Improve Semiconductor Device Yields with Better Performing Seals

Nick Piacente, Greene Tweed Technical Product Specialist

The global need for chips in everything from cars, cell phones, lightbulbs, and other electronics has driven an increase in chipmaking capacity, as evidenced with recent industry announcements of billions in new equipment purchases, and plans of global fab groundbreakings.

As we face an industry-wide chip shortage, device yields, a measure of fab efficiency, have never been more important.

Device yield can be directly affected by particles – unwanted foreign materials that could be a fraction of the thickness of a hair – and can contaminate wafers and adversely affect device yield. These particles are generated during semiconductor processing as a result of the aggressive plasma environments that are common in the industry, which erode consumable parts during use. The equipment and parts used to produce semiconductors are therefore scrutinized for particle generation, down to the smallest components found in equipment such as O-ring seals.

Greene Tweed, a manufacturer of high-performance sealing materials, has taken a proactive approach to ensuring the lowest particle-generating seals are available for use by fabs. To better screen materials for use, Greene Tweed has developed a particle testing procedure that combines plasma processing, dynamic cycling, and particle detection.

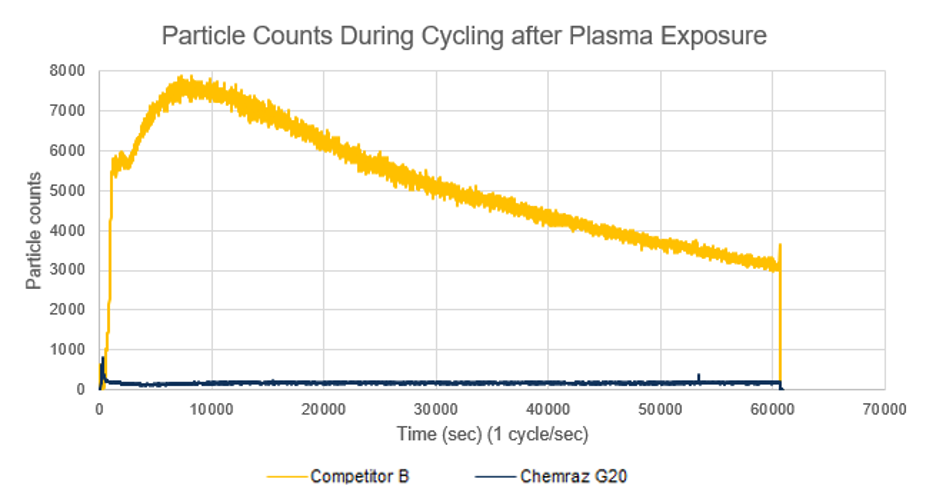

Greene Tweed's Chemraz® G20 shows improved particle performance in dynamic application testing when compared to competitor materials.

Elastomer seals are installed in an aluminum puck and subjected to aggressive NF3 or O2 plasma conditions at 250°C. The seals are subsequently cycled in an angle valve and heated to 250°C, while particles are measured in situ by a downstream detector.

This test method is used during development of next-generation materials to ensure materials used in the fab will help reduce particles generated and improve device yields.

Chemraz® G20, a newly commercialized perfluoroelastomer (FFKM) material, is one of the first materials to use this test in its development. As shown in the test result below, Chemraz® G20 produced orders of magnitude fewer particles when compared to a competitive benchmark material in a 60,000-cycle torture-test. Considering dynamic applications can be a major contributor to defect-related particles, improved O-ring performance can play a role in improving yields.

For more information about Chemraz® G20, or to learn how Greene Tweed can help you with your sealing problems, please contact us by using the form below.