Pump & Compressor Wear Components

Energy, Semiconductor

PRODUCT DESCRIPTION

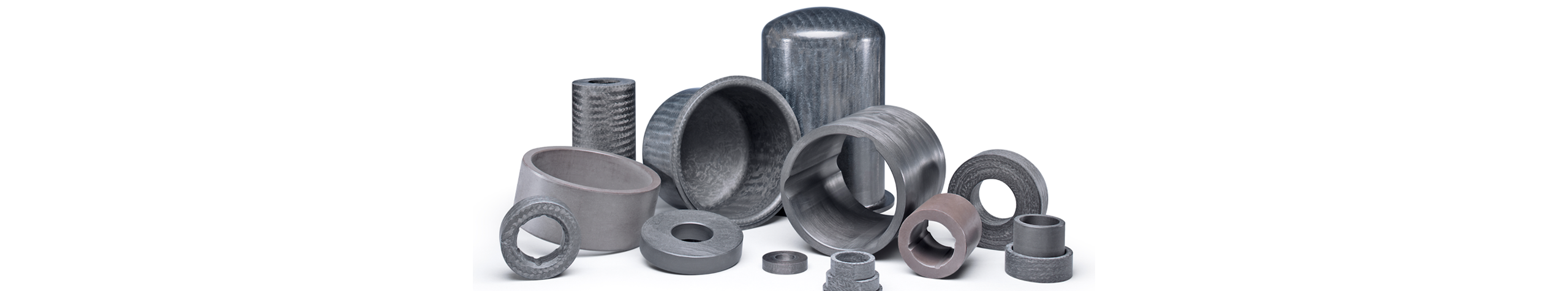

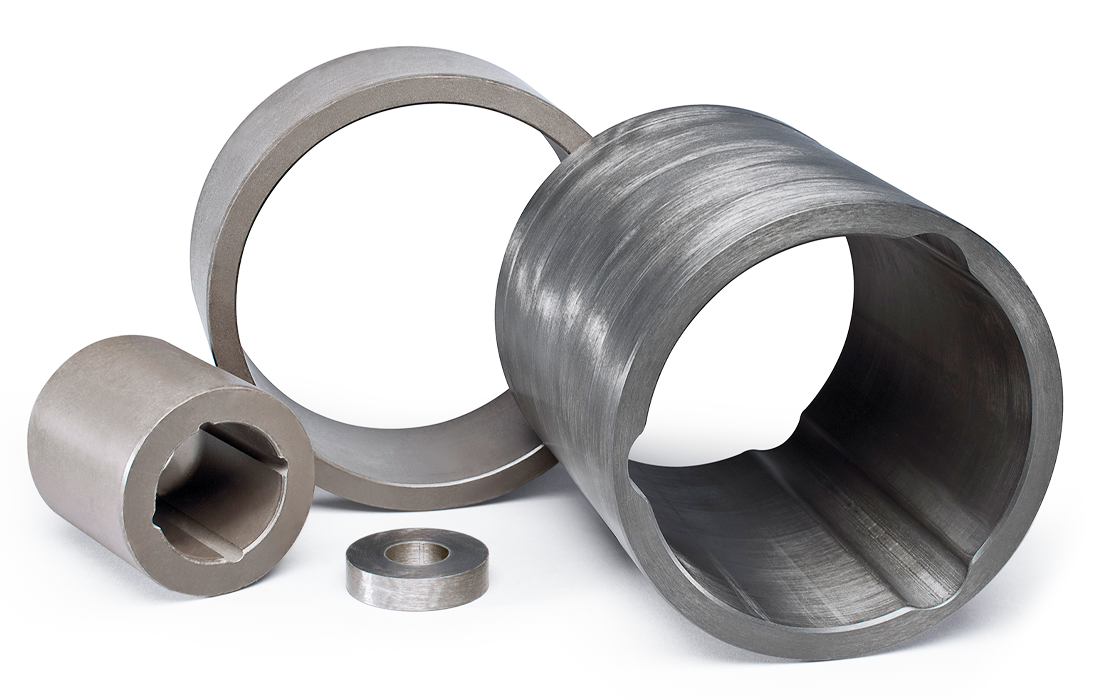

WR® & AR® Pump & Compressor Wear Parts

Greene Tweed thermoplastic composite wear parts are designed to enhance the safety and efficiency of your operations. Lighter and more resistant than their metal counterparts, our engineered components have become the industry standard for refineries, chemical plants, and power generation plants.

The non-galling, non-seizing performance and chemical resistance of WR® (Wear Resistant) composites cut down wear and friction. AR® (Abrasion Resistant) composites reduce downtime for pumps handling media-containing solids. All composites are built to withstand even your most extreme applications and volatile environments.

Features and Benefits

- Reduced repair and maintenance time

- Minimized chance of damage to critical components

- Reduced vibration due to tighter clearance

- Resistant to extreme temperatures and corrosion

- Improved reliability and efficiency of older equipment

Industries & Applications:

Pump Case Studies

WR® 650 Wear Ring - High-Efficiency Centrifugal Pump Solution:

One of the biggest chemical plant operators in Southeast Asia came to us with a challenge. Their existing centrifugal dryer circulation pump was an older model without a wear ring, and it needed an upgrade - view case study.

WR® 300/525/575 Materials - Three Materials in One Application:

A top OEM customer in the U.K. needed to remove asbestos bearing materials in the Hayward Tyler wet wound motor boiler feed pumps in a coal-fired power plant - view case study.

Greene Tweed engineered components are custom designed to be used for your most challenging applications. No matter how demanding the environment, our team works with you to determine the right solution for the job.

Applications include: