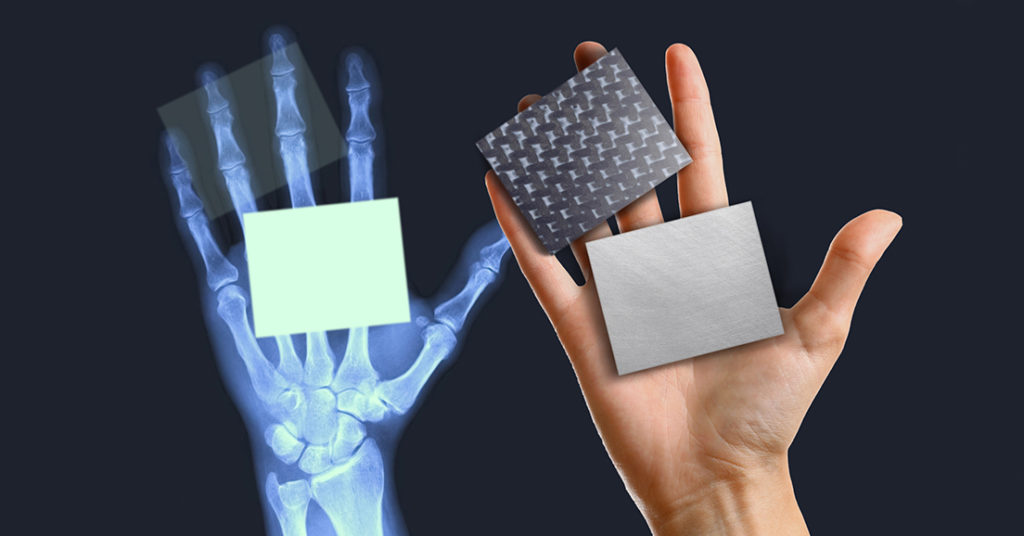

Lightweight and Highly Radiolucent Material Improves Performance in Surgical and Medical Treatments

Tony Young, Greene Tweed Field Engineer, Structural and Engineered Components Division

Improved equipment and lower level radiation requirements have increased the use of x-ray technology for surgical procedures and medical treatment. Traditionally, many applications used metals, such as aluminium, stainless steel, and titanium, for structural components used within the medical industry; however, these metal materials obstruct x-rays.

Through the use of carbon fiber thermoplastics, Greene Tweed’s Orthtek® products provide the necessary mechanical performance and are transparent to x-rays, which is critical for repeated use of surgical devices and external fixtures.

Used for demanding medical and biotechnology applications, Orthtek is high-strength, low-weight, corrosion-resistant, and provides an ideal solution for high-performance metal replacement. While Orthtek radiolucent products can provide mechanical properties comparable to metals, they are also five times lighter than stainless steel.

Orthtek products provide a range of application solutions to meet the diverse performance and Life Science industry needs. All Orthtek products are engineered using selective carbon fiber reinforcements and thermoplastic polymers. These materials provide superior strength to weight performance, combined with excellent toughness, making them ideal for applications such as nail guides and targeting devices used during the repair and alignment of fractures.

Radiolucent Orthtek enables a surgeon to take x-rays without moving the patient during surgery. Greene Tweed has the capability to make finished Orthtek products that incorporate metallic hardware, such as the targeting devices and fixtures shown in the above picture.

For more information about Greene Tweed’s Orthtek products, or to learn how Greene Tweed can help you with your Life Sciences and Structural Components needs, click here.