Three Tips to Extend your Seal’s Life in Semiconductor Applications

Global semiconductor shortage, coupled with sustained demand, is putting tremendous pressure on chipmakers to boost capacity. While semiconductor manufacturers are stepping up their efforts to increase output and the government is providing funding with CHIPS Act and FABS Act to mitigate long-term challenges, these are unlikely to solve immediate capacity constraints. For now, almost all chipmakers are focused on maximizing yield and productivity to meet customers’ demands.

Equipment maintenance and proper use of spare parts/consumables are crucial to keep the fabs running. Careful material selection, design and proper installation can help avoid leaks and other seal failures that can slow, or even stop production, and lead to productivity loss. Greene Tweed has been supporting critical sealing components, such as Chemraz® FFKM seals, to the industry for over 30 years. We are a leader in the design, development and manufacturing of elastomer seals used in chipmaking production equipment.

Undoubtedly, longer seal service life will benefit fabs. One quick and easy way to ensure that seal lifetime is maximized is to follow some good installation practices. Many seal failures we see in the field are a result of improper installation, which are completely avoidable if some best-known methods are used . After extensively testing several seal materials over the past several decades, our engineering teams have developed best practices to prolong the life of O-rings in semiconductor applications.

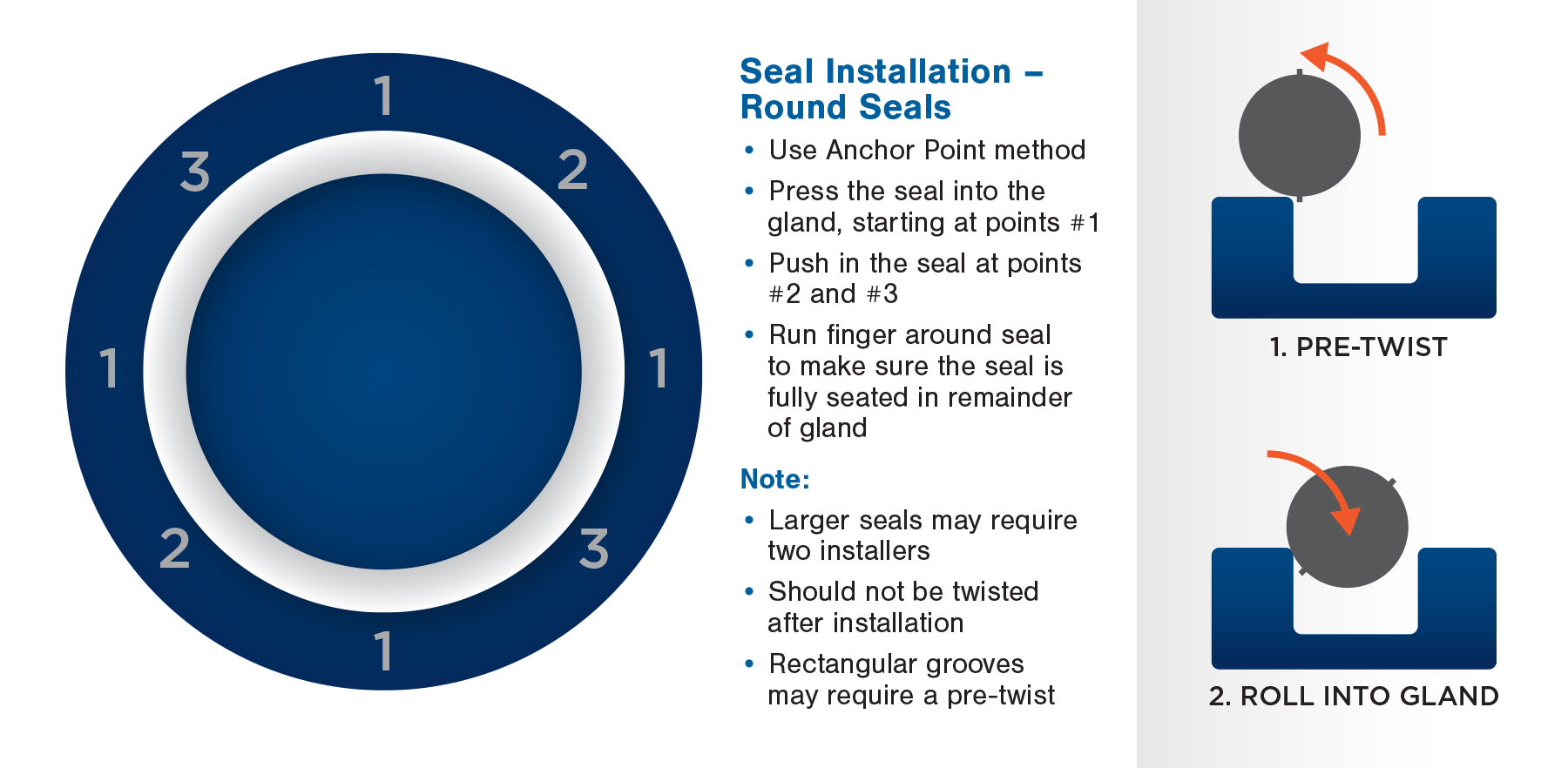

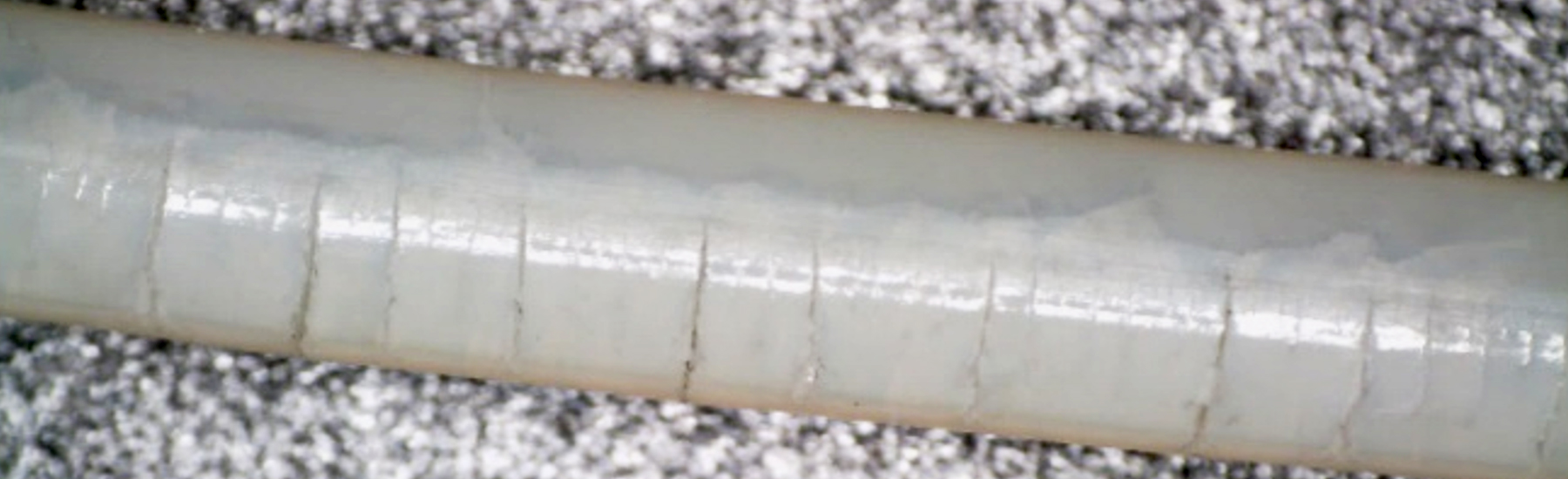

Installation – Avoid installing seals using a ‘racetrack’ approach; starting to press a seal into a gland at one point and going around in a circle until the seal is in place. This can lead to localized areas of high stretch, which can cause cracking in small sections of the over-stressed locations of the seal. This leads to premature leaking and reduces the expected lifetime if installed correctly.

Instead, use an anchor point method of installation, which more uniformly distributes the stretch on a seal.

Removal – Always use soft tools that won't scratch gland surfaces. It’s common to find metal picks on the fab floor that are used to pull out used seals. Unfortunately, the use of these tools can scratch gland surfaces and create gouges in gland hardware. These gouges inevitably create leaking issues in high vacuum environments and can be very tough to diagnose. Use of plastic tools is much preferred because they preserve the gland integrity as seals are changed over during routine maintenance.

Trouble areas – Some seals are just tricky to install, including small cross section seals like ESC seals and end effector pads. In situations like this, Greene Tweed has experience designing and providing unique installation tools to reduce the possibility of installation failure in the field.

Please contact Greene Tweed for information on how to deal with sealing problems.