Provide wear resistance on the robot blade.

- Reduce sticking with proprietary surface finishes on pads.

Boost Semiconductor Production

Electroplating

Enhance performance, extend seal life, and reduce sticking with Greene Tweed sealing solutions.

The Enduro™ LF10 is a thin conformal, PTFE-based coating that fortifies components in manufacturing equipment like elastomerics, thermoplastics, or metals.

By maximizing wafer surface, Greene Tweed edge exclusion products let you process more chips.